What Is a Ball Nose Mill?

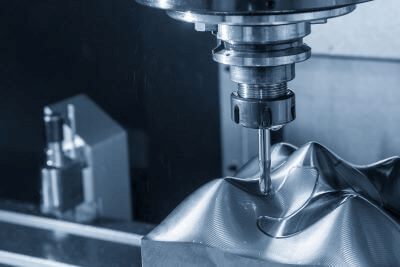

A Ball Nose Mill is a cutting tool used in machine tools that has a spherical tip.

A Ball Nose Mill is a cutting tool used in machine tools that has a spherical tip.

The cross-sectional shape of the cutting surface of an ordinary nose mill is right-angled because of its flat shape, whereas the cross-sectional shape of a ball nose mill can be curved when cutting with a ball nose mill.

By using a ball nose mill, a curved surface can be freely formed as long as the radius of curvature is equal to or greater than the ball radius of the ball nose mill, without using a 5-axis machining center with a mechanism to tilt the cutting tool.

Uses of Ball Nose Mills

Since Ball Nose Mills are suitable for cutting to form curved surfaces, they are used to cut fillet sections to prevent parts and debris from accumulating in the corners of the bottom surface.

In addition, by cutting with numerical control using NC milling machines, etc. based on the shape designed with CAD software, smooth curved surfaces that are difficult to form with ordinary square nose mills can be formed if the radius of curvature is greater than the ball radius of the ball nose mill.

Principle of Ball Nose Mill

Ball Nose Mills can be used in conjunction with NC machine tools to easily cut curved surface shapes. However, there are several disadvantages compared to square nose mills.

Ball Nose Mills have a small cross-sectional area of the cutting edge, which makes them less rigid and more prone to spills.

The cross-section of a ball nose mill’s blade is curved, and the tool diameter varies greatly depending on the position of contact with the material to be cut.

Even when the feed rate and rotation speed are set at a constant level, excessive load applied to the tip of the nosemill due to the levelness or surface roughness of the workpiece surface can result in edge spills.

Other disadvantages include the inability to machine right-angled corners on the bottom surface and poor cutting swarf discharge, making the square nose mill superior as a general-purpose nose mill.

The quality of the machined surface varies greatly depending on the position of contact with the material to be machined, so the use of machining equipment with high-precision positioning accuracy and surface treatment after machining are necessary if smooth curved surfaces are to be formed.

Other Information on Ball Nose Mills

1. How to Use Ball Nose Mill

Since the cutting edge is shaped like a round ball, ball nose mills are used to cut not only flat surfaces and sides, but also spherical surfaces and any other shapes, as well as for corner radiusing using the radius of the nose mill. Due to the spherical shape, the tool diameter gradually increases from the tip of the blade to the outside, and the rotational speed also changes.

Since the tool diameter at the tip is zero, the rotation speed remains zero no matter how fast the tool is rotated. Therefore, machining only at the tip where the rotation is zero will not produce good results for either the cutter or the workpiece, such as a dirty surface or spilled edges.

To achieve good machining results with a ball nose mill, it is important to use as much of the outside of the cutting surface as possible and to contact the workpiece at a high rotational speed.

With a 5-axis machine that can freely change the angle of the table and spindle, the nose mill or table can be tilted to any angle to cut to obtain good accuracy.

It is not impossible to machine a flat surface with a ball nose mill. Although it takes more time than with a milling cutter, it is possible to machine a flat surface by shifting the ball diameter by half (10 mm for 20 mm) and machining it as if it were filled with a flat surface.

In this case, the surface will be noticeably uneven and not clean. Although it is limited to roughing applications only, a single ball nose mill can be used universally for machining complex surface shapes to flat surfaces and side machining.

2. Tipped Ball Nose Mill

For large-diameter ball nose mills with a diameter larger than 20 mm, in addition to the solid type, there are other types of mills with two removable inserts. The replaceable inserts cannot be reground and used again, as is the case with solid mills.

However, it is easy and time-saving to change blades, as they can simply be replaced when the sharpness deteriorates. There are two types of tips, one for roughing and the other for finishing.

For roughing, one tip is symmetrical at the top and bottom. In many cases, one tip can be used for two machining operations if the tip is turned over and mounted after use. Balls for finishing are one-piece inserts shaped like a half-moon and cannot be re-machined by rearranging the cutting edges as in the case of roughing.

3. Machines Used With Ball Nose Mills

The main types of machines used in conjunction with ball nose mills are 3-axis CNC routers, 4-axis CNC routers, and 5-axis CNC routers. Each CNC router reads 3D data created by CAD/CAM software and performs machining using ball nose mills.

Machining accuracy can be adjusted by the radius of the ball nose mill’s cutting edge, the number of revolutions, and the speed of progression. Recently, machines equipped with high-speed cutting functions have also been introduced specifically for high-speed machining.

3-Axis CNC Router

The 3-axis CNC router is controlled by the X, Y, and Z axes and is suitable for flat surface machining and shallow grooving.

4-Axis CNC Router

The 4-axis CNC router has a rotary axis in addition to the X, Y, and Z axes, and can process while rotating, making it suitable for three-dimensional machining and engraving.

5-Axis CNC Router

The 5-axis CNC router has an inclined axis in addition to the 4-axis CNC router and can process more complex shapes.