What Is a Digital Differential Pressure Gauge?

A Digital Differential Pressure Gauge is a device that measures and digitally displays the difference in pressure between two points.

It is sometimes called a manometer. The main features of a Digital Differential Pressure Gauge are its simplicity, which allows differential pressure to be measured simply by connecting the two points to be measured with a measuring tube, and its small size and light weight. Many products are available for both gases and liquids.

They can be used for a wide range of applications, from relatively large differential pressure, such as air pressure in air conditioning equipment, to small differential pressure in clean rooms, and can also be used for a wide range of ranges and resolutions. The battery-powered type, which does not require wiring, is used for monitoring and recording equipment, while the type with an alarm device is used for maintenance such as filter replacement. Some of them can measure flow rates using pitot tubes.

Applications of Digital Differential Pressure Gauge

Digital differential pressure gauges are used in a wide range of applications due to their broad measurement resolution. Typical applications are as follows

1. Performance Check of Air Conditioning Equipment

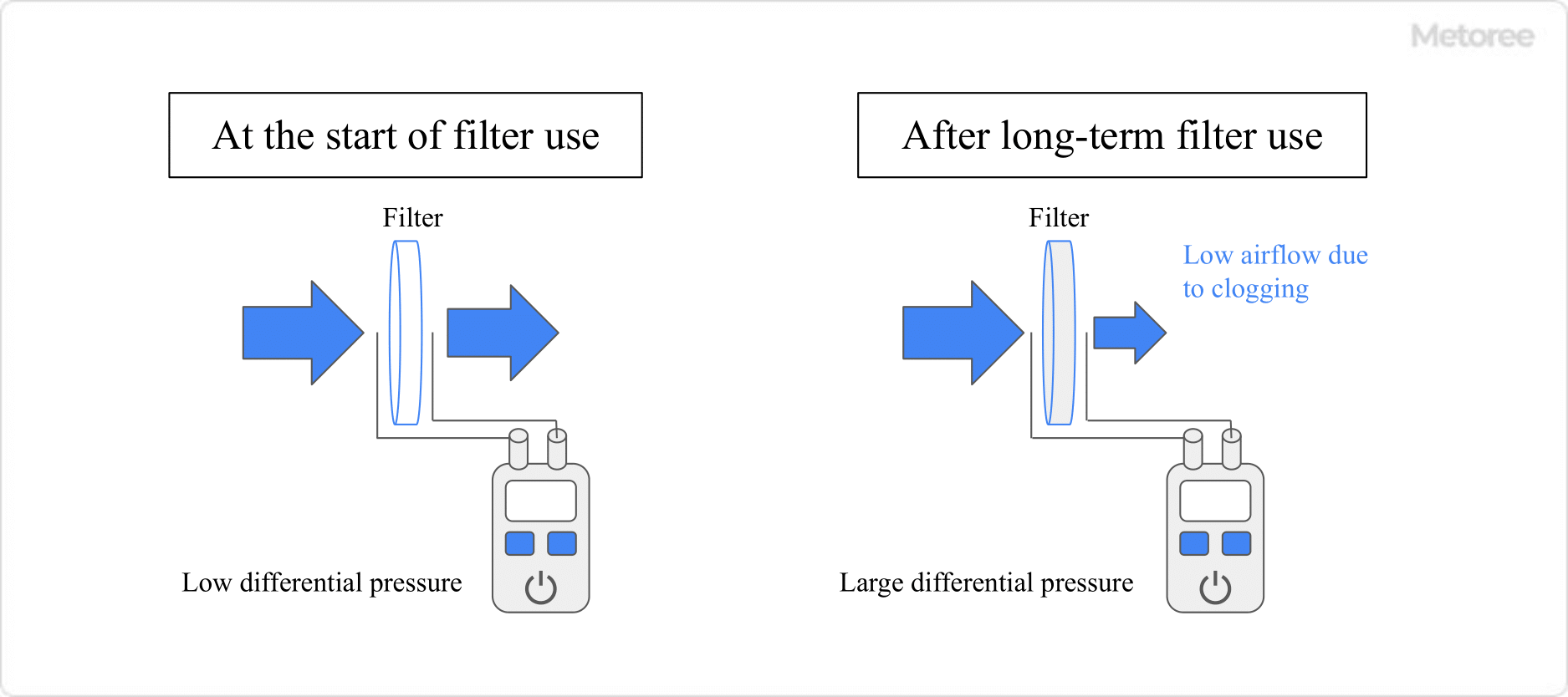

Figure 1. Maintenance of filter deterioration

Air conditioning equipment includes ducts, fans, and filters. As shown in Figure 1, the performance of filters deteriorates due to clogging after long-term use.

As clogging of the filter progresses, the differential pressure before and after the filter increases, so the performance of the filter can be checked using a differential pressure gauge.

2. Environmental Measurement in a Clean Room

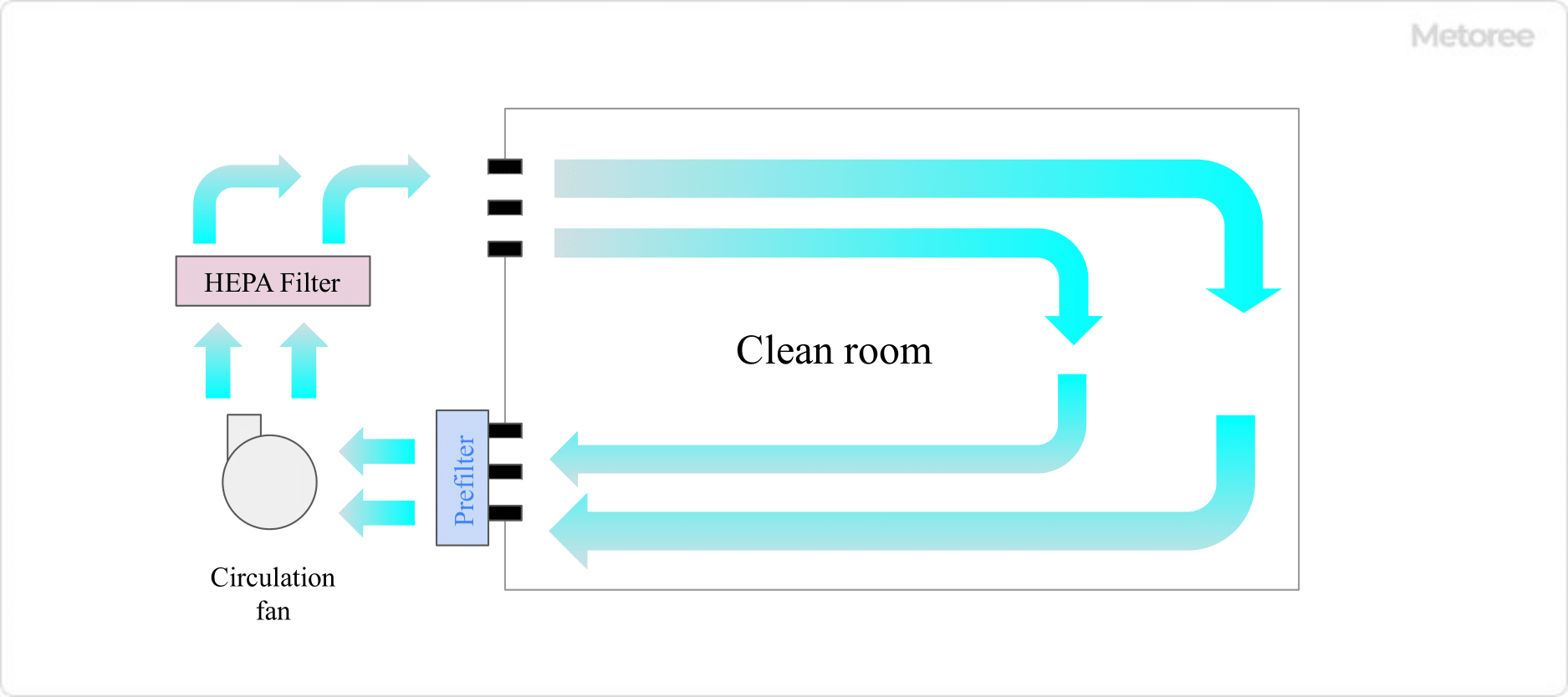

Figure 2. Schematic diagram of a clean room

In a clean room, it is important to maintain air cleanliness. Air is constantly circulated, and filters are used to remove dust and other particles to maintain cleanliness. It is important to check the performance of the filter using a differential pressure gauge.

The inside of the clean room is kept at positive pressure (higher than 1 atmospheric pressure) to prevent dust and other contaminants from being drawn in from outside the clean room. A differential pressure gauge can be used to check whether positive pressure is maintained. Especially when some kind of exhaust system is installed in the clean room, it is essential to check the positive pressure because negative pressure is likely to occur.

3. Level Measurement of Large Sealed Tanks

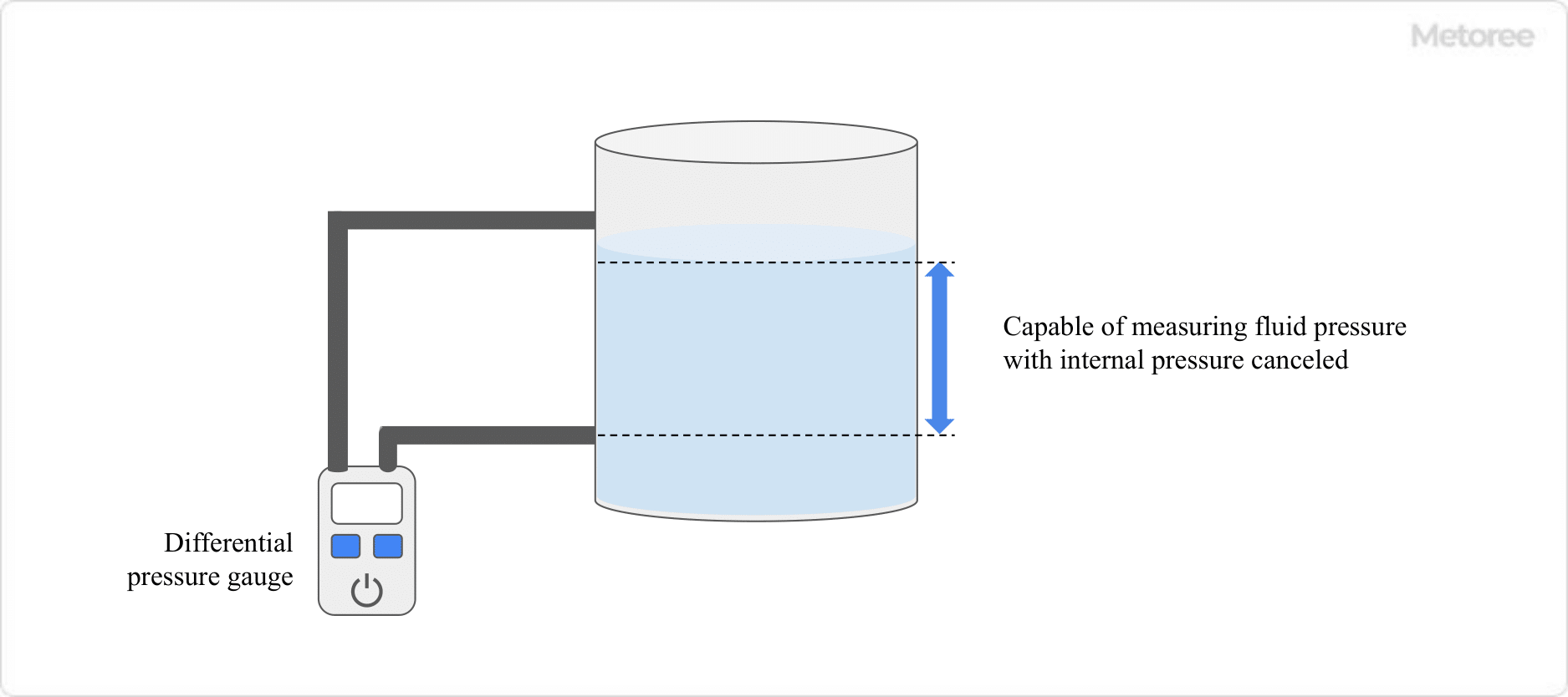

Figure 3. Measuring liquid level height in a sealed tank using a differential pressure gauge

A differential pressure gauge is also used to determine the level (height of the liquid surface) of a liquid in a closed tank. If the specific gravity of the liquid is constant, the pressure applied to the measuring surface is proportional to the level of the liquid, so the level can be determined by measuring the pressure.

However, in the case of a sealed tank, the pressure applied to the measurement surface includes the internal pressure of the tank top surface, so it is necessary to cancel the effect of the internal pressure. In such cases, a differential pressure gauge can be used to measure only the pressure due to the liquid.

Principle of Digital Differential Pressure Gauge

When pressure is applied to a pressure-sensitive element, the deflection of the element is measured as an electrical signal by the change in resistance due to the current flowing through the element. The relationship between the electrical signal and the displacement of the element is used to convert the measurement result into pressure. Digital Differential Pressure Gauge displays the difference in pressure between two points measured in this way as a digital value.

Since the Digital Differential Pressure Gauge has two measuring points, it measures the magnitude and direction of the deflection (displacement) caused by the pressure applied from the two measuring points in two directions. By measuring the direction, it determines which is the high pressure side and which is the low pressure side, and the difference in displacement is read as an electrical signal and displayed as a pressure difference.

Other Information on Digital Differential Pressure Gauge

About the Pressure-Sensitive Element

Embedded inside a Digital Differential Pressure Gauge is a piezoelectric element (piezoelectric element) as a pressure-sensitive element. A piezoelectric element is a passive element that uses the piezoelectric effect to generate a voltage in response to the pressure applied to a specific material. Crystal (synthetic quartz) and ceramics with strong magnetic properties are mainly used.

The piezoelectric element, which is the key to measurement, consists of a piezoelectric material with the piezoelectric effect sandwiched between two electrodes. The simple structure of the piezoelectric element has the advantages of being durable, resistant to deterioration, and lightweight.

There are many materials that possess the piezoelectric effect, and since materials for pressure-sensitive elements are being developed, products that enable more precise measurement are also being developed.