What Is Carrier Tape?

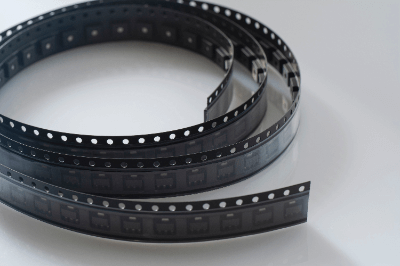

Carrier Tape is a tape used for transporting and storing electronic components, semiconductor semiconductor parts, and microchips.

Carrier Tape is a tape used for transporting and storing electronic components, semiconductor semiconductor parts, and microchips.

The main materials used are polystyrene resin and other resin-based materials and paper-based materials.

When handling microchips and other extremely small-sized components, semiconductors can be individually packaged on carrier tape, transported to an assembly plant, and then set on a component assembly machine for transport.

Demand for carrier tape is growing rapidly for packaging ultra-small chip-sized components due to the widespread use of mobile terminals and personal computers.

Uses of Carrier Tape

Carrier tape is used to package extremely small chip size components, which are rapidly growing in demand due to the proliferation of mobile terminals and PCs.

Paper products or embossed products are used depending on the size and application of the component to be packaged.

Examples of ultra-small chip size components include integrated circuits (IC), chip resistors, capacitors, coils, transformers, switches, connectors, relays, quartz crystals, LEDs, transistors, and diodes.

Principle of Carrier Tape

Carrier tape can be used to package minute components by changing the pocket shape to match the component.

Vacuum rotary forming enables sharp pocket forming with a small opening R and retention of firm vertical walls. In addition, it is formed with high precision to ensure that inserted parts do not roll around in the pocket.

Ribbed carrier tape provides ribs in the pockets to restrain component movement and prevent lead breakthrough. Also, to prevent device adsorption, a step is provided at the bottom of the pocket to float the device.

Transparent conductive carrier tape has excellent visibility, conductivity, and heat resistance. Being carbon-free, it is a clean product with low dust emission.

In recent years, environmental considerations have led to the development of environmentally friendly products such as recyclable carrier tapes and carrier tapes made from biomass plastics.

Carrier tape may be wound in reel form when packaging components. This is called a carrier tape reel.

Carrier tape reels are used to feed mounters, which are automated parts assembly machines. Carrier tape wound on a reel is an essential part of an automated assembly line because it can supply parts at high speed.

How to Select Carrier Tape

Depending on the size and application of the component, it is necessary to use either a paper product or an embossed product for carrier tape.

The following explains more specific selection methods:

1. Pocket Depth

The depth of the pocket used for carrier tape should be selected according to the height of the component. If the component protrudes higher than the pocket, it may be damaged during transportation. Conversely, if the pocket is too deep, the part will sway and may be damaged during transport. Selecting the proper depth will ensure safe transport of the parts.

2. Pocket Shape

It is important to select a pocket shape that matches the shape of the part. Ensuring that the part is held securely in the pocket will help protect the part from vibration and shock during transport. Also, depending on the shape of the pocket, it may be easier to remove the parts and set them on the mounter, leading to more efficient assembly work.

3. Conductivity

Some carrier tapes are required to be conductive. When carrier tape is charged, it attracts dust and dirt. For semiconductor components, dust and dirt can lead to performance degradation. Also, if static electricity builds up on the carrier tape and causes dielectric breakdown, an abnormal current will flow through the IC device, causing the component to fail. When inserting such components that are greatly affected by dust and static electricity, it is necessary to select a conductive carrier tape.

4. Dust Generation

Some carrier tapes must have low dust generation. For example, for precision components such as semiconductor parts and microchips, it is essential that there be no dust generation. If dust is generated, it will adversely affect the function of the component. For this reason, non-carbon transparent conductive carrier tapes, etc. are used.