What Is a Tantalum Capacitor?

A tantalum capacitor is a type of electrolytic capacitor that uses tantalum oxide as the Dielectric material.

An electrolytic capacitor is a capacitor that uses an oxide film of aluminum or tantalum as a dielectric material. Tantalum capacitors are made by oxidizing the surface of tantalum, a rare metal, to form tantalum pentoxide (Ta2O5), which is then used as the Dielectric material.

Tantalum capacitors are smaller than aluminum electrolytic capacitors. In terms of merits, tantalum capacitors have a longer life, are resistant to temperature changes, and have better frequency characteristics. On the other hand, tantalum capacitor is very expensive, so the price is relatively high for a capacitor.

In addition, there is a risk of short circuit between electrodes when broken. Therefore, it is important to observe proper usage.

Uses of Tantalum Capacitors

Tantalum capacitors have a wide range of applications and are used in all kinds of electronic equipment, including cellular phones, personal computers, video game consoles, car navigation systems, and audio equipment. Because of their superior high-frequency and temperature characteristics compared to aluminum capacitors, tantalum capacitors are used in smoothing circuits for switching power supplies that turn current on and off at high frequencies.

Another ideal application is decoupling capacitors that absorb spike noise in power supply circuits. Furthermore, they are also used as backup capacitors to hold the power supply temporarily.

In recent years, miniaturization has been progressing, and products as small as 0.5 mm in height have appeared, contributing to the miniaturization of cell phones, personal computers, and other devices.

Principle of Tantalum Capacitor

A tantalum capacitor is composed of a chant pole, a dielectric, and a cathode.

1. Anode

Tantalum material is connected to the electrode via a sintered metal rod.

2. Dielectric

A thin film of tantalum pentoxide, which is oxidized from the tantalum of the anode, serves as the dielectric. A kind of diode is formed between the tantalum pentoxide and the cathode, which has capacitance when the reverse bias is maintained, but large current flow when a forward voltage is applied.

This is the reason why tantalum capacitors have polarity. The extremely thin layer of tantalum pentoxide allows for a large capacitance.

3. Cathode

Manganese dioxide or a conductive polymer is used as the cathode material to ensure continuity between the electrodes. Conductive polymers have lower resistance and better ESR characteristics than manganese dioxide.

In addition, a current-carrying metal such as silver or graphite is placed between the cathode and the electrode to lower the resistance. Aluminum electrolytic capacitors use an electrolytic solution, which gradually evaporates and has a relatively short life span. Tantalum capacitors, on the other hand, are made entirely of solid material and have a long life span.

Other Information on Tantalum Capacitors

1. Precautions for Use

The main cause of failure in tantalum capacitors is due to a localized short circuit in the dielectric of the capacitor. When connected to a low impedance circuit such as a power line, a large current will concentrate at the shorted point and generate heat, which may lead to ignition.

Once a tantalum capacitor ignites, it continues to burn with a flame Until it burns out. For this reason, many manufacturers of equipment requiring high reliability or equipment that is constantly energized, have banned the use of tantalum capacitors altogether. Even in portable equipment powered by batteries, burnout of tantalum capacitors has been reported, so care and circuit verification are required when using them.

Two general countermeasures are “do not apply reverse voltage under any circumstances” and “select a capacitor with a rated voltage that has a sufficient margin for the voltage applied to the capacitor.” In particular, when used in a power supply circuit, it is desirable to use a tantalum capacitor with a voltage rating of at least twice the power supply voltage, or three times the voltage rating, if possible.

In addition, if the ripple current inflow is large, the heat generated inside the capacitor may cause degradation, so it is also recommended to select a large package that is conducive for heat dissipation.

2. Polarity Indication of Tantalum Capacitor

Tantalum capacitors are polarized, and if the specified polarity is incorrect, a large current will flow, leading to ignition in the worst case. Therefore, it is necessary to understand the polarity markings on the electrodes.

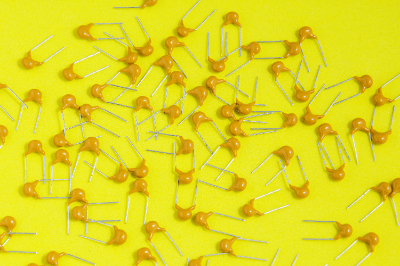

Tantalum capacitors can be classified into three types based on their construction, namely: chip type, metal case hermetically sealed type, and resin dipped type.

- Chip Type

A white band is printed on the top surface of the black molded case with the capacitance and rated voltage, while the electrode below the band is the anode. - Metal Case Hermetic Seal Type

For applications requiring high reliability, a + sign is printed on the surface of the round cylindrical shape, along with capacitance, rated voltage, etc. The lead wire on the side near the + sign is the anode while the lead wire on the side near the – sign is the cathode. - Resin Dip Type

It is vertically structured. The + sign is printed on the resin surface along with capacitance, rated voltage, etc. The lead wire on the side near the + sign is the anode while the lead wire on the side near the – sign is the cathode. The lead wires are unequal in length, with the lead wire on the cathode side being shorter.

Aluminum electrolytic capacitors, which are also polarized, are marked on the anode side and are marked differently from tantalum capacitors. When replacing an aluminum electrolytic capacitor with a tantalum capacitor, care must be taken to ensure that the polarity is correct.