What Is a Rolled Ball Screw?

A ball screw is a component that converts a motor’s rotational power into linear or linear power into rotational power. It consists of a threaded part and a moving part. It is mainly used for linear motion.

Among ball screws, there are two types: rolled ball screws and ground ball screws. Ground ball screws offer higher precision. In addition, ball screws are divided into two types, one for positioning and the other for conveyance, each of which is determined by its accuracy.

Uses of Rolled Ball Screws

Ball screws are classified into two types according to their accuracy, of which there are many more accuracy grades. Grades C0 to C5 are used for positioning. For conveyance applications, grades C7 and C10 are used.

Ball screws are mainly used in industrial robots, machine tools for positioning and conveyance, and semiconductor manufacturing equipment. They are often used to convert the rotational motion of a motor into linear motion. The load itself is applied from the axial direction only. Therefore, a guide is required.

Principles of Rolled Ball Screws

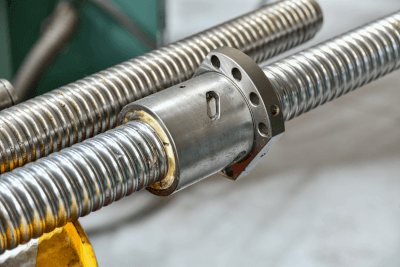

A ball screw consists of a screw shaft, nut, and ball. The ball is placed between the screw shaft and the nut and rolls lightly. The action is such that the balls circulate endlessly. The most common type is the return plate type. The ball that has come to an end passes through the plate and returns to the tip again to perform a rolling motion.

The following is a description of the manufacturing process of rolled ball screws. A round bar is used as the steel material. The steel material is a round bar threaded by a tool called a rolling die while being rotated. The threading is done by combining two rolling dies.

In addition to rolled ball screws, there are ground ball screws. In a ground ball screw, the thread grooves are created by grinding cylindrical steel. Therefore, they can be manufactured with higher precision than rolled ball screws. The disadvantage is that it is more expensive. Axial clearance is also reduced.