What Is a Load Measuring Instrument?

A load measuring instrument is a device used to measure the force that pulls or pushes an object.

A load measuring instrument is a device used to measure the force that pulls or pushes an object.

Typical types of load measuring instruments include force gauges, load cells, and torque transducers, each of which can detect different types of forces.

For example, force gauges measure the force generated by pushing and pulling, load cells are used as force transducers, and torque gauges measure rotational and torsional forces.

Uses of Load Measuring Instruments

Load measuring instruments are used to express the hardness of materials numerically, the magnitude of forces generated when operating equipment, and the magnitude of forces applied to various objects.

1. Force Gauge

Force gauges are mainly used when they are handheld and exert a direct push-pull action on the object to be measured. For example, it is used to measure the force applied during actions such as opening and closing a fastener or a shutter.

Also, by fixing a force gauge on a stand, uniform and reproducible measurement is possible. And it is also used for hardness test and opening/closing test of the object to be measured.

2. Load Cell

Load cells are mainly used as transducers for load measuring instruments attached to equipment and other devices. The size and shape of the load cell used varies depending on the object to be measured, ranging from small to large shapes.

3. Torque Transducer

Torque transducers are used to measure rotational torque and twisting force. The measurement is made by holding either the object to be measured or the torque meter with the hand and performing a tightening or opening/closing motion on the one not being held.

In many cases, it is used to measure the opening and closing force of a cap or the screw tightening action force. Other applications include measuring the output torque of engines, etc., and the load torque of rotating machinery.

Principle of Load Measurement Instruments

Force gauges are used to measure force generated by pushing and pulling, peeling, friction, and so on. There are two types of force gauges: one uses a spring, and the other has a built-in load cell.

The spring-loaded type mechanically indicates the amount of deformation of a spring due to load. The load cell converts the measured force into an electrical signal and converts it into a numerical value. There are several conversion methods, of which the strain gage type is the most commonly used.

This method uses strain gages that can measure strain from the amount of deformation caused by the force applied. In addition, the piezo piezoelectric, thin metal film, capacitance, and optical fiber types are also used in some cases.

Torque meters measure force in rotational motion by sensing changes in the torsional angle of a rotating shaft as a phase difference, which is converted into an electrical signal.

Other Information on Load Measuring Instruments

1. Load Measuring Instruments and Load Cells

Load measuring instruments with digital displays will utilize load cells to detect the load. A load cell is a load sensor with a strain gage attached to a metal part. The metal part of the load cell is designed according to the load capacity, and the amount of deformation of the metal due to the load is converted into a change in resistance value by the expansion and contraction of the strain gage, which is then electrically amplified and converted into a load value. The amplified load is displayed on a digital readout.

Load measuring instruments using load cells have a high accuracy in displaying load values. However, the load measuring instrument’s load cell part must be handled with care because the metal is susceptible to plastic deformation due to impact or overloading. It is important not to drop the load cell, give it a shock, or overload it.

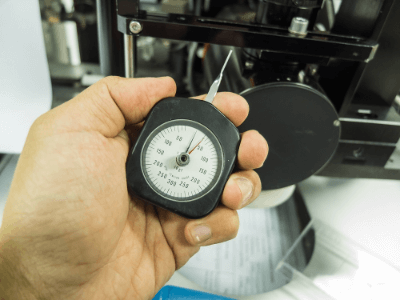

2. Tension Gauge

Tension gauges are load measuring instruments used to measure the tension of drive belts, chains, and other moving parts. Tension refers to the force pulled between two points, and is calculated using the distance between the two points, the load applied perpendicular to the direction of tension, and the “deflection” of the belt or other object due to this load.

In addition to transmission belts, the tension force of paper in printing presses, thread tension in weaving, and the tension force of steel plates sent from a steel plate roll to a press are also measured in the same way. There are two types of tension gauges: analog and digital.

There are those that can simultaneously measure the amount of deflection, and those that hold a defined two-point distance as the mechanism of the gauge and display the tension in a proprietary standard. It may also refer to the digital or analog force gauge itself.