What Is a Windlass?

A windlass is a device designed for winding sheet products such as film or hoses. It’s primarily used for winding sheets and similar products, streamlining handling and storage. By coiling long products onto a core, it enables compact handling without compromising the quality of the products.

Windlasses are crucial for optimizing material winding processes and enhancing organization and storage. These devices are ubiquitous in various industrial settings and everyday life, playing a vital role in efficient material handling and management.

Uses of Windlass

Windlasses have diverse applications:

- Yarn and Textile Production: Used in spinning and weaving mills to wind yarn, enhancing handling and processing.

- Wire and Cable Manufacturing: Windlasses coil long wires and cables, aiding in handling and storage.

- Fishing Tackle: Employed for winding fishing lines, maintaining organization, and preventing tangling.

- Chemical Products Manufacturing: Used in reeling sheet products like plastic films and adhesive tapes, ensuring constant winding force to avoid wrinkles.

Principle of Windlass

Windlasses consist of several components:

1. Frame

Provides structural support, typically made of steel or other metals.

2. Motor

Powers the device, selected based on material weight and winding speed. In the case of manual winding, the motor is omitted and a handle is attached instead.

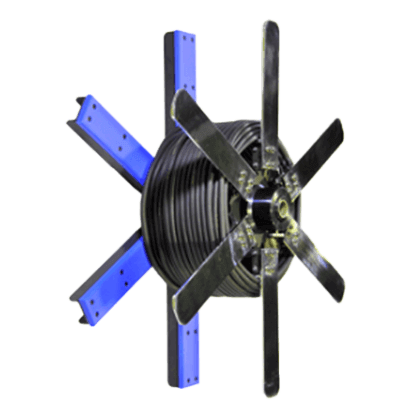

3. Drum

The core component where materials are wound. Its design varies based on material characteristics.

4. Control Unit

The winder is operated by a control unit. The controller adjusts the parameters of the winding process, such as winding speed and traverse control.

A constant tension must be maintained if the windlass is to wind the sheet product without wrinkling or sagging. However, since the roll diameter increases as the winding progresses, tension cannot be maintained simply by keeping the output of the motor on the take-up shaft constant.

To maintain constant tension during winding, open-loop or feedback control systems like a dancer roll are used.

Types of Windlass

Windlasses come in various forms:

- Turret Windlass: Features multiple winding shafts, automating the winding process.

- Bobbin Windlass: Ideal for winding linear products, ensuring uniform winding diameter and preventing product entanglement.