What Is a Laser Module?

A laser module is a set of devices that produce a laser light source, which is required for various devices that operate using lasers.

A laser module is a set of devices that produce a laser light source, which is required for various devices that operate using lasers.

Today, there are many devices that use lasers, and in particular, laser light sources are indispensable for measurement devices, position detection devices, and various sensors. Most lasers used for measurement purposes are blue, green, or red lasers in the visible light range, but there are also lasers used for processing purposes that deviate from that wavelength range, and they are classified from Class 1 to Class 4 according to the degree of danger they pose.

Uses of Laser Modules

Applications of laser modules vary depending on the wavelength, but in general, they are used for measurement purposes, pointers, light sources for DVD pickups, wiring of semiconductor parts, and mark printing on resin materials and other materials.

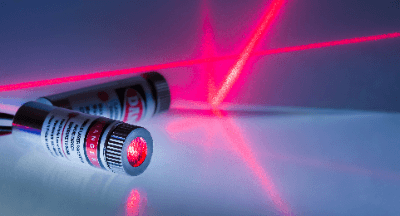

Red lasers are mainly used in measuring instruments, such as microscopes and interferometers. For this reason, many laser modules that can stably emit red lasers for measurement equipment are now commercially available. Light sources in the visible light range are relatively safe as long as they are not greatly amplified, so they are also used in laser pointers and projectors.

On the other hand, lasers of various wavelengths are used in laser processing machines. Depending on the wavelength, the materials that can be processed and the damage to the workpiece will vary.

Principle of Laser Modules

The principle of the laser module lies in the use of elements suitable for the wavelength and phase of the laser light required, and in the utilization of the physical transition of energy levels of the elements, called induced emission.

To obtain light of a specific wavelength, a medium composed of an element is prepared. When this element lowers its level from the excited state, it emits a certain amount of electromagnetic energy, and a light source with a wavelength corresponding to that energy is obtained.

In order to align the phases of this light source in the laser module, it is necessary to drop the levels of many excited elements at once. This is done by using a physical phenomenon called induced emission. Induced emission is a phenomenon in which, when light equivalent to the energy difference between the excited level and the defined level of the element is incident, the electrons in that area also emit energy in response to the incident light. This phenomenon will result in light of the same phase.

In order to perform many induced emissions at the same time, the laser module is configured to extract a laser light source of a certain wavelength by repeating the cycle of excitation of the entire element to an excited state at once and induced emission.

Other Information on Laser Modules

1. Class Classification of Laser Light Sources

Laser light sources are classified according to their safety management, and are classified according to the stage from Class 1 to Class 4. For example, Class 1 is not a safety issue and no special measures are required, but Class 4 is a high power laser that handles CW of 0.5W or more, and there are concerns about burns and damage to the skin and eyes, even if the light is reflected.

Adequate safety measures, including protective equipment, are required, and products are usually labeled with a warning label corresponding to the laser class. Some products are equipped with protective covers, including interlocks, so that even Class 4 lasers can be handled as Class 1 lasers.

2. Examples of Laser Module Wavelengths

Laser modules are commercialized in a variety of wavelength values. Visible light is handled with a lower limit of purple around 380 nm and red around 780 nm, depending on the application, and red lasers are widely used for pointer applications and measuring instruments.

On the other hand, a typical example of a laser source for processing applications is the CO2 laser, which has the longest wavelengths of 10.6um and 9.6um.