What Is an Automatic Lathe?

An automatic lathe, or a multi-axis automatic lathe, is a machine tool that shapes material by applying a cutting tool to it while it rotates. These lathes are often controlled by CNC (computerized numerical control), enhancing precision and efficiency in the machining process.

Uses of Automatic Lathes

Automatic lathes are indispensable in metalworking manufacturing for cutting bar-shaped materials. They automate the machining process to produce parts with consistent shapes, such as screws and rotary shaft parts. While lathe turning produces chips and swarf, automatic lathes enable efficient mass production by minimizing waste, unlike forging and heading, which require expensive dies.

Principle of Automatic Lathes

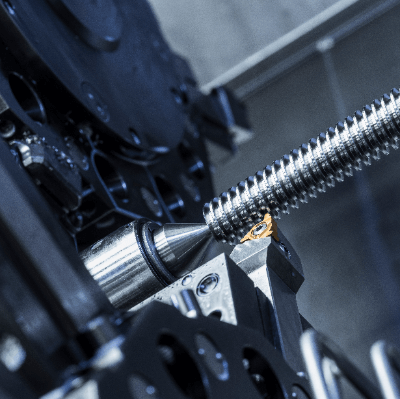

Automatic lathes consist of a cutting process unit and a control unit. The machine secures the material using a chuck, rotates it with a spindle, and applies cutting tools mounted on a tool post. To accommodate various processing types, the tool post can hold multiple tools and automatically switch between them, using mechanisms like combs or turrets for tool change.

The control unit, which is operated through an operation panel, manages the spindle’s rotation speed, tool selection, and tool movement. Operators input machining programs to shape the material into the desired form.

Types of Automatic Lathes

Automatic lathes vary by control method and configuration:

1. Classification by Control Method

They are categorized into CNC automatic lathes, which use computer programs and servo motors, and cam-type automatic lathes, which rely on mechanically produced cams for operation movements.

2. Classification by Machine Configuration

Bar Workpiece Machines: These machines process longer materials by cutting and re-gripping to achieve the desired shape.

Profile Processing Machines: These machines work on pre-cut materials to the required length for single products, processing each by changing grips.

3. Classification by Moving Part

Models differ by whether the spindle head or the tool post moves. The spindle head mobile type uses a guide bush to stabilize the material during machining, reducing material deflection.