What Is a Pull Box?

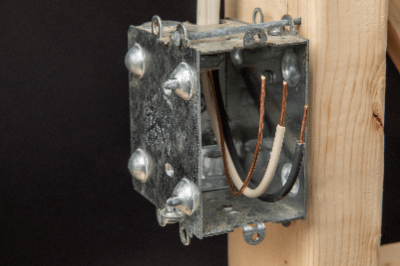

Pull Boxes are box-shaped components used to protect wiring and circuit connections.

Generally installed outdoors, they protect wiring and circuits from rainwater and dust. Pull Boxes also have ventilation holes to prevent overheating and rainwater from filling the box. Pull Boxes are provided with holes for wiring, allowing wiring to be neatly organized.

They are also used not only to protect wiring and circuits, but also to enhance safety. The rule that wires must not be connected to each other in a conduit is stipulated in the technical standards for electrical equipment. If you want to branch a power supply, you must protect the connection with a Pull Box or similar device.

There is a similar product called an outlet box, the size of which is determined by the JIS standard, but there is no JIS standard for pull boxes. Therefore, a wide variety of sizes can be selected according to the installation location.

Uses of Pull Boxes

Pull Boxes are used to protect wiring and circuit connections. The purpose is to protect wiring and circuit connections from the outside environment. In outdoor locations, water and moisture can cause circuits to short-circuit.

Pull Boxes can be used to prevent and protect against rainwater intrusion. They may also be used to connect electrical equipment and wiring. In many cases, wiring in large factories is thicker than recommended to account for voltage drops.

Since this may not fit into the lead boxes of electrical equipment, etc., a pull box may be installed in front of the box to connect it to the thinner wiring. In addition, devices such as breakers and terminal blocks may be housed in the box.

Principle of Pull Boxes

Pull Boxes are box-like structures that house wiring and circuits and are designed to be impervious to external influences. Ventilation holes are provided for wiring connections, ventilation, and water drainage.

The main functions of Pull Boxes are to protect and organize wiring. Wiring can be damaged by the external environment or can suffer poor contact due to human manipulation. Pull Boxes protect wiring by encasing it in a box-like structure and preventing external influences.

In some cases, terminal blocks are provided to accommodate the wiring, and products are also available that make it easy to make wiring connections. Pull Boxes are also useful for organizing wiring.

If multiple wires are routed in a messy manner, they may rub against each other. Pull Boxes can be used to organize and safely manage wiring.

Types of Pull Boxes

There are two types of Pull Boxes, plastic and metal, and they are used according to the environment of the location where you want to install them.

1. Resin Pull Box

Resin pull boxes are made of FRP resin or polyvinyl chloride resin. They are weak against direct sunlight, so they are not suitable for outdoor locations with strong sunlight. Compared to metal objects, there is no risk of rust or corrosion. Used indoors or in corrosive environments.

2. Metal

Iron and stainless steel are used for metal. In the case of iron, it is often plated with hot-dip zinc or the like. It is characterized by its high impact resistance and sturdiness.

Compared to resin, it also has superior heat resistance, making it suitable for areas exposed to strong sunlight. However, iron may rust or corrode, making it unsuitable for seaside or hot spring areas where there is a lot of water. It also has the disadvantage of allowing electricity to pass through in case of leakage.

How to Select a Pull Box

When selecting a pull box, pay attention to the material and size.

1. Material

Select a material that is suitable for the environment in which it will be used. For corrosive environments, it is preferable to use stainless steel or resin. However, in general environments or indoors, inexpensive steel should be selected.

2. Size

Select the size according to the number of incoming wires and wire thickness. It is desirable to select a slightly larger product because there is a possibility that additional installation work may be performed at a later date. If a smaller size is selected, the wires may rub against the inside of the product.

3. Color

Paint color and body color should be selected to match the surroundings and to be inconspicuous. Depending on the application, a product with a terminal block may be selected.