What Is a Vane Pump

A vane pump is a positive displacement pump that uses multiple flat or vane-shaped plates, called vanes, to change the volume inside the pump for transport.

A vane pump is a positive displacement pump that uses multiple flat or vane-shaped plates, called vanes, to change the volume inside the pump for transport.

The vane is extended in the centrifugal direction by the centrifugal force of the eccentric rotor. At this time, the fluid between the vanes changes volume, and the pump functions by compressing and discharging the fluid that is sucked in.

Vane pumps are characterized by their simple structure, low noise, high safety, and relatively low cost.

Uses of Vane Pumps

Vane pumps are used in a variety of industrial applications. The following are examples of applications:

- Conveying cleaning solutions and cooling water in the semiconductor manufacturing process

- Conveying lubricants and lubricating oils

- Conveying drinking water in potable water plants

- Conveying ink in printing presses

- Conveying operating oil in automotive hydraulic systems

When selecting a vane pump, it is necessary to consider the discharge volume, operating pressure, power source used, size, and degree of noise.

Principle of Vane Pumps

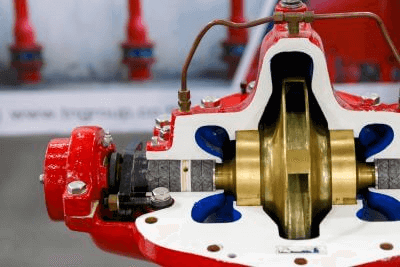

A vane pump consists of an eccentric rotor with multiple vanes, a casing, a suction port, and a discharge port. The vanes operate in a centrifugal direction and are attached to the rotor joint via a spring. Many products are held onto the casing by this spring.

During rotation of the pump, fluid drawn in through the suction inlet flows between the vanes. Since the fluid between the vanes is at a lower pressure than at the suction inlet, the fluid flows into the vane.

During the movement of the aspirated fluid, the volume between the vanes decreases and the pressure increases. The high pressure fluid is let out through the outlet to provide lift as a pump.

Since each component has a different function, the materials used also differ.

1. Vane Material

Since the vane is the structural part that wears the most, a material with excellent abrasion resistance is required. At the same time, it is also important to have good seizure resistance and low aggressiveness to mating materials.

Austenitic stainless steels are widely used to meet these requirements. Austenitic stainless steels have excellent corrosion and wear resistance and good formability, making them suitable for vanes that require high precision.

2. Rotor Shaft Material

Rotor shafts are rotating parts and require excellent wear and corrosion resistance. Therefore, austenitic stainless steels, and relatively inexpensive low-alloy steels are used. Since the shape is cylindrical and simple, it does not need to be as machinable as vanes.

3. Casing Material

The part covering the rotor section is called casing, and is made of graphite cast iron or carbon steel castings. The casing must be structurally strong, as it is required to fix and support the rotor and other parts.

However, the structural strength is not as high as that of vanes and rotor shafts, which require high wear resistance. Lightweight aluminum die-cast materials are used instead of cast steel in automotive applications, where there is a high need for weight reduction.

Other Information on Vane Pumps

Failure of Vane Pumps

The two main causes of failure are wear of parts and fluid malfunction. When a vane pump malfunctions, symptoms such as abnormal noise and reduced pump output occur.

Vane pumps discharge fluid by rotation, and since the rotating parts are in constant friction and sliding motion, wear progresses as the pump is used for a longer period of time. When parts wear out, wear powder mixes with the fluid, resulting in abnormal noise without normal flow.

In addition, when the airtightness is reduced due to wear, fluid is lost, resulting in a lower discharge rate. It is important to follow proper operating conditions and take countermeasures by replacing parts periodically.

Failure may also occur due to abnormalities in the fluid. When wear powder is mixed in or the temperature drops, the viscosity of the fluid increases. As a result, load multiplication and abnormal noise may occur, as well as a decrease in the discharge rate.

It is important to maintain parts with cleaning functions, such as strainers, while properly controlling operating conditions.