What Is a Flexible Coupling?

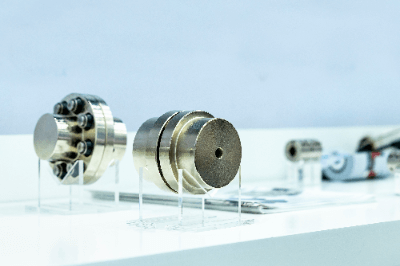

A flexible coupling is a shaft coupling with deflection properties.

The shaft coupling, also called a coupling, is installed between a drive shaft and the drive shaft of a motor or other equipment. A shaft coupling, also called a coupling, is a component installed between a drive shaft and a drive shaft of an engine to transmit power.

Uses of Flexible Couplings

When it is difficult to align the shaft lines of two shafts to be connected, or when vibration or shock is to be mitigated, we use flexible couplings. It is used when you want to attach an existing drive to another driven device or when you want to prevent deformation of the driven side due to heat from the drive side. When two shafts of different diameters are coupled, it prevents heat transfer from the drive side to the driven side.

Principle of Flexible Couplings

A flexible coupling incorporates a deflecting material such as rubber or spring. These absorb vibration and shaft misalignment to enable smooth power transmission. Even if the shaft is affixed accurately, temperature changes and aging will cause gradual misalignment, vibration, and damage.

When the effects of shock and vibration are significant or when smooth rotation transmission is required over a long period, shaft couplings are often used. Due to the characteristics of the parts, durability, and load-carrying capacity vary depending on the material, so it is necessary to select a shaft coupling that matches the intended use and period of service.

Types of Flexible Couplings

Rubber shaft couplings are sometimes used when electrical insulation is required in addition to vibration and shock mitigation applications. Specifications such as torque and rotation speed of the application will call for the need for Flexible couplings. The major types of flexible couplings are listed below.

- Flange-type flexible coupling

- Gear-type shaft coupling

- Rubber shaft coupling

- Metal spring shaft coupling

- Roller chain shaft coupling

- Diaphragm type shaft coupling

Other Information on Flexible Couplings

- Flexible Couplings Centering Tolerance

Always perform centering adjustments when installing rotating machines or restoring them for maintenance. Adjust the flexible coupling in the face and circumferential directions according to the required accuracy. In most cases, centering adjustment is performed with a general centering tolerance of 5/100 mm or less for flexible couplings. However, as an exception, the size may be specified for each coupling, so the adjustment for centering should be made after confirming the manufacturer’s tolerance.

Adjustment of centering requires adjustment of the misalignment between the surfaces of the couplings, the misalignment in the plane direction, and the misalignment in the circumferential direction, respectively. It is compensated by inserting a metal plate for adjustment on the drive side and adjusting the motor’s position.

- Difference Between a Flexible Coupling and a Fixed Shaft Coupling

There are two types of shaft couplings: flexible couplings and fixed shaft couplings. While a flexible coupling transmits power while absorbing misalignment, a fixed shaft coupling, also known as a rigid coupling reamer bolt, is firmly fixed and transmits energy. The mounting position must be accurate, and the shaft center must match.

The installation itself is simple and is completed by tightening the reamer bolt. The most commonly used type is the flange-type fixed shaft coupling. While flexible couplings use rubber or other shock-absorbing materials on the bolts that secure the couplings together, fixed shaft couplings do not have any absorbing materials.