What Are Hanging Brackets?

Hanging brackets, including lugs or lifting lugs, are devices designed for lifting or suspending heavy objects safely and efficiently. These brackets play a vital role in enhancing work efficiency, reducing labor time, and significantly improving job site safety by securely holding objects and preventing falls.

It’s crucial to adhere to the load limits specified for hanging brackets to avoid overburdening them, which could lead to accidents.

Applications of Hanging Brackets

Hnging brackets facilitate the movement and installation of objects across various sectors.

- Lighting – Utilized to mount lighting fixtures on ceilings or walls, ensuring optimal positioning.

- Construction – Integral for moving or installing building materials and structures on construction sites, often used with cranes and other machinery to handle steel frames and construction materials.

- Transportation – Critical for the efficient loading and unloading of cargo in transportation, attached to containers and pallets for easy handling at ports and distribution centers.

- Warehousing – Facilitates the movement and storage of large items or machine parts in warehouses, enhancing work efficiency and inventory management.

Principle of Hanging Brackets

Hanging brackets leverage mechanical engineering principles to lift or suspend objects. Typically constructed from steel or stainless steel, these brackets are chosen for their durability and, in certain environments like the food industry, for their resistance to rust.

Types of Hanging Brackets

Diverse in shape and design, hanging brackets are selected based on specific needs.

- Hooks – Common for lifting, hooks attach to cargo and are connected to chains for transportation.

- Shackles – U-shaped devices secured with a bolt or pin, used for their strength in supporting heavy loads with cranes and winches.

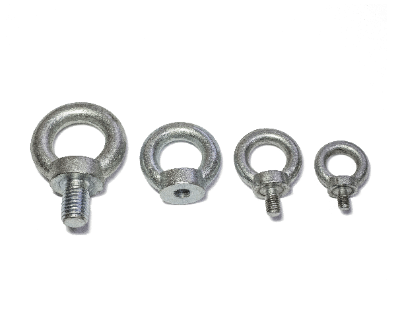

- Eyebolts – Ring-shaped fittings with a screw at one end, providing suspension points for objects, ideal for construction and factory use.

Selecting Hanging Brackets

Selection should consider the weight and center of gravity of the equipment to ensure safety. The installation angle and the actual load must be factored in to prevent accidents, emphasizing the importance of selecting brackets that match the strength requirements and hanging posture of the equipment.