What Is a Bucket Conveyor?

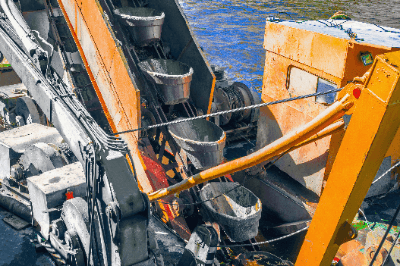

A bucket conveyor is a conveyor with a series of box-like containers (buckets, etc.) with open tops mounted on a belt.

Bucket Conveyor is a type of conveyor used to transport materials by placing the materials to be transported inside the bucket. It is characterized by its ability to convey amorphous materials such as granules and powders without leakage. Another advantage of this type of conveyor is that it can convey materials vertically.

The bucket conveyor has a proven track record in a variety of fields, including the conveyance of various raw materials, foodstuffs, crushed stones, and fertilizers.

Uses of Bucket Conveyors

Bucket Conveyors are often used in industrial production lines because their structure allows them to convey large quantities of goods at high speed and efficiency. They are particularly suited for conveying amorphous materials such as powders.

Therefore, they are suitable for conveying raw material powders and pellets (granular resins) in chemical plants. They are often used for vertical conveying of rice and flour in food factories. They are also used to transport dried fruits and canned foods.

They are also widely used in the mining industry to transport ore and coal. Bucket Conveyors are needed to transport ore in underground mines and open pit mines. Bucket Conveyors are sometimes used to transport ore before it is transferred to trucks, railcars, or other means of transportation.

In recent years, they are also used in the recycling industry. For example, Bucket Conveyors are used in recycling plants to convey and sort waste materials. The Buckets prevent spillage of conveyed materials and ensure smooth transportation.

Principle of Bucket Conveyors

Bucket Conveyor consists of a belt, bucket, and drive source.

1. Principle of Operation

The belt of a bucket conveyor is often designed to be rotated by a rotating shaft. Power transmission for the belt is typically provided by a three-phase induction motor. As the belt begins to rotate, the buckets are also carried by the belt.

The buckets are attached to the belt at regular intervals, lifting and carrying items as the bucket moves. As the bucket moves, the goods in the bucket are carried with the bucket. Designed for continuous goods transport, the bucket is capable of efficiently conveying large quantities of goods.

When the bucket arrives at its destination, the goods are unloaded from the bucket. At the end of the line, the bucket is unloaded by inverting as the belt is turned over. The bucket is discharged to the next process by means of a chute or other device installed below the belt turnover.

2. Installation Location

The Bucket Conveyor has a hopper attached to the material feeding section, and the materials fed from the previous process are concentrated directly above the bucket by the hopper. Adjacent buckets on the conveyor are connected to each other in the direction of conveyance to avoid gaps between them and prevent the material from falling out of the bucket conveyor.

If the amount of material to be conveyed exceeds the capacity of the Bucket Conveyor, a fixed-feed mechanism such as a rotary feeder is used at the bottom of the hopper.

How to Select a Bucket Conveyor

Bucket Conveyors are selected based on the material to be conveyed, the amount of material to be conveyed, and the environment in which it will be used.

If powder or small particles are to be conveyed, an enclosed Bucket Conveyor should be selected to prevent dust generation. If the destination height or distance is long, a longer Bucket Conveyor should be selected.

Determine the size of the Bucket Conveyor and the capacity of the motor to be installed by ascertaining the volume and speed to be conveyed. It is important to ascertain the volume and speed to be conveyed and select the necessary equipment.

Materials should be selected to match the environment in which they will be used. If the goods to be conveyed are corrosive, select stainless steel or resin. If the material is explosive, a Bucket Conveyor manufactured from a durable material should be selected.