What Are Membrane Switches?

Membrane Switches are switches that use a sheet of PET film or other thin film as the contact point on a circuit.

Membrane Switches are switches that use a sheet of PET film or other thin film as the contact point on a circuit.

Membrane switches are widely used as buttons for home appliances, inspection equipment, and other devices that require manual switch operation. The switches have contacts on switch circuits inside sheets of thin films. By manually pressing the thin films, the switches are connected. Because the switches are not exposed to the outside air due to its structure, it can be said to be a very dustproof and waterproof switch.

Membrane switches include those that use a disc inside to provide a clicking sensation when the switch is pressed, and those that have letters and numbers printed on a film on the surface.

Uses of Membrane Switches

Membrane switches are widely used for circuitous switch connections in products that require manual pressing of buttons and switches.

Examples include home appliances, electronic devices, inspection equipment, laboratory equipment, and automotive parts. They are also used in many other products around us, such as:

- Input parts for numbers and signs on calculators

- Buttons on household washing machines

- Operation buttons of OA equipment such as copy machines and PC keyboards

When selecting membrane switches, in addition to their dustproof and waterproof characteristics, various specifications required of switches, such as heat resistance, durability, and size, must be considered.

Principle of Membrane Switches

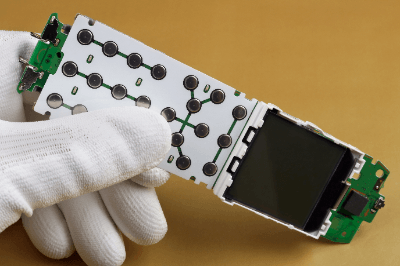

The principle of membrane switches is based on the operation of thin-film mechanical switches, in which the upper contact sheet inside a thin-film surface sheet, such as PET film, is pressed by a finger against the lower contact sheet stacked via a spacer, and the contacts touch each other to energize the switch.

The surface sheet is the part that is actually touched by the users hand and are printed with numbers and letters, and some products are waterproofed. A conductive button is attached to the upper contact sheet, and the components on the lower contact sheet are the button and circuit wiring to match the upper contact sheet.

The spacer is designed to prevent the button on the upper contact sheet from making contact with the button on the lower contact sheet under normal conditions, and has a hole in it to match the button. When the button is pressed, the entire sheet is pushed in and the contacts make contact with each other to energize. The backing sheet is used to bond the membrane switch to the device that uses it.

While this sheet configuration is the basis of a membrane switch, the surface sheet may also serve as the upper contact sheet, or an embossed or metal dome may be used in combination to achieve a clicking sensation.

Types of Membrane Switches

There are so many types of membrane switch constructions to accommodate their versatile and varied applications. The three basic types are as follows:

1. Flat Type

The flat type has a flat surface with no unevenness, making it easy to make it thinner. It has the simplest structure and can be placed freely. However, there is no click feeling when the switch is pressed.

2. Embossed Type

This surface sheet has an embossed surface, which provides a click feeling and stroke when the switch is pressed.

3. Metal Dome Type

A metal plate called a metal dome is incorporated inside the surface sheet to create a mechanical clicking sensation.

Other Information on Membrane Switches

1. Membrane Switches with Built-in LEDs

Membrane switches are structurally multi-layered, so LEDs can be mounted inside to make them easier to visually recognize when the switch is ON or OFF. The membrane sheet is made of transparent PTFE.

Membrane sheets are often made of transparent PET sheets. When multiple functions are to be expressed by using the emission colors of adjacent LEDs, it is necessary to devise the arrangement of LEDs and the internal layer structure to prevent light leakage.

2. Membrane Switches for Automotive Applications

Membrane switches are used in automotive applications and are used in sensor applications to detect occupants.

With the introduction of mandatory seat belt usage for example, automakers have built systems to encourage passengers to fasten their seat belts. Membrane switches are embedded in the seat surface, and the membrane switch is activated by the sinking of the seat surface due to seating.

The presence or absence of the membrane switch makes it possible to detect whether or not a person is sitting in the seat. In many cases, palm-sized membrane switches are used in order to prevent malfunctions caused by uneven seating positions.

3. PC Keyboards

The current primary use of membrane switches is in PC keyboards. Wiring circuits for a variety of switches corresponding to multiple keys are formed in a printing process on a large sheet covering the entire keyboard. Multiple conductive buttons are then attached and energized by pressing the keys.

Membrane switches are now widely used in many PC keyboards because they can easily be made thinner, and are dustproof and waterproof.