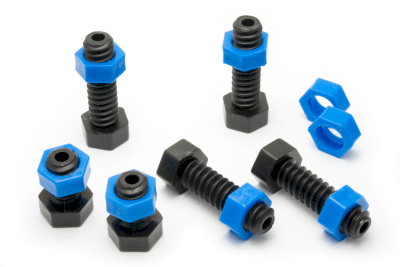

What Is a Plastic Nut?

A plastic nut is molded from resin, distinguishing it from traditional metal nuts.

Nuts are components that, used alongside bolts and screws, fasten or assemble machinery. They have a threaded center hole; bolts have male threads, whereas nuts have female threads.

Being lightweight, plastic nuts are favored in applications where reducing weight or mitigating vibration is crucial. They also serve as excellent electrical insulators, making them ideal for electrical insulation needs.

However, resin tends to be more brittle and less durable than metal, necessitating caution when using plastic nuts in high forces applications.

Uses of Plastic Nuts

Plastic nuts find use in various applications, leveraging their unique properties. Below are some examples:

1. Electronic Equipment

In electronic equipment and electrical wiring systems, plastic nuts provide superior insulation compared to metal nuts, securing electronic components and wiring effectively. Their application is crucial in preventing short-circuit failures in computers and household appliances, where electrical insulation is paramount.

2. Furniture

They are employed in assembling household utensils and furniture, favored for their lightweight yet sufficient strength for fixing. Applications include furniture legs, handles, and small assembly parts.

3. Outdoor Lighting

The corrosion resistance of plastic nuts benefits the assembly of outdoor lighting and components, offering a viable alternative to metal nuts prone to corrosion.

4. Plastic Products

When assembling plastic parts, using metal nuts may cause damage. Plastic nuts, less likely to harm plastic components, are preferred for assembling plastic enclosures and covers.

Characteristics of Plastic Nuts

Plastic nuts, made from plastic materials, are utilized for fastening along with bolts and screws. Key characteristics include electrical insulation and lightweight. Their insulation property is particularly valued in electronic device assembly. Additionally, their flexibility and vibration absorption capacity surpasses that of metal nuts.

Types of Plastic Nuts

Various plastic materials are used to manufacture plastic nuts, each with distinct advantages:

1. Polypropylene Nut

Polypropylene, known for its lightweight, chemical resistance, and low density, is suited for lightweight constructions and withstands outdoor and humid environments.

2. Nylon Nut

Nylon nuts, celebrated for their durability and chemical and vibration resistance, are versatile, fitting for insulation-required and lightweight assemblies.

3. Polycarbonate Nut

Polycarbonate, a resin known for its high transparency, impact, and heat resistance, is often chosen for transparent parts and lighting applications.

4. Polyethylene Nut

Polyethylene nuts are recognized for their durability, chemical resistance, and resilience against chemical corrosion and decay, making them suitable for outdoor use or environments with chemical exposure.

5. Polyvinyl Chloride Nut

These nuts offer excellent insulation and chemical resistance, are easy to process, and are cost-effective. However, their strength may be compromised in high-temperature and high-load conditions.