What Is Gun Drilling?

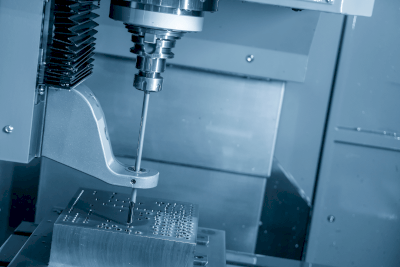

Gun drilling is a precision machining process used to create narrow, deep holes in a workpiece. Originally developed for drilling barrel holes in firearms, this technique employs a long, specialized drill bit.

Gun drilling is a precision machining process used to create narrow, deep holes in a workpiece. Originally developed for drilling barrel holes in firearms, this technique employs a long, specialized drill bit.

This method is notable for its ability to create small-diameter holes with high precision and linearity. It is effective on hard materials such as chrome molybdenum steel, carbon steel for machine structural use, and chrome steel.

Uses of Gun Drilling

Gun drilling is widely used in various industries to produce components with deep holes. Its applications include manufacturing parts for electrical equipment, railroad cars, aircraft, ships, automobiles, machinery (like spindles, shafts, and cylinders), injection machine nozzles, hydraulic equipment, semiconductor heat plates, LCD production equipment, construction machinery, and more.

Principles of Gun Drilling

The gun drilling process involves:

- A carbide cutting edge (drill blade)

- A shank (handle of the drill)

- A driver (part holding the shank and connecting to the machine)

The gun drill has a lubricant passage, with an outlet at the tip for injecting lubricant. Grooves along the carbide cutting edge and shank enable the ejection of machining debris. By rotating at high speed and injecting lubricant through the tip, the drill shaves material while expelling debris through the grooves.

This mechanism allows efficient debris removal during machining, offering greater efficiency than other deep-hole drilling methods. Additionally, the lubricant helps control temperature and reduce tool wear.

Gun drilling is particularly suited for small holes, typically ranging from 1 mm to about 30 mm in diameter, and is less effective for drilling larger deep holes.