What Is a High-Strength Bolt?

Unlike bolts used in general machinery, high-strength bolts are much more substantial.

The commonly used steel material called SS400 has a tensile strength of 400 N/mm2, but the material used for High strength bolts has a strength of 800 N/mm2 at the lowest.

Therefore, it is used in construction, not for general mechanical applications. In particular, they are widely used as bolts for fixing steel materials together in friction-jointed joints, often employed in steel construction.

These bolts are still widely used today.

Uses of High-Strength Bolts

Uses of high-strength bolts are mainly in the field of construction. There are many ways to build a building structure; among them, it is straightforward to construct a building structure with steel frames compared to concrete structures.

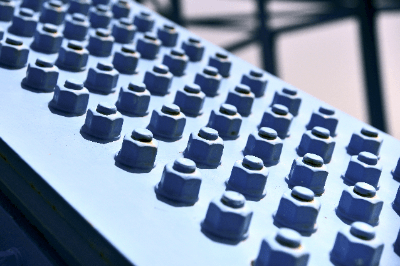

High-strength bolts are used to join steel members together.

In the case of steel construction, welding steel frames together is very time-consuming, and the quality is not stable with on-site welding, so they are joined by a method called friction welding.

High-strength bolts are used because high torque is required to generate this frictional force.

Principle of High Strength Bolts

Since high-strength bolts are used in steel-frame joints, where high torque is required, chrome and molybdenum steel has been used for many years, but nowadays, low-carbon boron-added steel is widely used.

This has made it possible to prevent delayed fracture, which has been a problem with chromium and chrome molybdenum steels. High-strength bolts are divided into two types according to their shape and usage: Torsia-type high-strength bolts and high-strength hexagonal bolts.

The main difference between these two bolts is that the torusia-type high-strength bolt has a particular shape for the fastening portion and requires a dedicated tool. However, the tightening part is shaped to break if tightened with more than the specified torque, so torque management is straightforward.

On the other hand, High strength bolts can be tightened using the same wrenches and other tools as general bolts and nuts, but torque control may be neglected.

The general disadvantage of high-strength bolts is that they are more expensive than ordinary hex bolts. However, since hexagonal bolts of common materials cannot handle high torque, they are always used in construction sites.

High-Strength Bolt Friction Joints

High-strength bolt friction joining is a method of joining steel plates by frictional force generated on the contact surfaces of the steel plates by tightening them together with the strong axial force applied to the high-strength bolt. This method is used in construction fields such as road bridges and skyscrapers. Stronger fastening is required because of the additional surface bonding force between the steel plates compared to fastening with only the axial force of a normal bolt. Another advantage of this method is that it does not require firearms like rivet joints and does not require professional skills like welding.

Since the frictional force between steel plates must be high, the contact surfaces must be slip-resistant. Slip resistance is determined by the “slip coefficient” specified in the Building Standard Law, which must be 0.45 or higher. The higher the slip coefficient, the greater the resistance and frictional force, so a friction surface treatment is applied to roughen the surface of the steel plate in advance.

There are three types of friction surface treatments: “red rust treatment,” “shot blasting,” and “phosphate treatment.

Red Rust Generation Treatment

In the red rust-generating treatment, the contact area of the steel plate is roughened by applying a grinder, etc., and is oxidized in the atmosphere.

Shot Blast Treatment

Shot blasting treatment is a method in which fine balls (silica sand or steel balls) called media are blown together with compressed air to roughen the surface with fine irregularities. After shot blasting, the surface loses its metallic luster.

Phosphate Treatment

This simple method of applying a phosphate chemical to the bonding surface is widely used because it requires little time and effort. However, working in rainy or humid environments is strictly forbidden, as moisture will cause the bolts to fail to adhere to the surface and peel off.

Difference Between High Strength Bolts and High Tension Bolts

High-strength and high-tensile bolts are identical, and they are no different. They are called “high-strength” and “high-tension” because they are made of high-tension steel (high-tension steel). There are different types of high-tensile steel, including those with a higher nickel content of about 3% to increase salt resistance near the coast and weather-resistant ones with increased amounts of Ni and Cu added to increase atmospheric corrosion resistance.

How to Read High-Strength Bolt

It is read as a “high-strength bolt” or “high-tension bolt.” Note that they are also called high-tension bolts.