What Is an Abrasive Compound?

An abrasive compound is a product used to sharpen or polish material surfaces, typically available in powder or granular form, but also used in a broader sense when mixed with water or oil.

In the past, abrasives were made by grinding natural materials like garnet. Nowadays, most abrasives are artificially manufactured, with materials such as granulated alumina, silicon carbide, diamond, and others being used depending on the material being processed and the intended purpose.

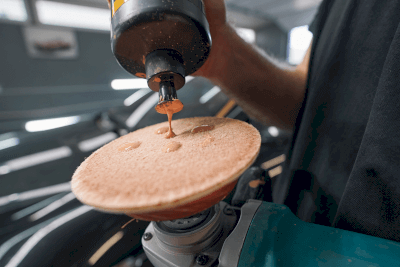

The abrasive compound is rarely used alone. For greater convenience, they are often hardened with a bonding agent and used as artificial grinding stones, or adhered to paper or cloth and used as abrasive sheets.

Uses of Abrasive Compounds

Abrasive compounds are used to polish metal and plastic surfaces to improve dimensional accuracy and luster.

Abrasive compounds are mainly defined by particle size (grain size). In general, abrasives with larger grain sizes are used first, as they offer superior processing speed, and then smaller ones are used according to the required accuracy.

While abrasive compounds are commonly used on flat surfaces, they can also be applied to process curved surfaces and inside diameters by affixing a brush, etc., coated with abrasive compounds, to a rotating body.

Principle of Abrasive Compounds

Abrasive compounds are processed to reduce the surface irregularities by gradually scraping the material surface with hard fine particles.

There are two types of abrasive processes: the fixed abrasive method, which uses a tool with abrasive compound particles fixed with a bonding agent, and the loose abrasive method, which uses abrasive particles in a discrete state.

In the fixed abrasive method, the abrasive grains are fixed and cut into the workpiece, resulting in superior polishing time and processing efficiency.

On the other hand, the loose-grain method allows the abrasive grains to tendon the workpiece, resulting in a more precise machined surface.

Rough grinding is used to ensure high efficiency, dimensional accuracy, and shape accuracy, and uses abrasives with relatively low particle size and high hardness. Fine grinding is a process used to reduce surface roughness and uses high particle size and soft elastic abrasives. Rough polishing is used to shape the surface to be polished, and fine polishing is used to polish and mirror the surface.

The appropriate abrasive compound material and particle size should be selected depending on the material of the surface to be polished and the degree to which the surface is to be polished.

Characteristics of Abrasive Compounds

There are several types of abrasive compounds, each of which has different hardness and reactivity.

The most commonly used abrasive compound is corundum crystal alumina, which is used in combination with zirconia or titanium to provide hardness and toughness and is mainly used for polishing iron and stainless steel.

Abrasives made from silicon carbide are harder and tougher than alumina and less expensive than diamond. As a result, they are widely used for polishing metals and non-metals. However, they are not suitable for polishing iron and stainless steel.

Like silicon carbides, they react with iron and nickel and lose their performance, so their use is limited to specific applications.