What Is a Vacuum Gauge?

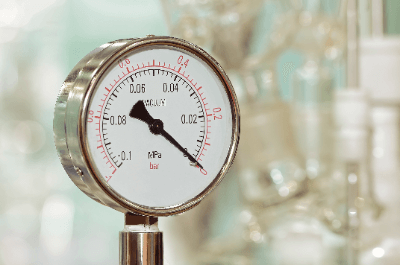

A vacuum gauge is a sensor used to measure the degree of vacuum in a given space.

A vacuum gauge is a sensor used to measure the degree of vacuum in a given space.

Depending on its purpose, either a partial pressure vacuum gauge or a total pressure vacuum gauge is selected. There are also many measurement methods, and the range of vacuum that can be measured varies depending on the difference between them.

Examples of Vacuum Gauges Applications

Vacuum spaces are often used at manufacturing sites where high cleanliness is required, since there are infinitely few impurities, including moisture, in a vacuum space. Among these, vacuum gauges are installed in fluid circuits connected to chambers and quartz tubes that require vacuum reach control.

Vacuum gauges are often installed in plasma etching spaces in semiconductor manufacturing equipment and experimental facilities such as metallurgy and organic synthesis. Vacuum gauges are also used in situations where surface cleanliness is required, such as in ion beam equipment and evaporation equipment, where the surface of the object is processed.

Principle of Vacuum Gauges

There is a wide range of vacuum gauge types and measurement principles. Vacuum gauges successfully measure the momentum of a very small amount of gas molecules and convert it into gas density and degree of vacuum in space. The most commonly used vacuum gauges are the Pirani vacuum gauges.

The Pirani vacuum gauges are electrical resistance type vacuum gauges that calculate the electric current from the heat energy dissipated when the gas collides with the platinum wire through which the electric current flows. It calculates the pressure backward from that value. The micro-pressure is directly equivalent to the degree of vacuum.

How to Select Vacuum Gauges

There are many types of vacuum gauges, so it is necessary to select the vacuum gauge that best suits your purpose. It is important to fully understand the characteristics of each type of vacuum gauge, as they differ according to the type of application and measurement method.

In addition, since there are several types of vacuum gauges of various types, the selection should be made according to the vacuum level of the desired vacuum space to be measured. To guarantee the final vacuum attainment, one vacuum gauge is sufficient, but if you want to know the behavior of the vacuum pumping rate and other factors, multiple vacuum gauges must be installed.

Types of Vacuum Gauges

Vacuum gauges can be classified into several types in terms of application, measurement method, and measuring range.

1. By Application

Partial Pressure Vacuum Gauges

A partial pressure vacuum gauge is selected when the vacuum is to be measured only for individual gases, i.e., when two or more gases are mixed, the partial pressure is the pressure indicated by each gas.

It is used to analyze the quality of the vacuum since different types of gases have different properties at the same pressure. The most common partial pressure vacuum gauges are the mass spectrometer.

A mass spectrometer consists of an ion source, an analyzer, and a detection unit. By using an electric or magnetic field, it is possible to determine the pressure of each gas by observing only specific ions.

Total Pressure Vacuum Gauges

The total pressure vacuum gauges are selected when you simply want to measure the vacuum in a space. Since there are many types of vacuum gauges available depending on the measurement method, it is necessary to select the one that best suits your purpose.

2. Measurement Methods

There are three main types of measurement methods. There are three main types of measurement methods: methods that detect pressure itself, methods that use the transport phenomenon of gas, and methods that use the ionization phenomenon in gas.

Methods That Detect Pressure Itself

A U-tube vacuum gauge are differential pressure gauge that uses a glass U-tube, one end of which is evacuated to a vacuum, and the other end is sealed.

The U-shaped vacuum gauges are characterized by the fact that it is independent of the type of gas. The U-shaped vacuum gauges are unique in that it is independent of the type of gas, and is used as a calibration standard for other vacuum gauges because it allows absolute measurement of pressure.

Method Using Gas Transport Phenomena

Thermal conductivity vacuum gauges are vacuum gauges that utilize the transport phenomenon of gases. These vacuum gauges utilize the property that the thermal conductivity of a gas varies with pressure.

There are many types of thermal conductivity vacuum gauges, including Pirani vacuum gauges, thermistor vacuum gauges, and thermocouple vacuum gauges. The important point to note about thermal conduction vacuum gauges is that, at high vacuum, the effect of thermal radiation is greater than that of thermal conductivity. Therefore, thermal conduction vacuum gauges have the disadvantage that they cannot be used to measure high vacuum.

Method Using Ionization Phenomena in Gases

Penning vacuum gauges (cold cathode ionization vacuum gauges) and ion gauges (hot cathode ionization vacuum gauges) are vacuum gauges that use the ionization phenomenon of gases. Penning vacuum gauges use the discharge phenomenon in a vacuum to measure pressure. Although Penning vacuum gauges are highly durable, their sensitivity varies depending on the type of gas.

The advantage of the Penning vacuum gauges is that its circuit configuration is simple. On the other hand, the disadvantage is that penning discharges can be unstable, making it difficult to make very accurate measurements. Furthermore, if the surface is heavily contaminated, the amount of electrons emitted from the cathode is reduced and no discharge occurs, and it is difficult to initiate a discharge in a high vacuum condition.

3. Measurement Range

Pressure is divided into low vacuum, medium vacuum, high vacuum, ultra-high vacuum, etc., and the degree of vacuum measured depends on the type of vacuum gauge. Vacuum levels are classified into five categories according to the pressure range, as shown below. Pirani vacuum gauges can measure low to medium vacuum, and ionization vacuum gauges can measure medium to ultra-high vacuum.

- Low vacuum: 105Pa to 102Pa

- Medium vacuum: 102Pa to 10-1Pa

- High vacuum: 10-1Pa to 10-5Pa

- Ultra-high vacuum: -5Pa to 10-8Pa

- Extremely high vacuum: 10-8Pa or less