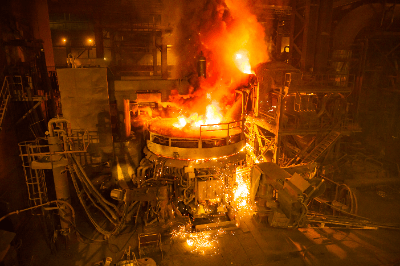

What Is an Electric Furnace?

An electric furnace is a testing equipment used to heat, melt, or burn test specimens such as metals, glass, ceramics, and semiconductor parts by heating a built-in heater (heating element) to a high temperature inside the chamber using electrical power.

They are used for various testing purposes, including the development of new materials, chemical material analysis, combustion testing, and heat resistance testing.

The maximum temperature that can be set inside an electric furnace varies depending on the product, but generally ranges from around 1,000°C to 3,000°C.

Uses of Electric Furnaces

In addition to electric furnaces with high-temperature settings, there are also vacuum furnaces that can create a near vacuum inside the chamber.

Another type is the rotary kiln, which automatically rotates the sample placed in the chamber to provide even heating. This kiln also includes a mechanism for the automatic loading and unloading of samples.

Various types of heating elements are used as heaters.

For example, iron nichrome and Kanthal wire are heating elements used for temperatures up to about 1300°C, while silicon carbide heating elements are used up to about 1500°C. Molybdenum disilicide can be used up to about 1800°C, and carbon (graphite) heaters are suitable for temperatures up to about 3000°C.

Principles of Electric Furnaces

The interior of an electric furnace comprises a heater and insulation material. Additionally, a control system is incorporated to set and maintain the temperature inside the chamber.

The control system operates as follows:

First, the desired temperature is set by operating switches while monitoring the control panel. Once the temperature is set, the electric furnace’s control microcomputer begins the temperature control process to reach and maintain the target temperature.

Some electric furnaces allow programming to set temperature A, maintain it for t1 hours, then set temperature B, maintain it for t2 hours, and so on.

To control the temperature inside the furnace, the control microcomputer periodically reads temperature data from the temperature sensor inside the chamber. If the current temperature is lower than the set temperature, the heater continues heating. If the current temperature exceeds the set temperature, the heater stops heating. This temperature control process is repeated to maintain the desired temperature.

Generally, the PID control method is used for precise temperature control inside the furnace.