What Is a Gun Nozzle?

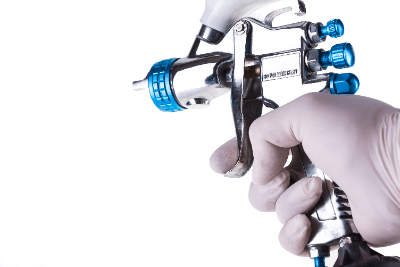

Gun Nozzles are specific nozzles that are primarily used in connection with a hose.

It has a convenient shape, especially in the form of a pistol, for manually discharging liquid or gas supplied by a hose. The handle is equipped with a trigger, and the liquid or gas can be discharged by pulling this trigger lever.

There are two types: manual and auto-stop. The latter is characterized by a function that detects the liquid level and automatically stops the machine.

Uses of Gun Nozzles

Gun Nozzles can be used by extending a hose from a high-pressure washer or pump and connecting it via a socket. If the emissions are gaseous (e.g., air), an air hose and compressor can be used together.

They are mainly used in situations where liquids or gases are supplied manually, such as when you want to spray water on a field, wash a car with warm water, or dry paint using air.

Both manual and auto-stop types can be fitted with a flow meter, which is utilized when the liquid needs to be separated or the discharge volume needs to be measured.

Principle of Gun Nozzles

There are two types of gun nozzles: manual type and auto-stop type, but the basic construction is much the same for both types.

1. Manual Gun Nozzle

Inside the Gun Nozzle is a channel for liquid or gas to pass through, and a valve closes the channel when the lever is not pulled. When the lever is pulled, a pin is raised in conjunction with the lever, pushing the valve inside the Gun Nozzle upward and opening the channel.

As a result, liquid or gas supplied to the Gun Nozzle can be injected from the tip of the nozzle.

2. Auto-Stop Gun Nozzle

A liquid level detection sensor is built into the auto-stop Gun Nozzle, and a hole is drilled in the tip of the nozzle for detection.

For example, when filling a tank with gasoline, and the tank is not filled, the sensing hole at the tip will not be blocked. Air flows inside the Gun Nozzle, and when the tank is full, the nozzle tip is blocked with gasoline, and air cannot flow inside the Gun Nozzle, creating a vacuum.

The built-in sensor then detects this vacuum and pushes up the valve on the Gun Nozzle, automatically closing the flow channel.

Types of Gun Nozzles

There are many different types of Gun Nozzles. Each is designed for a specific task or environment, and understanding their characteristics will help in selecting the appropriate nozzle.

1. Classification by Material

Gun Nozzles are made of a wide variety of materials, including plastic, aluminum, and stainless steel. Each material has different properties such as durability, light weight, and corrosion resistance.

2. Classification by Shape

Gun Nozzles also come in a wide variety of shapes. It is important to select the most suitable shape for each application, such as straight, angled, narrow-tipped, or capable of spraying over a wide area.

3. Classification by Flow Control Function

Some nozzles can control the flow rate. These nozzles are equipped with a flow control knob that allows delicate control of the amount of liquid or gas discharged.

How to Select a Gun Nozzle

The choice of Gun Nozzle depends largely on the purpose of use and the environment.

1. Purpose of Use

The most important factor in selecting a Gun Nozzle is what it will be used for. Whether for spraying liquid, cleaning, ventilation, or spraying heat, the appropriate nozzle should be selected according to the purpose.

2. Durability

Durability is a major factor in the choice of Gun Nozzle material. If the gun nozzle is to be used frequently or if it is to handle high-pressure or high-temperature liquids or gases, it is necessary to select a material with high durability.

3. Flow Control or Not

For jobs that require flow control, choose Gun Nozzles with flow control. Nozzles with adjustable spray volume and jetting force are effective for more precise work.

4. Ease of Handling

Finally, the ease of handling the Gun Nozzle is an important selection criterion. The shape of the handle, weight, size, and other factors should be chosen to suit your hand.