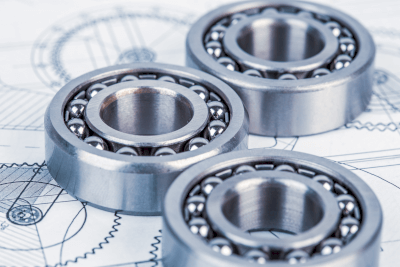

- What Is an Angular Contact Ball Bearing?

An angular contact ball bearing has contact angles between the balls and the inner and outer rings.

Angular contact means that the line connecting the contact points between the inner ring and the balls and the contact points between the balls and the outer ring is not perpendicular to the axis of rotation (do not intersect at 90°). In a standard radial ball bearing, the line connecting the two points of contact between the inner and outer rings and the balls is perpendicular to the axis of rotation of the bearing.

Angular means angle and the contact angle permits radial loads (loads perpendicular to the axis) and axial loads (loads horizontal to the axis) in one direction up to a certain amount.

Uses of Angular Contact Ball Bearings

Angular contact ball bearings are used in hydraulic pumps, vertical pumps, compressors, elevator hoisting machines, belt conveyors, etc., because they can tolerate a certain amount of radial and axial loads in one direction.

Connecting two or more of them can support axial loads in both directions or even more axial loads in one direction. When two or more bearings are assembled, it is essential to determine the orientation of each bearing after carefully checking the load to be supported in each direction.

Principles of Angular Contact Ball Bearings

There are several types of bearings, which can be divided into rolling bearings and plain bearings. Rolling bearings are often used in cars and industrial machinery. Rolling bearings are mainly composed of the following three elements:

- Raceways (inner and outer rings in which balls and rollers roll)

- Rolling elements (balls or rollers that roll between the inner and outer rings)

- Retainer (the part that prevents rolling elements from colliding with each other or falling out of the raceway)

In addition, angular contact ball bearings have contact angles between the raceways and rolling elements. The larger this angle, the larger the allowable axial load. However, it is vital to select the proper angle, as this may require a reduction in rotation speed.

Other Information on Angular Contact Ball Bearings

- Contact Angle of Angular Contact Ball Bearings

The standard contact angles of angular contact ball bearings are 15°, 30°, and 40°, which are indicated by the symbols C, A, and B, respectively. The allowable axial load and allowable rotational speed vary depending on the size of the contact angle.

When used at high rotational speeds, a small contact angle is often selected, and when the axial load is large, a large contact angle is often selected. The contact angle also makes it possible to combine two angular contact ball bearings and apply a pressurizing force, improving rotational accuracy and rigidity.

- Pressurizing Angular Contact Ball Bearings

The amount of pressurization is determined by combining bearings in opposite directions and controlling the internal clearance. There are two types of combinations for pressurization: frontal and backward varieties, represented by the symbols “DF” and “DB.” In addition, there is a parallel combination “DT” with opposing combinations.

Pressures are classified as “fine,” “light,” “medium,” and “heavy” and should be selected according to the conditions of use. Each pressurization amount is determined by the bearing size and is described in the technical data of each manufacturer. When applying pressure, care should also be taken not to increase the pressure too much, for example, by slightly changing the dimensional tolerances of the parts to be installed.

If the pressurization is too large, rigidity will increase, but resistance to rotation will increase, which may cause problems such as increased heat generation or bearing deformation. There are several ways to apply pressure, but the constant-pressure and fixed-position methods are generally used.

- Constant pressure method

- This method uses a spring or other means to apply a constant force to the bearing, and the pressurization can be maintained constant even if the bearing wears out. However, the disadvantages are that the structure is complicated, and the calculation of the spring force is necessary.

- Fixed-position method

- A spacer is placed between the two bearings. The amount of pressurization is adjusted by controlling the thickness of the spacer. Although the amount of pressure applied changes as the bearings wear, this method is often used because of its simple structure.

Although pressurization is indispensable for the accurate use of angular contact ball bearings, it must be considered following the operating conditions when designing the bearings. Mounting parts must also be finished with high precision.