What Is Carbon & Graphite Fiber?

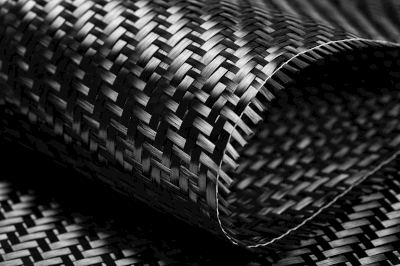

Carbon & graphite fiber, also known as carbon fiber, is a type of fiber composed entirely of carbon (C).

Two primary types of carbon & graphite fiber exist: PAN-based and pitch-based. These fibers inherit many properties of carbon, such as excellent heat resistance and electrical conductivity. Carbon & graphite fiber is highly valued across numerous industries due to its lightweight nature, strength, and hardness.

However, challenges related to its cost currently limit its usage in several fields.

Applications of Carbon & Graphite Fiber

Carbon & graphite fiber find extensive application as a substitute for metallic materials, leveraging their lightweight properties while retaining strength. Its flexibility, electrical conductivity, corrosion resistance, and flame retardance widen its utility.

Typically used in composite materials alongside resins, ceramics, and metals, carbon & graphite fiber is integral in various sectors. It is employed in aerospace for aircraft, rockets, and satellites, in medical equipment like prosthetics and wheelchairs, and notably in automotive manufacturing for improved fuel efficiency and weight reduction.

In addition, carbon & graphite fiber’s strength and elasticity make it popular in sports equipment such as golf clubs, tennis rackets, and bicycles. Its potential applications extend to architecture and civil engineering, where it may enhance earthquake resistance in concrete structures or replace steel frames and suspension bridge cables.

Types of Carbon & Graphite Fiber

Carbon & graphite fiber can be categorized based on the raw material:

1. PAN Carbon & Graphite Fiber

Made from carbonized polyacrylonitrile (PAN) fibers, PAN-based carbon & graphite fiber is prevalent in industrial and leisure applications. It typically consists of filaments with diameters ranging from 5 to 15 μm, bundled in regular or large tows.

2. Pitch-Based Carbon & Graphite Fiber

Derived from pitch, a solid residue obtained from crude oil distillation, pitch-based carbon & graphite fiber offers adjustable elasticity. It is categorized into mesophase and isotropic pitch fibers, each tailored for specific applications such as automotive brake pads or machinery requiring vibration resistance.

Production Methods of Carbon & Graphite Fiber

1. PAN-Based Carbon & Graphite Fiber

PAN fibers undergo oxidation at 200-300°C to create a cyclic molecular structure. Subsequent carbonization at temperatures exceeding 1,000°C converts the molecular structure into a carbon crystal. Further graphitization at temperatures above 2,000°C yields graphite fiber.

2. Pitch-Based Carbon & Graphite Fiber

Coal or petroleum pitch is converted into fibers, which are then sintered. Precursor fibers are obtained through a process involving melt-spinning, stabilization, flame resistance treatment, carbonization, and graphitization.