What Is a Self-Locking Nut?

A self-locking nut is a nut with a function or mechanism to prevent loosening.

It is also commonly referred to as a lock nut. Tightened nuts can loosen due to vibration, impact, thermal expansion, and other factors. Therefore, there are various methods to prevent loosening of screws.

For example, there are double nuts in which two nuts are stacked on top of each other, spring washers or toothed washers are inserted between the nut and the object to be tightened, and adhesives are applied to the threaded part. A self-locking nut, on the other hand, can prevent loosening with only one part, and its advantage is that it is easy to install.

Uses of Self-Locking Nuts

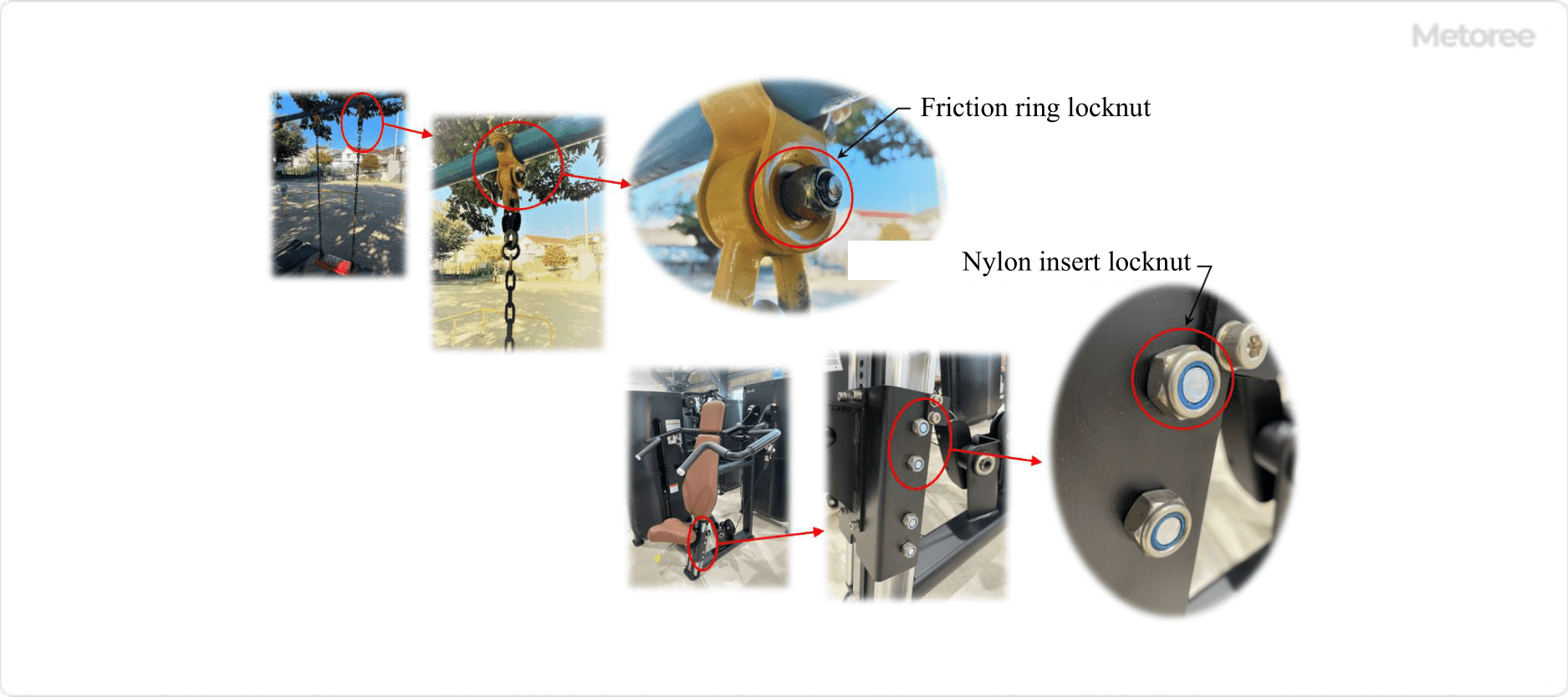

Figure 1. Examples of the use of anti-loosening nut

Self-locking nuts are used in locations where loosening of bolts and nuts can cause damage or accidents. Examples include automobiles, aircraft, railroad cars, bridges, and buildings. Most of these products have the potential for damage or accidents due to loosening bolts and nuts that could cause them to fall off.

Other applications include swing chain suspension shafts at playgrounds in parks and frame fixation parts of training machines in gymnasiums.

Principle of Self-Locking Nuts

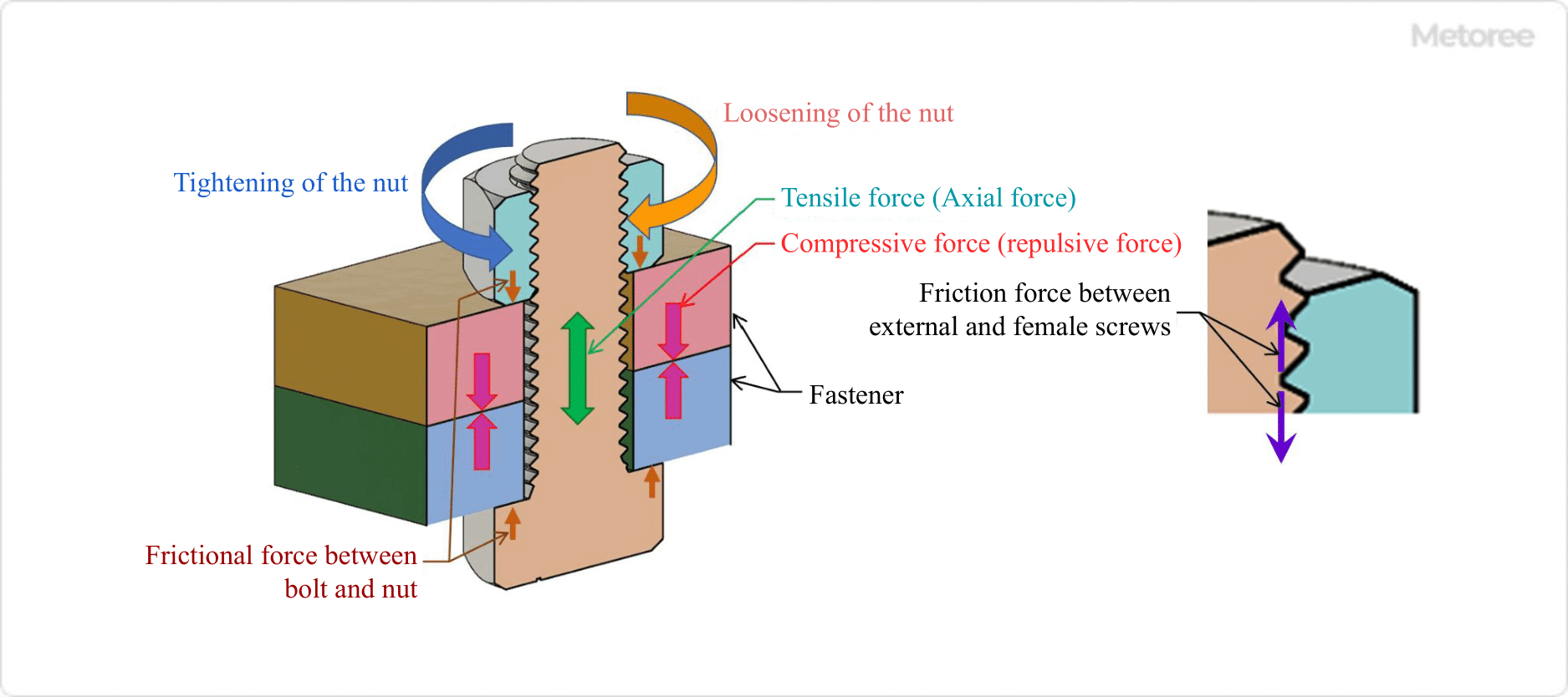

Figure 2. Principle of tightening and loosening with screws

When a bolt or nut is tightened on a fastened object, the object is subjected to a compressive force (pinching force), while the bolt shaft is subjected to a tensile force that is repelled by the object. This tensile force generates a frictional force between the bolt/nut’s seating surface (the surface in contact with the object to be fastened) and the object to be fastened, and the screw is fixed.

In this state, the following three frictional forces work and interact with each other.

- The frictional force between the male screw and the female screw.

- The frictional force between the fastened object.

- The frictional force between the bolt/nut seat and the object to be fastened.

When this frictional force is lost for some reason, it is called “screw loosening.” An example is shown below.

- The frictional force decreases due to distortion or indentation of the bolt/nut seating surface or the surface of the fastened object in contact with the seating surface.

- Vibration reduces the axial force, which in turn reduces the frictional force between the male and female threads.

- The frictional force is lowered due to the penetration of oil or other lubricating substances between the male thread and the female thread.

Types of Self-Locking Nuts

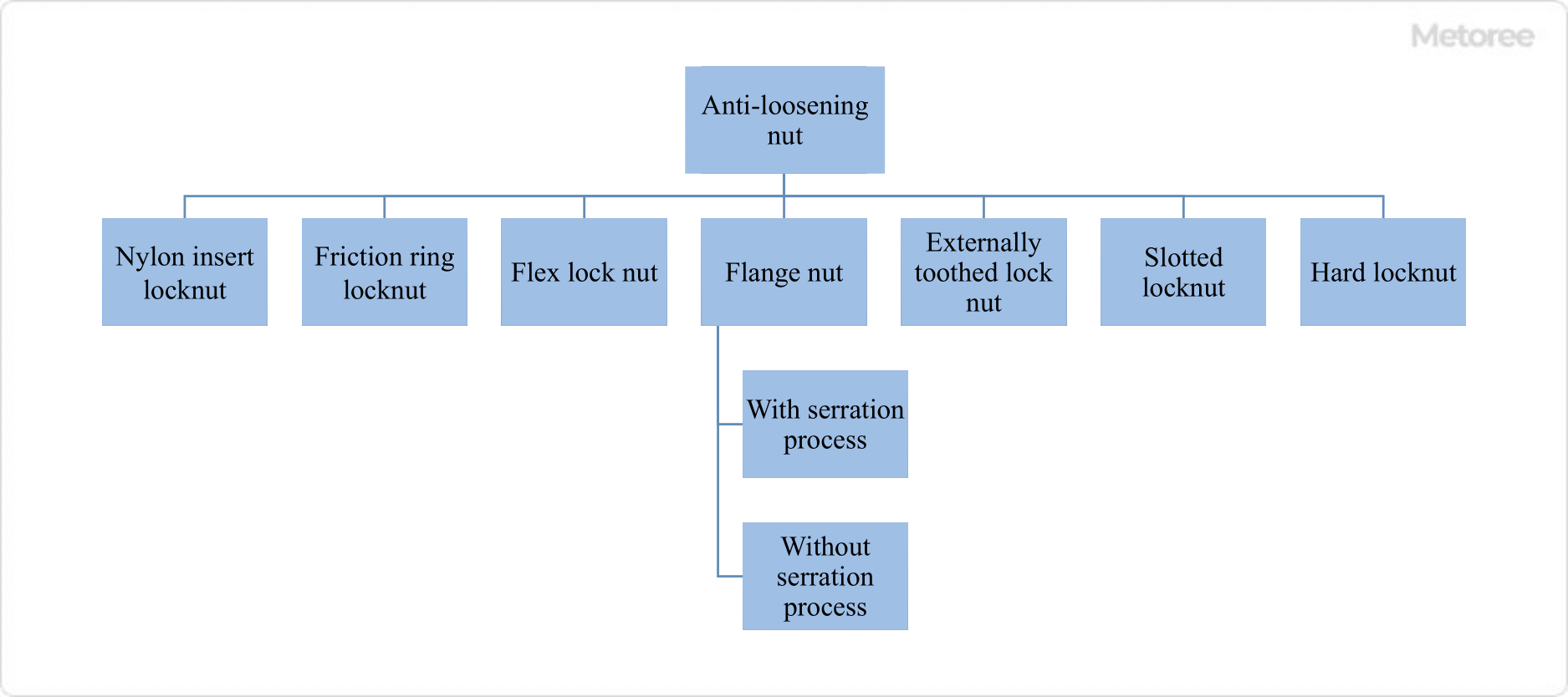

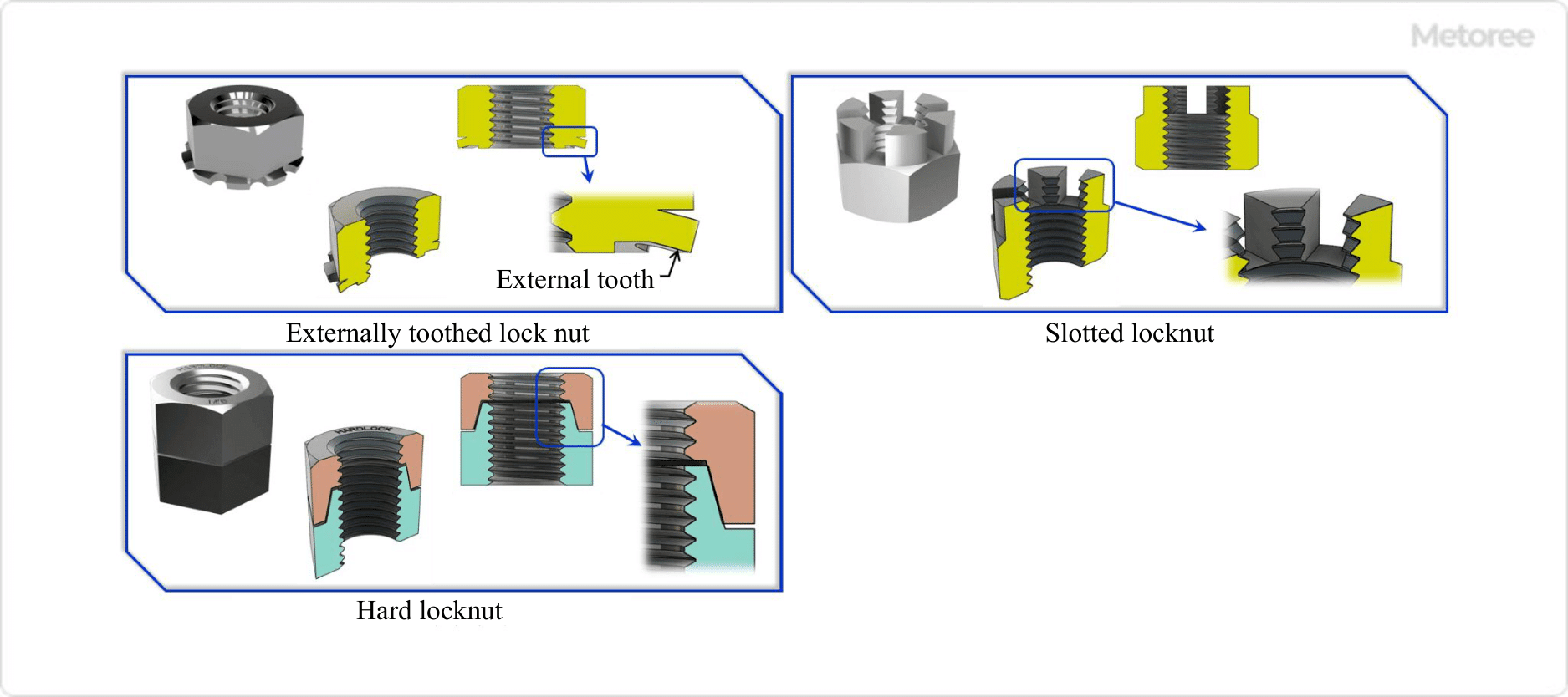

Figure 3. Types of anti-loosening nuts

There are several types of self-locking nuts, depending on their shape and self-locking method. Since each has its own characteristics and suitable application, it is often the case that they are used differently depending on the cause of loosening.

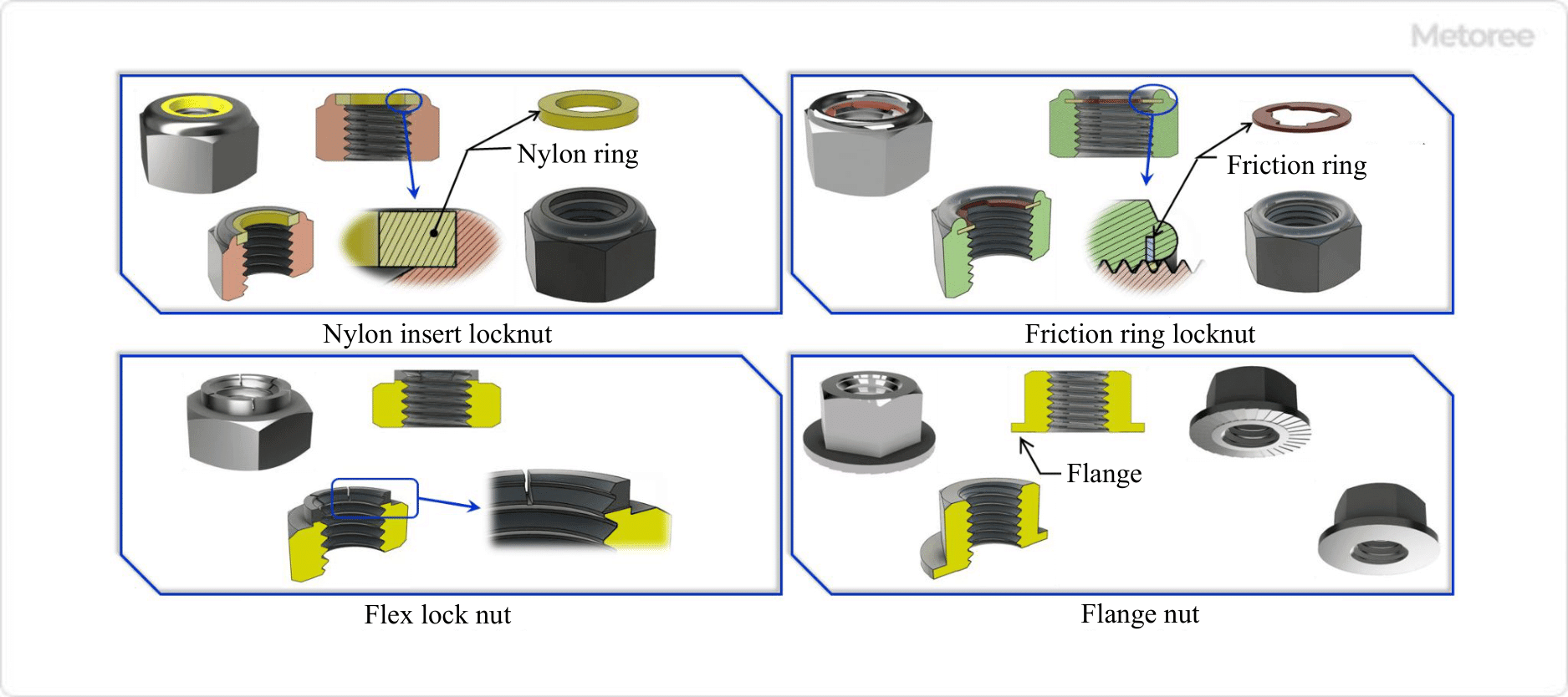

Figure 4. Types and shapes of anti-loosening nuts (1)

Figure 5. Types and shapes of anti-loosening nuts (2)

Other Information About Self-Locking Nuts

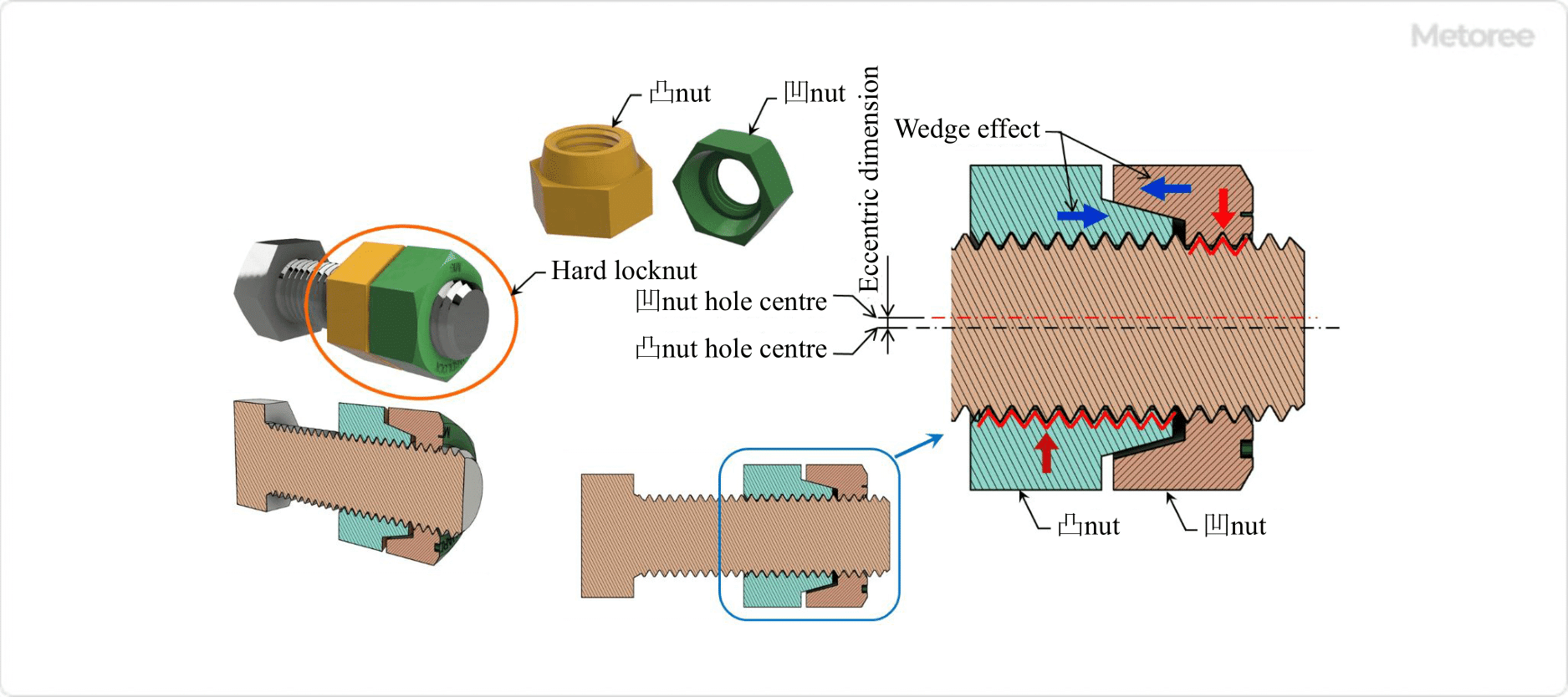

1. Application of the Wedge Principle

Figure 6. Principle of the wedge

Self-locking nuts apply the wedge principle to prevent “screw loosening” as described above.

By eccentrically aligning the center axes of the two nut holes and tightening the nuts with a conical concave-convex fit between them, a large frictional force is generated on the conical surfaces of the nuts to prevent loosening of the screw. An example of a product is the “hard lock nut,” which can be used repeatedly.

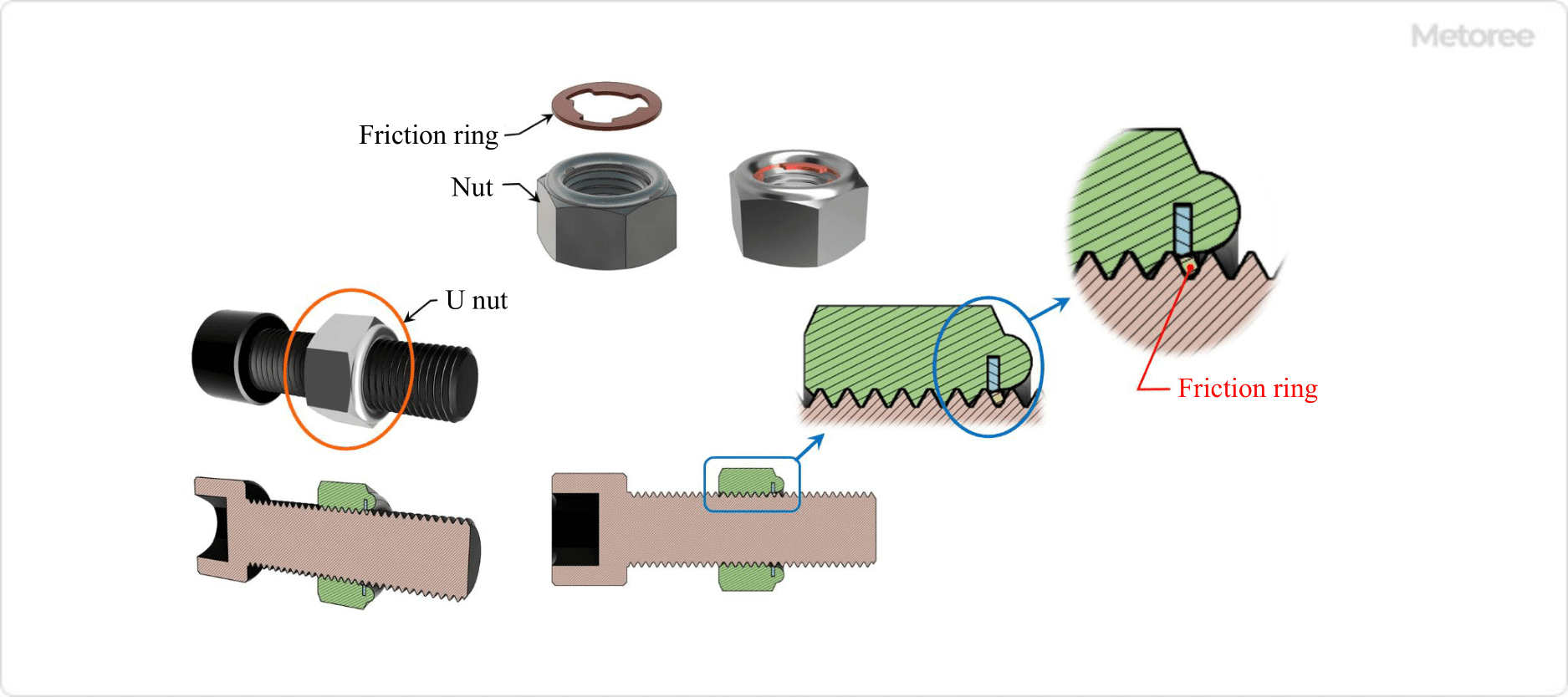

2. Increased Frictional Force With Screw Threads

Figure 7. Principle of friction ring locknut

A metallic spring-effect ring is attached to the top surface of the nut and contacts the male thread of the bolt to increase frictional force, thereby creating a self-locking nuts effect. Generally, this is a “friction ring locknut,” and product examples are called “U nuts.”

Friction ring locknuts have excellent heat and earthquake resistance. An example of such a product is the ‘nylon insert lock nut. Other examples include the “flange nut,” which has a higher frictional force on the seating surface to prevent loosening, and the “grooved nut,” which is secured by a pin that passes through the nut and bolt to prevent loosening.