What Is a Syringe Pump?

A Syringe Pump is a machine that continuously pumps or aspirates a precise volume and speed of solution or medicine from a syringe.

A Syringe Pump is a machine that continuously pumps or aspirates a precise volume and speed of solution or medicine from a syringe.

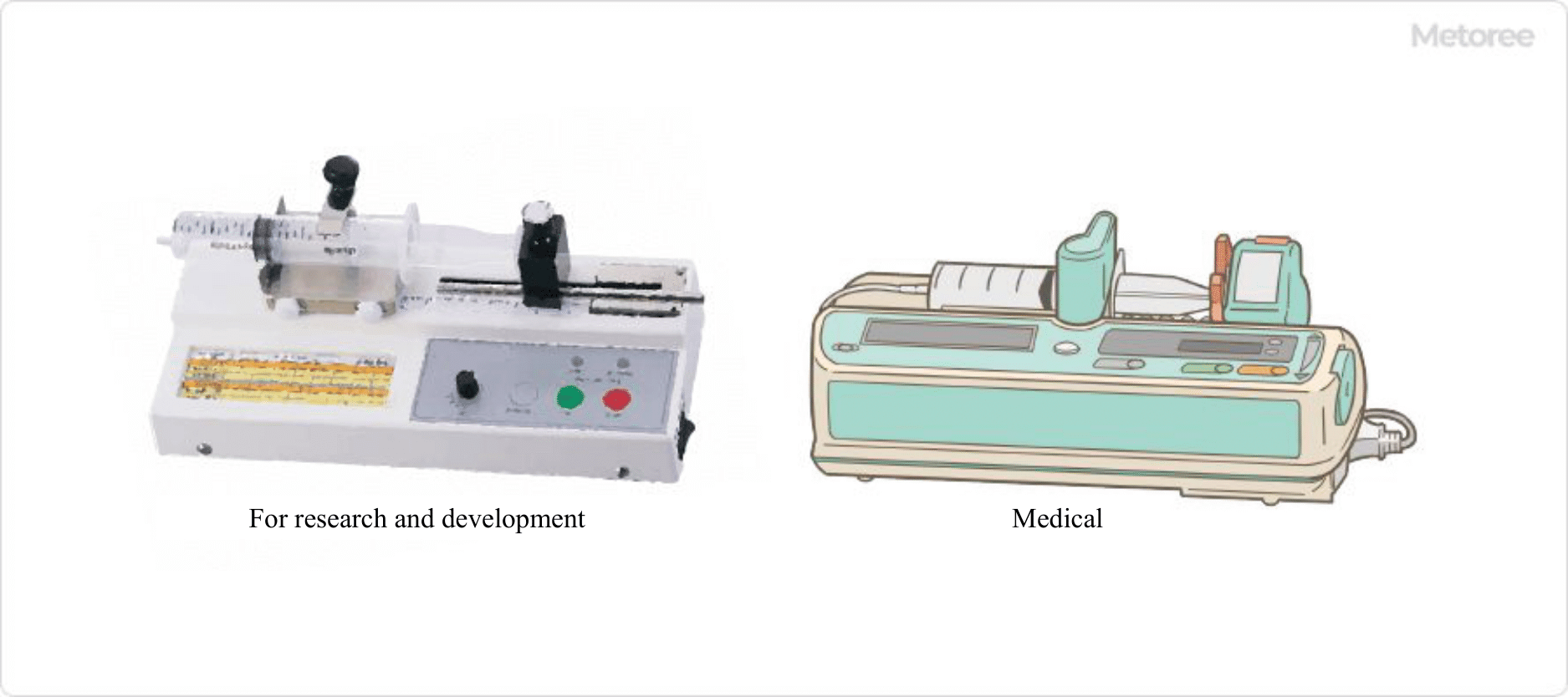

There are two types of syringe pumps: those for medical use and those for research and development.

Syringe pumps move the plunger of a syringe at a constant speed according to the size of the syringe in order to pump or aspirate precisely at a preset volume and time.

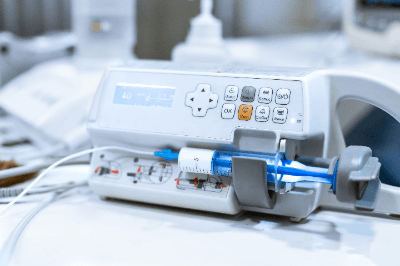

Figure 1. Syringe pump

Uses of Syringe Pumps

There are two main types of uses for syringe pumps: medical and research.

The purpose of syringe pumps is to pump or aspirate a precise amount of solution or drug at a constant speed while controlling the flow rate.

1. Syringe Pumps for Medical Use

Medical syringe pumps are used to administer exact and precise doses of medication in doses of 50 mL or less per dose. Compared to infusion pumps that use elastic tubing, syringe pumps use rigid syringes to ensure accurate infusion.

2.Syringe Pumps for Research and Development

Syringe pumps for research and development are used in applications that require precise, pulseless, metered volume infusion.

Applications include flow micro-reactions, reagent drops, pharmacological and animal experiments, and injection into analytical instruments.

Fluid volumes may be very small and may have additional characteristics that make them unsuitable for clinical use.

Other applications include the dispensing of various fluids such as adhesives, silver, solder paste, grease, chemicals, liquid crystals, etc., in the manufacture of components and assembly lines in production.

Principle of Syringe Pump

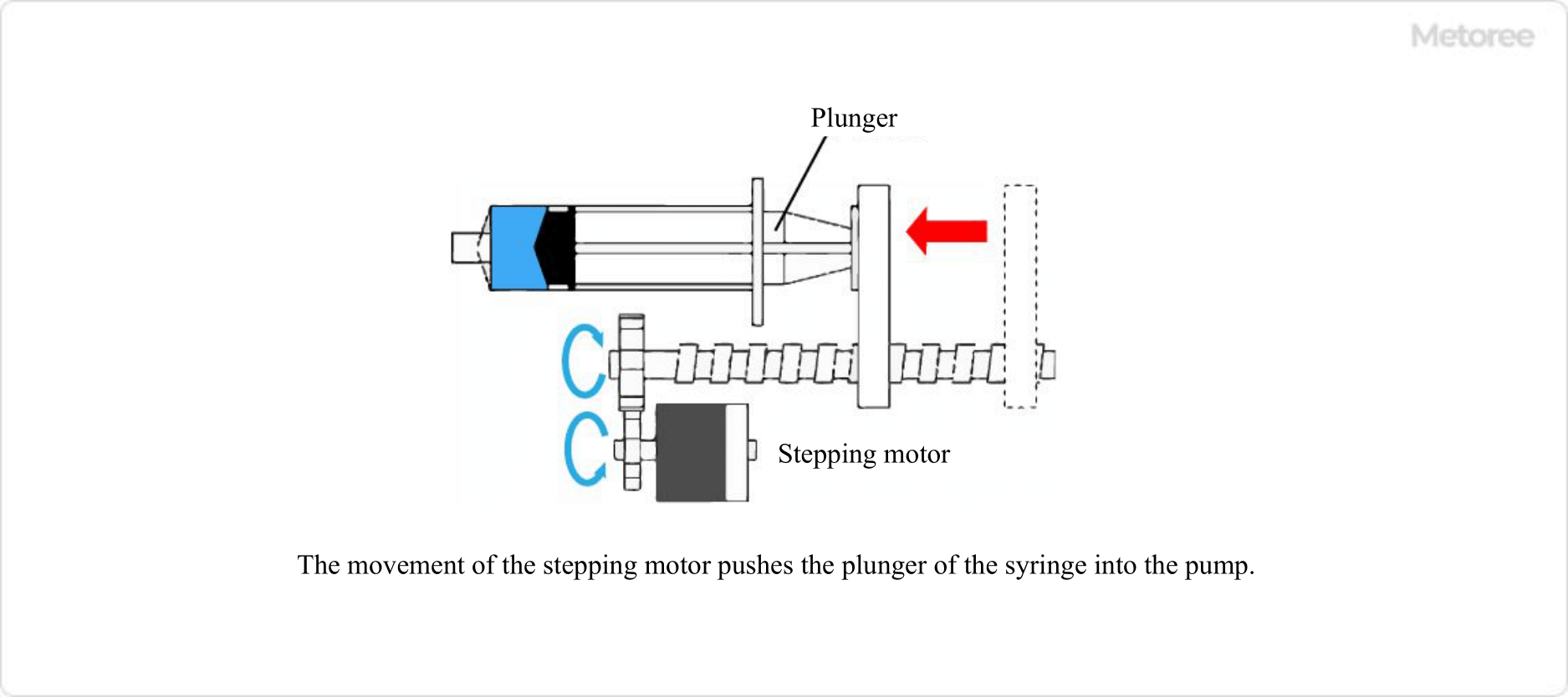

Figure 2. Principle of the syringe pump

A syringe pump pump delivers a constant flow of liquid by fixing the outer cylinder of a syringe and pushing out the inner cylinder with the power of a motor. A stepping motor, which is easily adjustable and can operate at a constant speed, is generally used as the motor.

When syringes are used manually, it is extremely difficult to adjust the flow rate and speed, but with syringe pumps, the motor pushes the syringe at a constant speed, enabling highly accurate flow rate adjustment and pulsation-free pumping.

How to Select a Syringe Pump

As mentioned above, you must first select a different medical/research and development pump for your application. Then, according to your purpose, you should use the one equipped with the necessary functions.

1. For Medical Use

Syringe pumps for medical use are available for 5, 10, 20, 30, 50, and 100 mL syringes, respectively. It is necessary to select a product that matches the volume of drug solution to be used and the desired inflow volume.

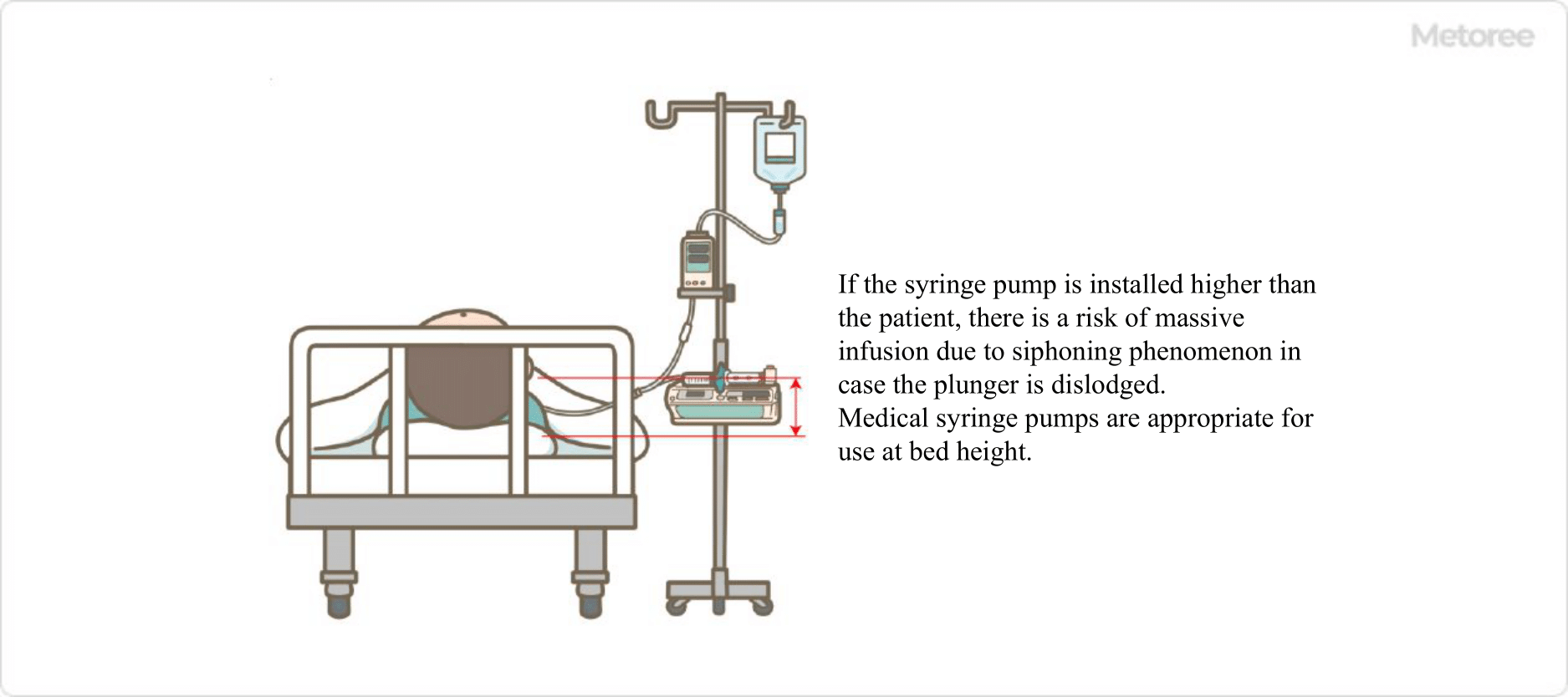

Some products may alert the user with a buzzer sound until the syringe is properly installed as a safety measure. This is to prevent siphoning, a phenomenon in which a large amount of drug is injected into a syringe pump installed at a height higher than the patient’s body due to a drop-off if the syringe pusher is not fixed in place.

Others are equipped with wireless LAN for remote monitoring of pump operation, pulse injection (intermittent injection) settings, and display of gamma volume calculations linked to the injection rate value of the Syringe Pump itself. Some products also allow two syringes to be attached simultaneously to administer different drugs or to perform continuous infusion.

Figure 3. Danger of siphoning phenomenon

2. For Research and Development

There are a variety of sizes available, from those for micro-liter liquid volumes to those for 100-mL liquid volumes. First, it is necessary to select the scale that best suits your application. The basic functions also vary depending on the product, ranging from simple pumping-only models to those capable of pumping/aspirating and programmed pumping.

The control unit can be as simple as a dial to set the flow rate, or as sophisticated as a microcomputer-equipped type. The remote control cable can also be added to allow operation via remote control. For example, the drive unit can be installed in a cold room and the flow rate can be controlled from outside.

Other notable features include the ability to pump high-viscosity liquids such as CMC solutions. Some syringe pumps are pre-installed with syringe data from major manufacturers and can be set up so that all you have to do is make a selection.

Other Information on Syringe Pumps

1. Incidents Related to Syringe Pumps

Incidents related to Syringe Pumps include the following

Incorrect input of pump flow rate setting

Syringe pumps are used to continuously administer medication at a precise volume and rate, and incorrectly entered flow rates can result in serious incidents that can be fatal to patients. Other examples of setting input errors include mistakenly entering the wrong flow rate for Drug A and Drug B, and mistakenly entering the wrong flow rate units.

Failure of the pump’s air bubble detector

Syringe pumps are usually designed to detect air bubbles and automatically stop pumping, but there have been reports of cases where the pumps do not stop and air is pumped to the patient side due to equipment malfunction. Even if maintenance and inspections are performed, such cases can still occur, so it is important to enter the expected volume when using the pump.

In addition, as a background or factor in these cases, lack of knowledge and experience of medical personnel was reported in many cases. Familiarization with the procedure manual and reeducation on how to use it are also important to prevent these cases from occurring.