What Is ASIC?

ASIC stands for “Application Specific Integrated Circuit.” It is an integrated circuit or microchip that’s been created specifically for a particular application, such as high-speed processing of communications and images. As the “Application-Specific” label implies this hardware solution is a custom-built piece of electronics that’s tailor-made to satisfy a specific purpose.

The advantages of ASIC include high performance, compactness, and cost reduction in manufacturing. By prototyping those application-specific features early in the design process, individual needs are addressed with great effectiveness. However, compared to FPGAs, ASIC systems have the disadvantage of requiring a longer development period. There are also higher development costs to offset due to an inability to rewrite system software and circuits. After all, FPGAs are programmable, but ASIC circuits don’t incorporate this degree of flexibility. Even so, ASIC circuits are ideal for high production runs, and, since large production lines are common, so are ASICs. One example of this line of thinking is a newly minted mobile phone. The hardware has been prototyped and passed through numerous design runs, so no reprogramming work is anticipated.

Uses of ASICs

ASICs are used in a wide range of applications, including home appliances, well-known consumer devices (mobile phones), communications equipment, image processing systems, industrial equipment, and computers.

- High-speed processing ICs for high-speed Internet communications in routers

- High-speed processing ICs for high-quality, high-resolution images in digital cameras

- Newly emerging wearable technology, including processor-intensive VR headsets

- Multimedia equipment for the demanding consumer market. Including tablets and HDTVs.

ASICs have high performance and low unit cost because they are specialized for specific functions. However, it is necessary to consider whether the initial costs required for the development period and design prototyping can be recovered.

Principles of ASICs

Since semi-custom-designed ASICs are generally used, the following introduces the principles of gate-array and cell-based ASICs.

1. Gate Array Type ASICs

Gate-array ASICs use existing silicon wafers as far as the interconnect stage process in the semiconductor manufacturing process and customize the interconnects according to the application in the interconnect process. Since only the wiring circuit layout is designed during development, this method can reduce development costs and time.

2. Cell-Based ASICs

Cell-based ASICs utilize a tailored methodology to accommodate the circuits in ICs at all stages of the masking process. This includes the customized integration of transistor elements, resistors, and capacitors in the semiconductor manufacturing process. Design optimization is possible, allowing for a very high degree of freedom and creating ASICs with good performance. However, the cost and time required for development are higher than those of the gate array type.

Other Information on ASICs

ASIC mining refers to the use of ASICs for crypto assets (formerly known as virtual currency.) In the world of crypto assets, a process called mining (excavation) is required to secure every crypto asset transaction.

Mining uses hash functions to search for different values, and mining is successful when a particular value is met. The sequence of calculations is enormous, and only a successful mining operation can authorize the transaction of a cryptographic asset. ASIC mining is used for these mathematically intensive calculations.

1. Requirements for ASIC Miners

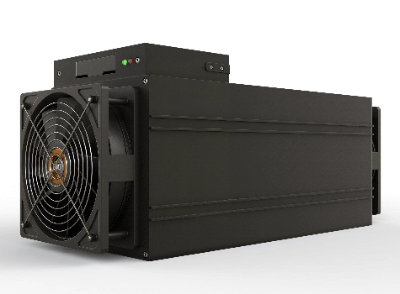

Devices equipped with dedicated ASICs, in which the algorithms for executing hash functions are compiled into circuits or IC chips, are called ASIC miners. The ASIC mining process requires an enormous amount of arithmetic processing, which is also referred to as hash power.

The power required to support this hash power is a topic of much debate around the world in the context of recent environmental issues. Therefore, there are high expectations for further improvements in the high-speed computing characteristics, smaller size, and lower power consumption of ASICs.

2. Development Period and Cost of ASICs

The development period for ASICs is generally longer than FPGAs and processors. The reason for this is that integrated circuits need to be designed individually for each specialized application, and circuits and layouts cannot be modified after masks are issued. The most important factors affecting development time and man-hours are the number of prototypes and the optimization of characteristics.

However, the advantage of ASIC chips over FPGAs is that they have superior characteristics and lower manufacturing costs compared to FPGAs since ASICS are designed specifically for particular functions.