What Is a High Voltage Transformer?

A high voltage transformer is a transformer that inputs high voltage as a primary voltage and outputs a stepped-down or stepped-up secondary voltage.

A high voltage transformer is a transformer that inputs high voltage as a primary voltage and outputs a stepped-down or stepped-up secondary voltage.

A transformer is a device that converts the voltage of an input current to another voltage for output. Converting to a lower voltage than the input voltage is called step-down, and conversely, converting to a higher voltage is called step-up. There are three types of power supply voltage standards: low voltage, high voltage, and special high voltage.

Uses of High Voltage Transformers

High voltage transformers are generally used to supply power to large facilities with high power consumption, such as factories, hospitals, and commercial facilities.

Electricity generated at power plants is very high voltage, tens of thousands of volts. This power cannot be used if it is transmitted directly to users. However, from the standpoint of transmission efficiency, the power is transmitted at high voltage and low current in the vicinity of the supplier, and then stepped down to a voltage that can be used by a high-voltage transformer.

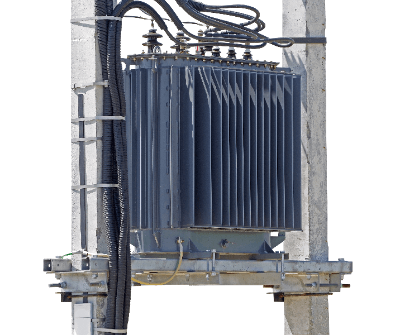

High voltage transformers are generally built into high voltage receiving facilities called cubicles and placed on rooftops.

Principle of High Voltage Transformers

A transformer consists of two coils. The two coils are electrically separated but magnetically connected by an iron core.

The coil on the input side is the primary coil and the output side is the secondary coil. When a current flows through the primary coil, a magnetic flux is generated based on Ampere’s law. This magnetic flux is transmitted through the iron core to the secondary coil, and based on Faraday’s law of electromagnetic induction, a voltage corresponding to the number of turns of the coil is generated. Thus, by using the coil and iron core, it is possible to convert the voltage between the input and output power sources.

Other Information on High Voltage Transformers

1. Cooling System of High Voltage Transformer

Since heat is generated inside the transformer due to power loss, a cooling system is introduced. There are two types of cooling methods: the “oil-filled method” in which the windings are cooled with insulating oil, and the “molded method” in which no oil is used.

Since high voltage transformers are used in facilities where strict disaster prevention measures are required, the “molded type” is often adopted because of its low fire risk. In the case of oil-filled transformers, Class 3 petroleum is used for the insulating oil. Note that as the capacity of the high voltage transformer increases and the amount of oil exceeds 400 L, the oil by itself is considered a hazardous material.

Also, as the capacity increases, it becomes more difficult to use self-cooling transformers, so the forced circulation type is used.

2. Price of High Voltage Transformers

High voltage transformers are relatively inexpensive among industrial equipment because of their simple mechanism. For a transformer with a typical temporary voltage of 6,600V/3,300V and a secondary voltage of 400V/200V/105V, catalog products are available from various heavy electric appliance companies.

Catalog products are considered having an upper limit of around 2,000 kVA, and anything above that is made-to-order. The average price of an oil-filled, self-cooling transformer is several hundred thousand yen for a transformer of several tens of kVA, and several million to 20 million yen for a transformer of 2,000 kVA (as of 2021). Molded systems are more expensive.

The above prices are for general step-down transformers, but those with special specifications are made-to-order, so consultation with heavy electric machinery companies is required for pricing.

3.High Voltage Transformer Capacity

The capacity of a high voltage transformer is determined by the allowable current value of the windings and the capacity of the magnetic iron core. If a current exceeding the allowable value flows through the windings, the transformer is protected by an overcurrent relay to prevent burnout.

The capacity of a three-phase motor, for example, is measured in kilowatts (kW), whereas the capacity of a high voltage Transformer is measured in kilovolts (kVA). Catalog products of single-phase, three-wire High Voltage Transformers have an upper limit around 300 kVA, while three-phase 400 V/200 V transformers have an upper limit of 2,000 kVA.

In the case of a cubicle type, the upper limit for commercial products is around 750 kVA due to the size of the enclosure and cooling capacity.

4. Power Factor of High Voltage Transformers

It is important to note that the amount of work applied to a high voltage transformer varies depending on the power factor of the load. The further the power factor is from 1, the less work can be applied. By keeping the power factor of the secondary side of the high voltage Transformer at 1, the high voltage transformer can be used to its capacity without waste.

Since industrial machinery has many motors, the power factor often swings in the lagging direction. As a general measure, a power capacitor is connected in parallel with the load to compensate.

High voltage transformers are designed for maximum efficiency at around 60% load. Therefore, it is important to select a capacitor with a generous margin so that the normally used capacity will be around 60%.