What Are Oil Level Gauges?

Oil Level Gauges are a type of device used on ships and tanks to measure the height of the liquid level.

Oil Level Gauges are a type of device used on ships and tanks to measure the height of the liquid level.

It is an indispensable measuring instrument for controlling the quantity and flow rate of liquids, especially when handling petroleum, chemicals, and other liquids.

Since accurate measurement and durability are required, proper selection and maintenance are necessary.

Uses of Oil Level Gauges

Oil Level Gauges are often used on ships, power plants, factories, etc. They accurately measure fuel consumption on ships to determine fuel efficiency and enable efficient navigation. Accurate inventory control is also necessary for cargo oil tanks, and oil level gauges measure the liquid level height to determine the amount of inventory.

Locations of use at power plants include boiler feed water tanks and steam drums. Accurate measurement of coal and crude oil consumption at power plants can improve power generation efficiency. In addition, since a drop in the water level of boiler feed water tanks is directly linked to fire or explosion, the oil level gauge constantly monitors the water level.

Oil Level Gauges are used in factories and tank trucks during the transfer of petroleum products and chemicals. By measuring the liquid level height, risks such as leaks and excessive loading can be identified for safe transportation.

Other applications include hydraulic excavators, forklifts, and hydraulic units.

Principle of Oil Level Gauges

Oil Level Gauges utilize the law of buoyancy. Typically, liquid is injected into a U-shaped tube, and a floating body is placed in the tube. The floating body is subjected to buoyancy force as it floats on the surface of the liquid. This buoyancy causes the floating body to move up and down, and the display needle moves according to the height of the liquid surface.

By determining the volume and density of the floating body, it is possible to accurately display the height of the liquid surface. A scale attached to the inside of the U-shaped tube allows the liquid level height to be checked at a glance.

The material of the oil level gauge varies depending on the type of liquid. For liquids such as petroleum products and alcohol, metal floats are used, while plastic floats are used for liquids such as water.

The temperature and pressure of the liquid to be measured must also be taken into account, and it is important to select the appropriate oil level gauges for accurate measurements.

Types of Oil Level Gauges

There are various types of oil level gauges. Selecting the right oil level gauge for the location and purpose of use will lead to accurate measurements.

The following are some of the types:

1. Booster Gauge

A booster gauge is an oil level gauge that measures the height of the liquid level using the pressure difference. Air pressure is applied to a U-shaped tube filled with liquid, and the pressure difference determines the liquid level height.

This is a widely used oil level gauges because it can accurately measure the level without being affected by the viscosity or density of the liquid.

2. Dipstick Gauge

A dipstick gauge is an oil level gauge that directly measures the height of a liquid by dipping a long stick-shaped instrument (not a U-shaped tube) into the surface of the liquid. Often used on mobile tanks and vessels, dipsticks are available in lengths that can be adjusted to match the height of the tank.

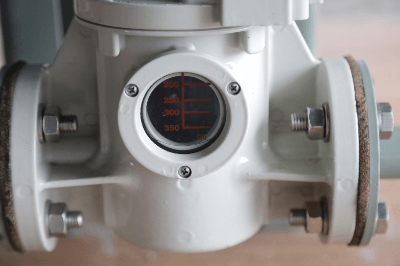

3. Glass Tube Oil Level Gauge

The glass tube oil level gauge is an oil level gauge in which liquid is injected into a transparent glass tube to visually check the level of the liquid. When there is no liquid, the glass part appears white, and when liquid is present, it appears dark because of reflection from the liquid. If the liquid is hydraulic oil, the color of the hydraulic oil is reflected and the level can be checked.

Because of its high accuracy, it is sometimes used for exact measurements of chemicals and pharmaceuticals. However, care should be taken because the glass tube can break.

4. Float Type Oil Level Gauge

The float type oil level gauge is an oil level gauge that uses a float floating on the surface of the liquid to measure the height of the liquid. They are capable of accurate measurement even in areas where liquids move violently, and can be directly attached to tanks. However, the measurement accuracy of float-type oil level gauge may vary depending on the type and shape of the float, so proper selection is necessary.

Products with contact outputs consist of components such as floats, magnets, and reed switches. The float moves up and down under the buoyancy force of the liquid, and the magnet built into the float actuates the reed switch, which produces a contact output.