What Is a Grease Pump?

A grease pump is a device used to fill sliding parts of various machines with grease for smooth operation.

Grease can be filled by engaging a grease nipple attached to a joint or rotating part and pumping grease. In addition to manual pumping, electric and air-driven pumps are also available to shorten the time required for maintenance.

There is also a type that periodically fills a predetermined area with a fixed amount of grease, which is sometimes referred to as an “auto-greaser.”

Uses of Grease Pumps

Grease pumps are used for parts that repeatedly slide during machine operation. The purpose is to prevent metal parts from coming into direct contact with each other, thus preventing wear of the sliding parts.

In particular, construction machinery such as dump trucks and wheel loaders that travel on unpaved roads such as sandy soil and construction sites, as well as agricultural machinery such as tractors, are used for long periods of time in an environment where sand and dust are flying around. For this reason, grease pumps must be used to fill the machinery with new grease frequently.

In addition, air-driven ones are sometimes used in factories that service such machinery to improve work efficiency. Grease pumps range from small to large, and can be used in different ways depending on where the work is to be done.

Smaller pumps are lighter and can be used to fill grease in tight and difficult-to-work-in areas, but require frequent replenishment of grease. It is not uncommon for different types of grease to be used at different sites, and it is not uncommon to have a grease pump for each type of grease.

Principle of Grease Pumps

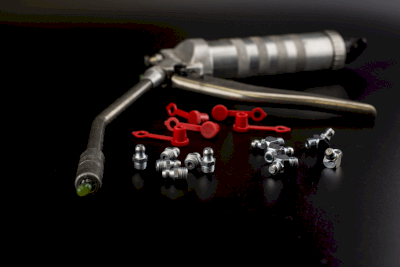

Grease pumps are filled with grease via grease nipples, and the shape of the nipple and nozzle must match. If the shapes do not match, grease pushed out at high pressure will not enter the grease nipple and will be blown out through the gap.

In addition to the multiple types of nipples, there are also various types of nozzles. The straight type, which extends straight from the Grease Pump, provides a stable grease fill.

If the grease nipple is located in an intricate area inside, there are hose types that bend freely, so it is important to use different types depending on the area of use.

Types of Grease Pumps

A grease pump is a device for pumping grease. There are two types of grease pumps: manual and electric/air-driven.

1. Manual Type

The manual type has the advantage of being relatively small and portable. However, it has the disadvantages of requiring frequent replacement of grease cartridges and not being suitable for work in a confined space due to the pumping being done by hand.

Since it is inexpensive and does not require a power source, the manual type is basically chosen if the frequency and filling points are not particularly large.

2. Electric/Pneumatic Type

In contrast, the electric/pneumatic type pumps grease by simply operating the trigger, allowing greasing in a small space as long as the tip of the gun can fit. This reduces the burden on the operator, but has the disadvantages of poor portability and the need to secure a power source.

Air-driven ones are sometimes used in factories that maintain construction machinery and other equipment to improve work efficiency. In addition, air (air bubbles) often get trapped in the grease path when replacing grease cans with electric or air-driven ones.

Since it takes some time to remove air bubbles, it is necessary to fill the grease pump with grease to some extent to prevent air bubbles from being trapped during the grease replacement process.

Other Information on Grease Pumps

How to the Replenish Grease

Grease pumps are also classified by grease replenishment. The direct-fill type, in which grease is directly replenished into the grease pump, offers a variety of grease pump shapes to choose from, while the other type requires replenishing grease into the grease pump as it is.

If you want to replenish grease easily, use the one for cartridges, which can be replenished with cartridge grease by means of the mounting screw. There are both direct-in and cartridge types, but the shape is made to fit the cartridge grease.