What Is a Coriolis Flowmeter?

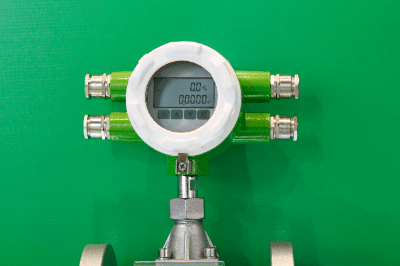

A Coriolis flowmeter is a flowmeter that utilizes the Coriolis force.

It is one of the few flowmeters that can measure mass flow and is frequently used in pharmaceutical and food manufacturing processes where mass flow measurement is required.

Most other flowmeters can only measure volumetric flow rate, and to obtain mass flow rate from volumetric flow rate, conversion must be performed using a pressure gauge, thermometer, density meter, etc. Coriolis flowmeters, on the other hand, can only measure volumetric flow rate. A Coriolis flowmeter, however, can provide mass flow measurement results with high accuracy by itself.

Uses of Coriolis Flowmeter

Coriolis flowmeter is mainly used to measure mass flow. Since volumetric flow rates are affected by pressure and temperature, mass flow measurement is used in situations where errors due to these effects cannot be tolerated. Typical examples of applications in a wide range of industries are as follows:

1. Petrochemical Industry

They are used to measure the mass flow rate of raw materials and products during the production of petroleum and chemicals. Where fluid temperatures change significantly before and after product transactions, such as in the transportation of petroleum products. When the properties of a product vary greatly depending on its origin, such as liquefied natural gas (LNG) or liquefied petroleum gas (LPG).

2. Food Industry

They are used to measure the flow rate of liquid or viscous materials in the food production process. For example, it is used to measure the flow rate of chocolate or molasses.

3. Paper Industry

They are used to measure the flow rate of liquids in the papermaking process. It is also used to adjust the dosage and mixing ratios of various chemical liquids.

4. Medical Industry

Used to measure the flow rate of chemicals used in medical applications.

5. Fire Fighting

They are used to measure the flow of water in firefighting hoses and water discharge pipes.

In addition to these applications, Coriolis flowmeters are used in a variety of other industrial fields, including the aerospace, automotive, energy, and water treatment industries.

Principle of Coriolis Flowmeters

A Coriolis flowmeter uses the Coriolis force to measure mass flow, volume flow, density, and temperature with high accuracy. Coriolis force is the apparent force that appears when an object is in motion in a rotating coordinate system.

An oscillator is placed inside a U-shaped tube and fluid is allowed to pass through the tube. The oscillator generates lateral vibrations related to the rotation of the tube due to the inertial force generated when the fluid strikes the oscillator. The mass flow rate can be obtained by measuring the phase difference in the torsional angle of the tube that the sensors installed at the inlet and outlet make to the vibration.

The flow tube oscillates at its own vibration frequency, and the density of the fluid can be obtained from the frequency that varies with the density of the internal fluid. A thermometer is installed inside the flowmeter, and this temperature information is used to compensate for the hardness of the flow tube, enabling highly accurate measurements.

Based on the measured information, it is possible to ≈ calculate volumetric flow rate continuously, concentration, specific gravity, etc. Since only the flow tube is in contact with the fluid and there are no moving parts, various types of fluids can be measured with high accuracy.

Other Information on Coriolis Flowmeters

Features of Coriolis Flowmeters

The Coriolis flowmeter has the following three main features:

1. Wide Viscosity Range

A Coriolis flowmeter has a viscosity range of up to 10,000 CP (honey, etc.), depending on the grade of the Coriolis flowmeter. Examples of flowmeters suitable for measuring highly viscous fluids are positive displacement flowmeters, ultrasonic flowmeters, and electromagnetic flowmeters. A Coriolis flowmeter may be advantageous for high viscosity fluids that are slurries (disadvantageous for positive displacement flowmeters and ultrasonic flowmeters) or non-conductive fluids (disadvantageous for electromagnetic flowmeters).

2. High Price

The price of a Coriolis flowmeter is several hundred hundred to several thousand dollars at minimum. This is due to the fact that the Coriolis flowmeter requires advanced technology for machining the pipe inside the device and for controlling the sensor that detects the phase difference of the torsional angle.

3. Large Pressure Drop

The tube inside the Coriolis flowmeter is designed to be thin, resulting in a large pressure drop. This is to increase the sensitivity of the sensor by increasing the flow velocity in the tube and strengthening the Coriolis force.