What Is Prepreg?

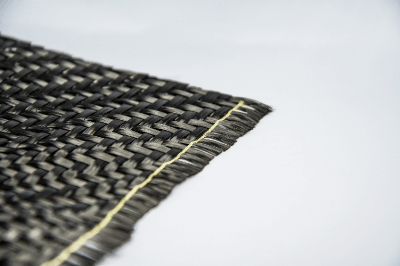

Prepreg is a composite material made by impregnating a sheet of fiber with resin, and is one of the raw materials used in the molding of fiber-reinforced plastics.

Prepreg is a composite material made by impregnating a sheet of fiber with resin, and is one of the raw materials used in the molding of fiber-reinforced plastics.

The resin used for impregnation is a thermosetting resin such as epoxy that hardens upon heating, or a thermoplastic resin that softens upon heating and hardens upon cooling. Carbon fiber and glass fiber are often used as fibers.

By combining fibers and impregnating resins, it is possible to create a material that meets the intended purpose.

Uses of Prepreg

In addition to carbon and glass fibers, aramid fibers are also used as fibers for Prepreg. Their respective applications are as follows:

1. Carbon Fiber Prepreg

Prepreg made of carbon fiber is called carbon prepreg and is used as a molding material for carbon fiber reinforced plastics (CFRP). CFRP is characterized by its light weight, high strength, and high stiffness.

It also has electronic conductivity due to the use of conductive carbon fibers. Although CFRP is mainly used in the aircraft industry, it also has a wide range of other applications, such as in automobiles, golf club shafts, and tennis racket frames.

2. Glass Fiber Prepreg

Glass fiber Prepreg is used as a molding material for Glass Fiber Reinforced Plastics (GFRP). GFRP features greater specific strength than metal materials, is lighter, and is not electronically conductive due to the use of insulating glass fibers.

Taking advantage of this feature, GFRP is used in antenna covers, printed circuit boards, etc.

3. Aramid Fiber-Reinforced Plastics

Aramid fibers are very light and difficult to break, and have high impact resistance and strength. On the other hand, they are more difficult to break than carbon and glass fibers, making it difficult to mold them into any shape and to post-process them.

Because of its high impact resistance and strength, it is used in aircraft, various parts for space applications, and pressure vessels.

Principle of Prepreg

Prepreg has a shape and physical properties that facilitate its use as a molding material for CFRP and GFRP. Since resin and fibers are composited in a predetermined quantity ratio to form a sheet, it is possible to produce molded products with less variation in performance than with other CFRP manufacturing methods.

Prepreg is impregnated with resin while the fibers are arranged in one direction. This is called UD material, which is strong in the direction of the fibers but very weak in the vertical direction of the fibers. When molding into Fiber Reinforced Plastics (FRP), it is important to stack the fibers in different directions.

By changing the direction of transition, high-strength FRP is formed for any direction. Prepregs made by impregnating woven fabrics with resin are also available, and are called fabric materials.

Resin impregnation varies depending on the application and the difference between CFRP and GFRP, but thermosetting resins such as epoxy resin, unsaturated polyester resin, phenolic resin, and thermoplastic resins such as polypropylene, polyamide, polycarbonate, and polyetheretherketone are also used in many cases.

Prepregs made of thermosetting resins, in particular, have a tacky surface because they remain uncured until they are molded into FRP, and they must be sealed and frozen to prevent further curing during storage.

Other Information on Prepreg

How Prepreg is Manufactured

Prepreg manufacturing methods differ depending on whether the resin to be impregnated is thermosetting or thermoplastic.

1. Thermosetting resin

A pre-cured resin film is formed and heat-pressed together with uniaxially aligned fibers or fiber fabrics. The fiber content can be controlled by the thickness of the film, and uneven fiber content is unlikely to occur.

2. Thermoplastic resin

Since the resin itself has high viscosity, there are two methods: dissolving the resin in a solvent, impregnating it, and drying the solvent; or grinding the resin into small pieces, sprinkling it on fibers or textiles, and heat pressing it.