What Is a Single-Axis Positioning Stage?

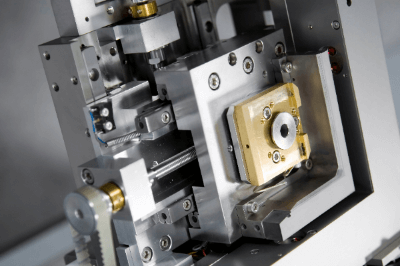

A single-axis positioning stage is a unit that can be positioned in one specific direction.

This type of stage can move only in a single direction, such as horizontally (X-axis), vertically (Z-axis), or in rotation, angle, or goniometric positions, depending on the model.

When using this unit, consider the direction of movement and positioning accuracy based on the application.

As it is a single-axis positioning stage, a 2-axis stage is recommended for movements in both X- and Y-directions.

If a unit equipped with a micrometer or a similar device is used, precision in movements can be achieved.

Uses of Single-Axis Positioning Stages

Single-axis positioning stages are utilized for positioning, adjustment, and other movable adjustments in inspection equipment, devices, and parts requiring precise movements.

These stages vary in accuracy, so it is important to select the ones that best suit the intended purpose and usage conditions.

Examples of single-axis positioning stages include:

- Positioning equipment for product inspection.

- Stroke adjustment in equipment positioning (part assembly).

- Adjustment of product assembly jigs for model changes.

- Transportation and positioning of FA equipment.

Principles of Single-Axis Positioning Stages

A single-axis stage consists of three main mechanisms: guide, feed, and clamp.

There are three types of guide mechanisms:

- Dovetail Groove: a mechanism that slides between male and female dovetail grooves.

- Crossed Rollers: a mechanism in which rollers are arranged on V-groove rails and move across the V-groove.

- Linear Ball: a mechanism where balls are arranged in grooves and move by sliding within them.

Each feed mechanism also has distinct characteristics:

- Rack and Pinion: this mechanism is less precise but essential for speed and not suitable for precise positioning.

- Feed Screw: used for fine adjustments (around 0.5 mm), not ideal for long strokes.

- Micrometer: ideal for precision adjustments (in 0.01 mm increments), not suitable for long strokes.