What Is PET Film?

PET Film is a polymer film with excellent heat resistance and strength.

PET Film is a polymer film with excellent heat resistance and strength.

It is used in a wide range of applications from the industrial field to the daily life field, such as for packaging. Its official name is polyethylene terephthalate. It is also used as a material for PET bottles.

In addition to PET film, there are also PP (Polypropylene) and PVC (Polyvinyl Chloride) films. Compared to these two types of films, PET film is less flexible, but has superior smoothness, heat resistance, heat expansion resistance, solvent resistance, and weather resistance.

Uses of PET Film

PET film is a high-performance polymer that is also inexpensive, making it extremely versatile.

For example, its heat resistance is utilized in packaging materials for retort pouch foods, and its high smoothness is utilized in laminate base materials, among many other properties. In addition, its excellent optical properties have expanded its field of application to include protective films for displays.

Various grades of products exist, as the optical properties of the film vary depending on the manufacturing method, additives, and special processing.

Characteristics of PET Film

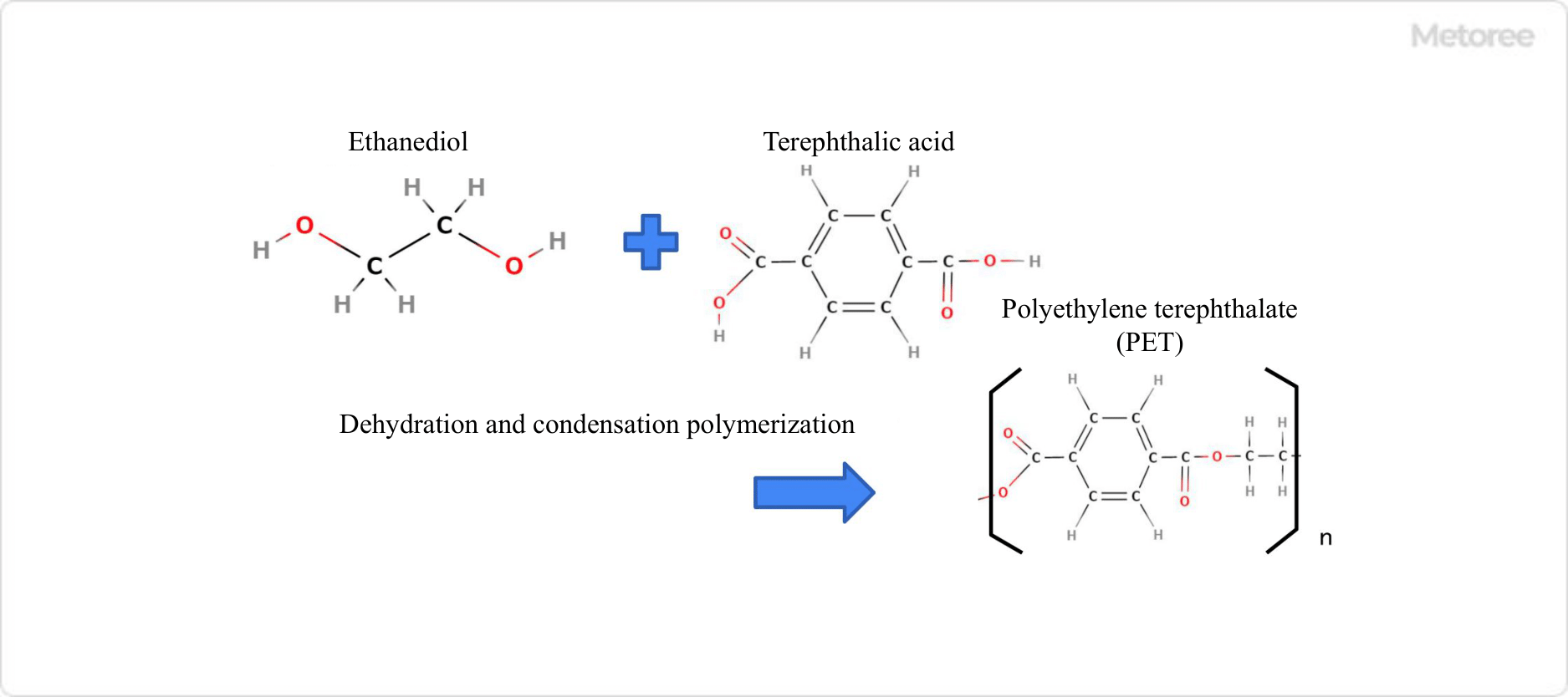

Figure 2. Polymerization of PET

The properties of PET films are due to its structure: PET is a thermoplastic polyester obtained through a polycondensation reaction between ethylene glycol and terephthalic acid.

Its linear molecular structure allows for molecular reorientation, which contributes to its strength.

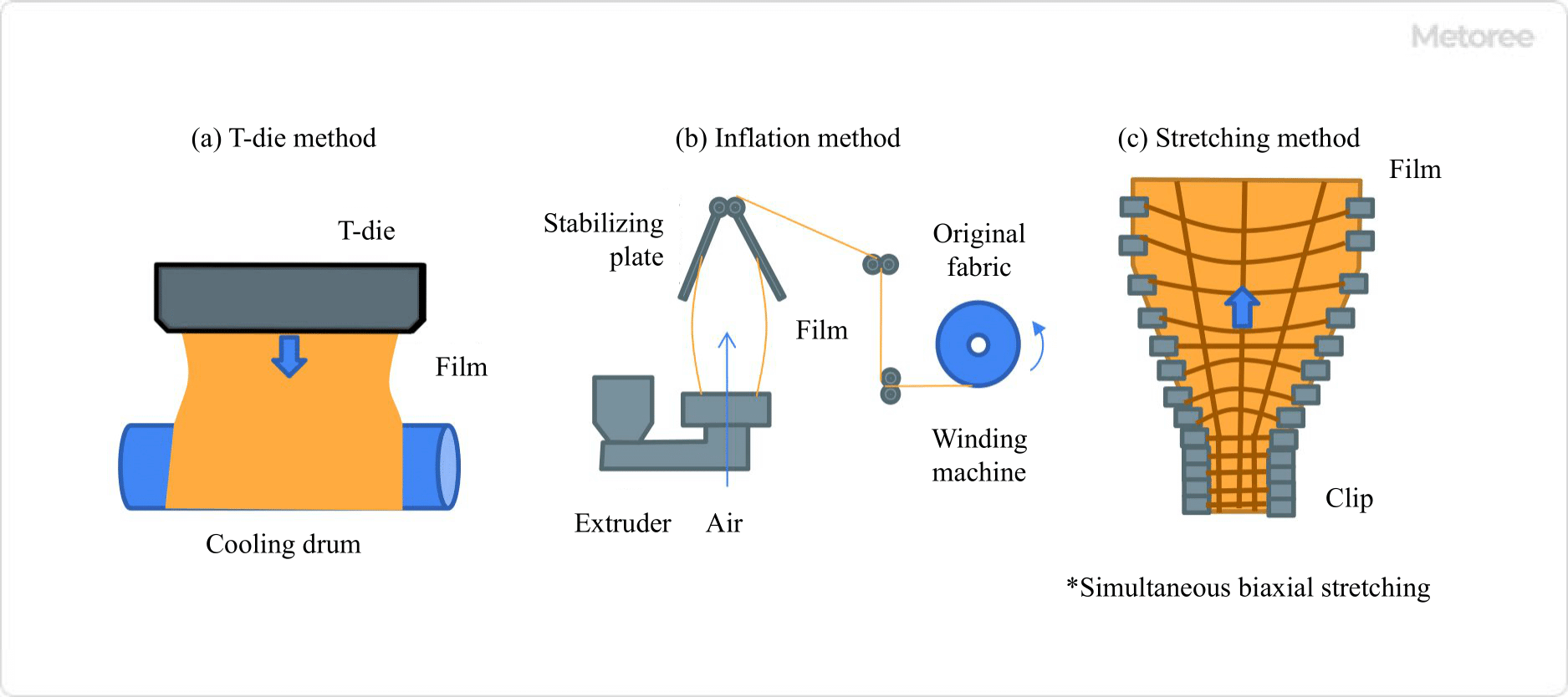

There are several methods for manufacturing PET films, including the T-die method, inflation method, and stretching method.

Figure 3. Film production method

1. T-Die Method

Material is extruded from a straight mold called a T-die installed at the end of an extruder to form a film. The extruded PET film is cooled by cooling rollers to complete the film.

2. Inflation Method

Resin is extruded from a ring-shaped mold into a film and then blown with cold air to form the film. The inflation method is used for bagging rather than film applications.

3.Stretching Method

This is a manufacturing method in which the film is pulled in a uniaxial or biaxial direction to align the molecules in a certain direction. This method is best suited for manufacturing PET film because the molecules rearrange themselves neatly and the strength is improved.

Other Information on PET Film

PET Film Processing

PET film can be processed to add functions not normally available or to greatly improve its properties. It is important to control the quality and physical properties according to the intended use, as processing increases the cost.