What Is a Steam Trap?

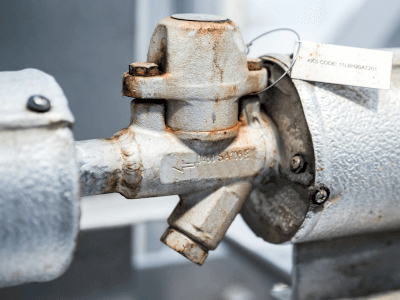

A steam trap is a device that separates and discharges condensate (water droplets) generated within steam systems.

In factories, steam flows through pipes. When these pipes come into contact with the outside air, their surface temperature drops, causing the steam to cool and condense. If this condensate mixes with steam, it can violently collide at bends, such as elbows, leading to a condensate attack and potential damage to the piping. Erosion can also occur when condensate strikes the impellers of blowers or turbines. Installing steam traps helps avoid these issues.

Uses of Steam Traps

Steam traps are essential in piping systems where steam is utilized. By installing a steam trap, it is possible to collect condensate within the steam, thus preventing erosion and water hammering.

As steam cools and condenses, its volume significantly decreases, potentially causing a vacuum that draws condensate together, resulting in impact damage.

This can lead to severe damage to the piping and connected equipment, making the prevention capabilities of steam traps critical.

Principles of Steam Traps

Steam traps can be mechanical, thermodynamic, or thermostatic. Their operating principle varies by type.

1. Mechanical Type

The mechanical type operates simply. When condensate enters, it causes a float or bucket to rise, opening or closing the valve. This type is easy to maintain, and its operation can often be verified by sound. However, it requires regular maintenance to remove any dust accumulation on the valve to prevent continuous steam leakage.

2. Temperature Difference Type

The temperature difference type operates on the expansion and contraction caused by the temperature differential between steam and condensate. It is divided into bimetal and bellows types. The bimetal type relies on the differing expansion rates of two metals, while the bellows type uses a bellows mechanism for movement.

3. Thermodynamic Type

The thermodynamic type operates based on the pressure differences in the chamber between the primary and secondary sides. The valve opens as the high-temperature condensate expands the bimetal, allowing condensate discharge. Once the steam flows, the pressure drop causes the valve to close, repeating the cycle as needed.

Types of Steam Traps

1. Mechanical Type

Mechanical steam traps, utilizing the specific gravity difference between steam and condensate, are categorized into bucket and float types. The bucket type includes inverted bucket (I.B. type) and standard bucket types, while the float type includes designs with levers.

2. Temperature Difference Type

The thermostatic steam trap, or thermal differential type, operates on the temperature difference between steam and condensate. It includes bimetal and bellows types.

3. Thermodynamic Type

The thermodynamic steam trap utilizes the thermodynamic properties difference between steam and condensate, further classified into disc type and external air-cooled types.

How to Choose a Steam Trap

1. Mechanical Type

The mechanical type, offering no condensate retention and featuring an energy-saving design, includes the scale-resistant bucket type and the quick-warming, pressure-difference-resistant float type. However, the mechanical type may be susceptible to freezing and is relatively large. The float type is vulnerable to water hammer, and the bucket type’s installation direction may be restricted.

2. Temperature Difference Type

The thermostatic type is quiet and water hammer resistant. It allows for controlled condensate discharge temperature and features good low-noise air discharge performance. However, due to its lower-than-saturated steam temperature operation, condensate may accumulate, leading to delayed valve closing and steam loss. The bimetal parts are prone to corrosion and fatigue, affecting durability.

3. Thermodynamic Type

Compact and lightweight, the thermodynamic type is resistant to freezing and can be installed in any direction. However, it is sensitive to external temperatures, which may lead to dry hitting and potential condensate retention issues.