What Is an Oldham Coupling?

Oldham couplings are mechanical devices designed to connect two misaligned shafts, transmitting rotation between them. Featuring a middle disc that compensates for misalignment between the connected shafts, these couplings are known for their ability to absorb parallel and angular misalignments while transmitting torque. Oldham couplings are favored for their affordability and versatility across various applications.

Applications of Oldham Couplings

Oldham couplings are commonly employed in machinery where precision alignment isn’t possible or cost-effective. Their primary applications include:

- Connecting drive shafts in machinery with moderate precision requirements.

- Accommodating misalignment in equipment such as conveyors and pumps.

- Facilitating quick disconnection and connection in systems needing regular maintenance or configuration changes.

How Oldham Couplings Work

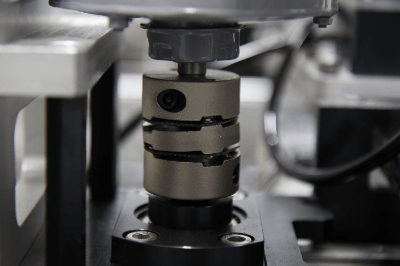

Comprising two hubs and a central disc, Oldham couplings allow the connected shafts to move independently. The disc, slotted to engage with grooves on each hub, slides to accommodate misalignment. This design ensures smooth torque transmission across misaligned shafts without significant efficiency loss or wear.

Key Features

Oldham couplings offer several benefits, including:

- Ability to handle parallel and angular misalignments.

- Easy assembly and maintenance due to simple three-part design.

- Variety of materials to suit different operating environments and torque requirements.

Choosing the Right Oldham Coupling

Selection criteria for Oldham couplings involve considering the application’s torque requirements, the degree of shaft misalignment, and environmental factors. Material choices for hubs and discs vary, with options like aluminum for lightweight applications and stainless steel for higher torque or corrosive environments. Maintenance needs, particularly disc replacement due to wear, also influence the choice of coupling.