What Is a Screw Pump?

A Screw Pump is a pump consisting of a screw-shaped rotating body and a cylindrical fixed body.

It is a type of rotary pump in which the rotation of the Screw Pump’s rotating body transfers fluid toward the pump’s discharge outlet. Another name for this pump is a Screw Pump.

Depending on the number of screws, there are 1-axis Screw Pumps, 2-axis Screw Pumps, and 3-axis Screw Pumps.

Applications of Screw Pumps

Screw Pumps are used in a wide variety of applications due to their structural characteristics. In particular, they are widely used in industry because they can pump liquids with high viscosity and liquids containing loose solids. The following are the main applications for Screw Pumps:

1. Food Industry

Screw pumps are used to pump a variety of liquids used in the food industry, including pasty liquids, jams, sauces, and syrups. Screw Pumps can pump liquids without damaging them, thus preserving product quality.

2. Chemical Industry

Screw pumps are used to handle a wide variety of chemicals, such as acids, alkali solutions, and petroleum products. Since they can transfer liquids with high viscosity, they can handle high-viscosity chemicals.

3. Petrochemical Industry

Screw Pumps are used in the petrochemical industry to transfer highly viscous heavy oil. They are also useful for handling high-temperature liquids. Screw Pumps can be operated for long periods of time due to low wear.

4. Agriculture

In the agricultural field, Screw Pumps are used in the livestock and dairy industries. They are used to transfer highly viscous liquids such as milk and liquid fertilizers. Screw Pumps are also used in milking machines due to their self-priming nature.

5. Construction Industry

In construction, Screw Pumps are used in concrete pumps and cement pumps. Screw Pumps have a very wide variety of applications in construction sites because they can pump liquids that contain solids in a gentle manner.

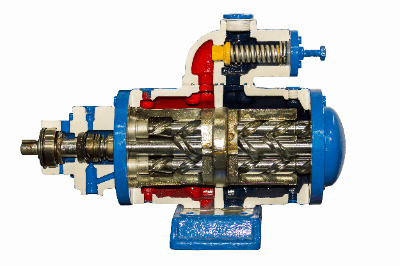

Principle of Screw Pumps

Screw Pumps consist of a fixed cylindrical part (stator) and a rotating spiral part (rotor). As the rotor rotates, the liquid inside the stator is sucked up and transferred to the discharge port according to the spiral shape.

The self-priming force to suck up the liquid inside the pump is so high that the pump can suck up the liquid even when it is not positioned above the liquid. In addition, since the rotating parts do not come in contact with the liquid, there is little wear, and liquids with high viscosity can be handled.

There is a clearance between the rotor and stator, which is carved in a spiral shape, for the liquid to pass through. This clearance is typically very narrow, only a few hundredths of a millimeter. This clearance generates the suction force created by the spiral shape of the rotor and stator and allows the liquid to be sucked up.

Types of Screw Pumps

There are several types of Screw Pumps. The following are examples of Screw Pump types:

1. Single Screw Pump

Single Screw Pumps consist of a single screw (rotor) and stator. The screw has spiral grooves on it to suck up the liquid, and the rotation of the screw pumps the liquid. Single Screw Pumps are mainly used to pump low-pressure fluids.

2. Twin-Screw Pump

Twin Screw Pumps have two screws facing each other. Each screw rotates and moves in opposite directions, pumping liquid toward the discharge port of the pump. They are used to pump high-viscosity liquids.

3. Triaxial Screw Pump

The Triaxial Screw Pump consists of three screws arranged in a concentric circle. Rotation of each screw pumps the fluid toward the center of the pump. Triaxial Screw Pumps are used to handle high viscosity liquids and are commonly used in the petrochemical industry.

4. Vacuum Screw Pump

Vacuum screw pumps use multiple screws to generate vacuum pressure to suck up liquids. They are used for self-priming and vacuuming of liquids.

How to Select a Screw Pump

When selecting a Screw Pump, it is important to understand the characteristics of the target liquid, such as viscosity, density, grain size, and corrosiveness. Depending on the characteristics of the liquid, the screw shape and material, as well as the pump’s rotation speed must be adjusted.

It is also important to select the type that best suits the intended use. For use in the food industry, stainless steel pumps are often selected.

Reliability of the manufacturer is also an essential factor for long-term operation. It is advisable to investigate the manufacturer’s reputation, quality, and support system, and purchase from a reliable manufacturer.