What Is a Heat-Treating Furnace?

A heat-treating furnace is used to enhance the structure and properties of metals through controlled heating and cooling processes. These furnaces play a critical role in various manufacturing sectors by altering the physical and sometimes chemical properties of materials to achieve desired engineering outcomes.

Uses of Heat-Treating Furnaces

Heat-treating furnaces are pivotal in industries ranging from food processing, where they are used for sterilization, to the automotive sector, supporting the production of highly rigid components. The versatility of heat-treating furnaces allows for their application in improving the durability, strength, and performance of metal parts.

Principle of Heat-Treating Furnaces

The core operations of heat-treating furnaces include quenching, tempering, normalizing, and plating of steel. These processes, facilitated by either incinerator or electric heating methods, hinge on precise temperature and time control to ensure uniform product quality. The distinction between heating methods lies in their fuel source and heating accuracy, with electric furnaces providing pinpoint heating capabilities.

Structure of Heat-Treating Furnaces

Heat treating involves a meticulous set of heating and cooling stages, with the equipment type varying based on the specific heat treatment process. Batch and continuous types represent the two primary categories of heat-treating furnaces, each designed to accommodate different production volumes and operational needs.

Types of Heat-Treating Furnaces

1. Forging Furnace

Materials such as steel bars are heated to an appropriate temperature to make them plastic before forging.

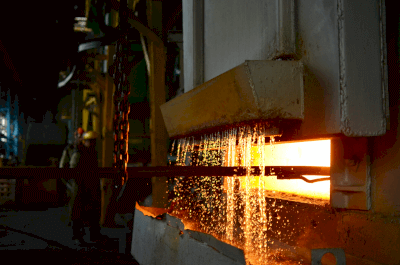

2. Rolling Furnace

Billets, slabs, and billets are heated to a plastic state and rolled into products such as steel shapes, bars, wire rods, and steel plates.

3. Standardizing Furnace

Quenching furnaces are used to improve the mechanical properties and machinability of steel by homogenizing the microstructure of steel that has become non-uniform during casting and forging.

4. Annealing Furnace

Removes internal stresses produced by cold working. Unlike quenching, the material is heated and then cooled slowly in the furnace.

5. Quenching Furnace

Hardens steel to make it wear-resistant. After heating, the steel is quenched in a water or oil bath.

6. Tempering Furnace

Tempering furnace toughens steel that has become brittle during quenching and remove residual stresses to prevent quench cracking. The quenched steel is heated to 700°C or lower and cooled in air.

7. Carburizing Furnace

Hardens the steel surface and imparts wear resistance. The steel is heated in a carburizing endothermic transformation gas for a certain period and then quenched to a temperature slightly higher than the austenite transformation temperature to prevent distortion.

8. Aluminum Heat-Treating Furnace

Aluminum heat treatment furnace removes distortions caused by machining and cooling shrinkage of castings and ensures proper mechanical properties by homogenizing the microstructure.