What Is a Deburring Machine?

Deburring machines are used to deburr molded products made of metals and resins.

Molded products are made of metals such as stainless steel, copper, aluminum, iron, and titanium, as well as plastics and other resins that are easily scratched. Since the deburring method differs depending on the material, there are various types of deburring machines. Some types scrub with a brush, types that irradiate pebble-like beads, and types that remove burrs with a laser. Deburring machines with conveyor belts are easy to work with and have a highly efficient structure.

Uses of Deburring Machines

Most products on the market are deburred because burrs occur on molded products made of metal, plastic, and other resins that have undergone cutting, pressing, and injection molding processes. Most of the products sold are deburred. Many factory-produced molded products use deburring machines.

A wide variety of deburring machines are available because deburring is necessary for small parts as well as for large metals such as sheet metal, pipes, and angles. In addition to deburring, deburring machines may also perform oxide film removal and hairline processing at the same time.

Principle of Deburring Machines

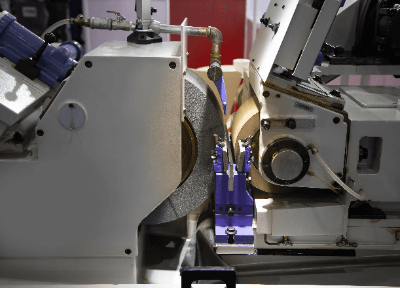

Many types of deburring machines have a rotating brush that removes burrs on the surface, and they are also used for large-formed shapes, such as sheet metal. In this article, we will explain the principle of the brush type.

Brushes made of steel wire, stainless steel wire, brass wire, or other metal materials rotate and polish molded products. In some cases, natural materials such as horsehair, pig hair, or plant fibers are used for the brush. The brushes rotate at high speeds, and many are designed to brush even the smallest parts evenly so there is no unevenness in the removal of burrs.

Depending on the material and shape of the molded product, the length and shape of the brush to be ground and the material of the bristles are adjusted.

Different types of brushes are used: foil brushes are suitable for polishing flat surfaces and deburring edges; end brushes are good for polishing bottoms and corners; condenser brushes can be used for cleaning and deburring fine holes such as screw holes; and miniature brushes are suitable for small parts and jewelry.

Deburring with brushes is not scraping to change dimensions, but it can remove rust and dirt as well as burrs and polish surfaces.