What Is a Rare Earth Metal?

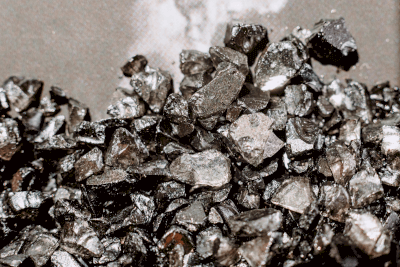

The definition of a Rare Earth Metal is not clear, but it is a general term for metals that are scarce in the earth’s crust, difficult to extract for economic or technological reasons, or important to secure in a stable manner in industry.

The major Rare Earth metal-producing countries are Australia, China, Russia, and South Africa, and the global competition for rare metals is heating up.

Other metals that are produced in large quantities and used in various materials, such as iron, copper, and aluminum, are called base metals. Eight elements, including gold, silver, platinum, and palladium, are rare, corrosion resistant, and are called precious metals.

Uses of Rare Earth Metals

Rare earth metals are employed to enhance the corrosion resistance, melting point, and strength of materials due to their unique properties such as corrosion resistance, heat resistance, ferromagnetism, and superconductivity.

Lithium, cobalt, and nickel are used as cathode materials in batteries. Neodymium and dysprosium are used as powerful permanent magnets in PC HDDs, electric vehicle drive motors, and home appliances. Tantalum is used in capacitors for circuit boards inside electrical appliances, and tungsten is used in tools due to its hardness.

Indium is an essential element in making transparent electrodes for LCD panels. Niobium is used in superconducting magnets for linear motor cars, where extremely low temperatures are involved, and in alloys for engine nozzles in rocket satellites, which are subjected to very high temperatures. Gallium has led to improvements in energy conversion efficiency through the development of LEDs and power transistors.

Rare earth metals have a variety of applications but are rarely used alone. They are usually added to base metals and alloyed to achieve their functions.

Characteristics of Rare Earth Metals

Rare earth metals have the common characteristics of strengthening structures and adding new functions to materials by adding them to base metals.

Tantalum is a metal with high dielectric constant, excellent corrosion and acid resistance, and good workability, and is therefore used in capacitors inside electrical appliances.

Tungsten has excellent properties such as hardness and heat resistance at high temperatures, so it is processed into metal parts for tools that are expected to be used in harsh environments.

Although tungsten is an extremely useful Rare Earth Metal, it also poses the problem of frequent imbalances between supply and demand. When the supply/demand balance is disrupted, prices fluctuate wildly and have a significant impact on industrial activities.

Like petroleum, rare earth metals are also resources that are at risk of depletion; by 2050, many types of metals will have exhausted their existing reserves, and there are concerns that demand for some rare metals, such as indium, will far exceed the amount of reserves available.

In recent years, to address this supply/demand balance, recycling technologies have been developed to extract rare earth metals from the urban mining resources accumulated above ground.

Rare Earth Metals Recycling Technology

There are growing expectations for technologies to extract rare earth metals from urban mines. Advantages of recycling include the following:

- The extractable amount is clear, and there is no need for exploration.

- Rare earth metals are generally of higher quality than natural ores because of their intensive use in processing.

- There is significant potential for resource and energy conservation in terms of mining and refining.

Extraction of metals from urban mines generally involves the process of “dismantling and component separation” → “extraction of target materials and materialization”.

Urban mine development has great potential and is becoming an important issue for Japan, a country with limited natural resources. Efforts are being developed to recover used cell phones and small electronic devices and extract rare earth metals from them. However, the following challenges persist:

Dispersion

Cell phones and other billion small electronic devices are dispersed throughout the hands of individual consumers, making it difficult to put them in the recycling process unless they are collected efficiently.

Waste

Even if rare earth metals are contained in small electronic devices in high purity, a large part of them are other materials such as plastics, and effective use of materials other than rare earth metals must be considered.

Cost

One cell phone contains only about 75 cents of rare earth metals, and we must develop a technology (mechanism) to separate, extract, and recover rare earth metals at a lower cost than this.