What Is a Membrane Filter?

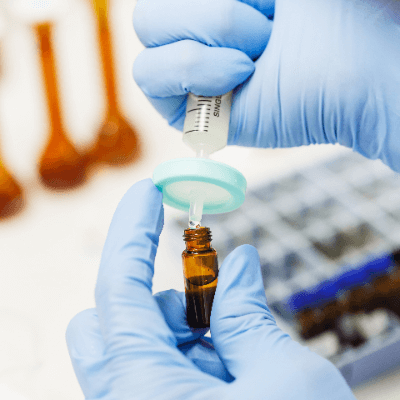

Membrane filters are used to remove fine particles from solutions. Filtration using a membrane filter, also called microfiltration, can reliably remove particles larger than the pore size of the filter. However, membrane filters are prone to clogging, so rough filtration using a pre-filter is often performed before filtration.

Membrane filters are made of a wide variety of materials, including PTFE, PVDF, PES, cellulose mixed ester, and polypropylene. When using a membrane filter, it is necessary to select an appropriate membrane filter based on the chemical resistance of the filtering material, whether or not the components in the sample are adsorbed by the filter material, and whether or not the pore size of the filter is small enough for the particulates to be removed.

Membrane Filter Applications

Membrane filters are made of membranes. Liquid filtration is routinely used in a variety of industries, including food and beverage, medical, electronics, chemical, and textile industries. Membrane filters are used in a process called microfiltration.

Microfiltration is a process that completely traps substances larger than the pore size (pore diameter) of the membrane, enabling stable removal of impurities from liquids. For this reason, microfiltration using membrane filters is used in the semiconductor industry, where even the smallest amount of foreign matter is unacceptable, and before filling, products are sold as solutions.

Material of Membrane Filters

Membrane filters are made of a wide variety of materials. Examples of materials include PTFE (polytetrafluoroethylene), PVDF (polyvinylidene fluoride), PES (polyethersulfone), nylon, cellulose blend esters, and polypropylene.

All of these polymers vary in their resistance to organic solvents, acids, and bases and have very different chemical structures. Therefore, in addition to considering the durability of the solution to be filtered, the ease of sample adsorption on the membrane filter must also be taken into consideration.

Structure of Membrane Filter

Membrane filters can be compared to pre-filters. These are the same “filter” but have a different internal structure and particle trapping mechanism. Prefilters also called depth filters, are made of glass or other fibrous materials that are pressed together. Therefore, the size of the flow path inside the filter is not constant. Also, during filtration, large particles are trapped by clogging in the middle of the flow path. However, if an excessive amount of material flows through the filter, the clogged particles may be pushed out and pass through the filter.

Membrane filters, on the other hand, have a specified maximum pore diameter, and no flow path can be larger than the pore diameter in the catalog. Therefore, particles larger than the pore diameter are captured on the filter surface and completely separated from the filtrate. However, since all particles accumulate on the filter surface, membrane filters are prone to clogging. In actual processes, filtration is often performed first with a pre-filter for simple filtration and then with a membrane filter.