What Is a Digital Tachometer?

A Digital Tachometer is an industrial device that reads and digitally displays the RPM of an engine or motor.

A Digital Tachometer is an industrial device that reads and digitally displays the RPM of an engine or motor.

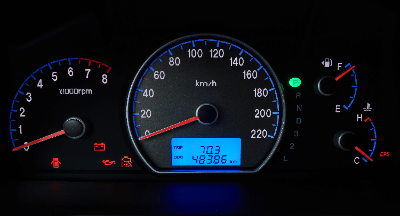

A familiar example is the tachometer installed in automobiles. Automobile tachometers measure the number of revolutions of the engine.

RPM is also a measure of the speed of rotational motion of an object. For example, when an object rotates only N times per minute, the rotational speed is expressed as N.

RPM stands for Revolutions Per Minute. In addition to RPM, it may also be written as min-1, both of which indicate the number of revolutions per minute.

Uses of Digital Tachometers

Digital Tachometers are used for inspection and maintenance of various industrial machines. In some cases, they are constantly measured to monitor the operating conditions of machinery. In the field of research and development, they are also used to measure the RPM of laboratory equipment.

An example in our daily lives is the tachometer in a car. In many cases, not only digital tachometers are used in cars, but also analog tachometers. Analog tachometers are easier to use than digital tachometers.

Digital tachometers are said to be easier to use when maintaining a target speed. On the other hand, analog tachometers are easier to use when adjusting to a target speed. The reason for this is that the speed of the analog needle movement also allows the driver to sense the rate of speed change.

Principle of Digital Tachometers

There are two types of digital tachometers, contact type and non-contact type, each with different principles.

1. Contact Type Digital Tachometer

The contact type digital tachometer measures the number of rotations by directly contacting the rotating shaft of the digital tachometer to the rotating shaft of the object to be measured. There are two methods of contact: contact with the end face of the target rotating shaft or contact with the side face of the rotating shaft.

- Contacting the end face of the rotating shaft

The rotating shaft of the digital tachometer rotates at the same speed as the shaft to be measured, and the measurement value can be read as it is. - Contacting the side surface of the rotating shaft

The rotating shaft of the target and the rotating shaft of the digital tachometer do not rotate at the same RPM. It is necessary to determine the relationship between the ratio of the rotation speeds based on the difference in their respective diameters.

2. Non-Contact Type Digital Tachometer

For non-contact types, there are electromagnetic types and photoelectric types.

- Electromagnetic type

A part of the measuring shaft is magnetized, and the change in the magnetic field when the electromagnetic sensor of the digital tachometer is brought close to the measuring shaft is converted to detect the number of revolutions. - Photoelectric type

A reflective mark is placed on the measuring shaft, red visible light from the digital tachometer is directed toward the reflective mark, and the reflected light is received by the light receiving element and amplified by an amplifier to measure RPM.

Other Information on Digital Tachometers

Cautions for Cutting Machines

Cutting tools such as end mills have a recommended cutting speed. This is the recommended cutting speed for machining a certain material with that tool, and is set according to the type of tool and material to be machined.

From this recommended cutting speed, a calculation using the tool diameter is necessary to set the speed of the machine tool. To obtain the same recommended rotational speed, the smaller the tool diameter, the faster the tool must rotate. In doing so, make sure that the capacity of the machine tool is not exceeded.

Also, when making this calculation, care should be taken with the unit of length. Tool diameter is usually expressed in millimeter as a unit, while cutting speed is expressed in meter/min and machining length per minute in meter.