What Is Soldering Equipment?

Soldering equipment refers to tools that utilize solder, an alloy commonly made of tin and lead, to bond metals together. However, in recent years, lead-free solder, mainly comprising tin, silver, and copper, has become prevalent due to health concerns and regulations like the RoHS Directive, which restricts hazardous substances in electrical and electronic equipment.

Types of Soldering Equipment

Various types of soldering equipment are used for different applications:

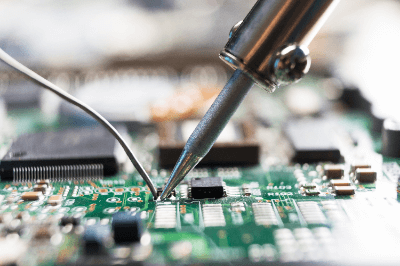

1. Solder with a Soldering Iron

Manual soldering typically involves a soldering iron.

Usage

This method is suitable for small-scale production of electrical components and soldering complex shapes.

2. Flow Soldering

This process involves dipping an entire board into a layer of melted solder.

Usage

It is used in the mass production of electrical components, particularly for soldering electronic components with lead wires onto a board.

3. Reflow Soldering

Solder cream is applied to the board and then melted in a furnace for soldering.

Usage

This method is also used for mass-producing electrical components, where electronic components are placed on the board and then soldered together.

Principle of Soldering Equipment

The principle of soldering involves two key concepts: wetting and capillary action.

1. Wetting

Wetting refers to the blending of molten solder with metal. When solder is applied to metal, its surface tension forms a round shape. The contact angle, the angle between the solder’s tangent line and the metal, indicates the ease of wetting. A smaller contact angle means better wetting, similar to how water spreads on glass.

2. Capillary Phenomenon

Capillary action is the process where molten solder flows into the gap between two metals due to surface tension. For effective soldering, narrowing this gap is crucial.

Moreover, metal surfaces exposed to air typically develop an oxide film, which hinders soldering. Flux, mainly consisting of abietic acid, is used to remove this oxide layer. Flux can be included in the solder or applied separately, and it also cleans the metal surface.