What Is a Fiber Laser?

A fiber laser is a type of laser where the medium is an optical fiber doped with rare earth elements. These lasers typically operate at wavelengths of 1030~1070nm.

A fiber laser is a type of laser where the medium is an optical fiber doped with rare earth elements. These lasers typically operate at wavelengths of 1030~1070nm.

There are two main types of fiber laser operations: continuous wave (CW) and pulse oscillation. CW is used for applications like welding and cutting due to its high output power, while pulsed oscillation is preferred for marking and microfabrication due to its lower output power.

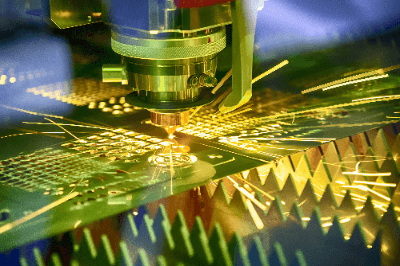

Uses of Fiber Lasers

Fiber lasers are utilized in various fields for tasks such as welding, cutting, marking, and fusing. They are particularly effective in processing materials like aluminum, copper, and brass which are challenging to handle with CO2 lasers due to strong reflections. High beam quality makes fiber lasers suitable for microfabrication, producing a small spot diameter.

Pulsed fiber lasers are also popular for marking on various materials, including metals, plastics, and resins, and are used in part printing and barcode printing. They offer diverse marking methods like deep drilling, black and white marking, and surface layer peeling.

Principle of Fiber Lasers

Fiber lasers consist of a resonator, a laser medium (optical fiber), an excitation source, and resonance mirrors. The core of these lasers is a double-clad fiber doped with rare earth elements. When excited by light from a laser diode (LD), the light reflects within the claddings, is absorbed by the core, and induces emission. Resonance mirrors at the fiber’s ends amplify this emission.

Depending on the type of operation (CW or pulse), fiber lasers have different oscillator structures:

- Continuous Oscillation (CW): In CW fiber lasers, pump light from the LD reaches the resonator through a pump combiner, using a fiber Bragg grating instead of a resonance mirror. The amplified light is then transmitted through the output fiber, negating the need for optical adjustment.

- Pulse Oscillation: Pulsed oscillation fiber lasers, such as the MOPA type, use a pulse generator to pulse the seed light (LD). Light is amplified in two stages through an optical fiber amplifier, with adjustable pulse width and repetition frequency.

Differences between Fiber Lasers and CO2 Lasers

Fiber lasers offer advantages over CO2 lasers in terms of energy efficiency, maintenance, and processing speed. They consume significantly less power, do not require laser gas, and have a simpler optical system. While fiber lasers can process faster than CO2 lasers, they have limitations in cutting thick metals and may have higher initial costs.

Welding with Fiber Lasers

Fiber lasers are becoming a promising alternative to CO2 lasers in metal welding, offering higher luminous efficiency and lower running costs. Technological advancements have addressed issues like splatter during welding.

Price of Fiber Lasers

The cost of fiber lasers varies depending on specifications but generally falls in the hundreds of thousands of yen range. Laser processing equipment can be several million yen or more, making the overall investment in welding equipment substantial.