What Is a Thrust Ball Bearing?

Thrust Ball Bearings are bearings that can rotate smoothly while sustaining axial loads, which are loads in the same direction as the length of the rotating shaft.

Thrust Ball Bearings are bearings that can rotate smoothly while sustaining axial loads, which are loads in the same direction as the length of the rotating shaft.

Because they are specialized to carry axial loads, they cannot carry radial loads acting in a direction perpendicular to the axial load. Although axial load is sometimes referred to as thrust load, both terms are used with the same meaning.

Uses of Thrust Ball Bearings

Thrust Ball Bearings can support high axial loads and are used in a wide range of applications, from household machinery to industrial machinery.

In familiar applications, thrust ball bearings are used in home appliances such as refrigerators, vacuum cleaners, printers and peripheral equipment, and fishing reels.

In industrial machinery, they are often used in the main spindles of machine tools such as CNC lathes, milling machines, and machining centers.

When a CNC lathe or similar machine drills the center of a workpiece, the spindle is subjected to a high load in the thrust direction.

The impact and load from machining can affect machining accuracy, but thrust ball bearings can be assembled to minimize the axial displacement of the spindle.

Principle of Thrust Ball Bearing

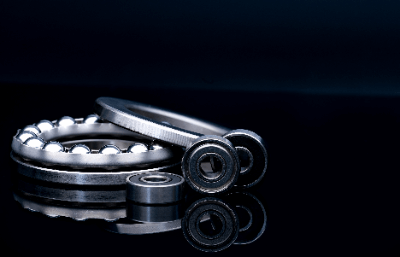

Thrust Ball Bearings consist of three major parts. These are metal balls called rolling elements, a cage that prevents the rolling elements from rubbing against each other, and a raceway. The raceway is a washer-shaped part with grooves in which the rolling elements roll.

To ensure smooth rotation under high loads, the rolling elements and raceways are made of heat-treated ferrous alloy steel. Some of them use ceramic rolling elements.

They are also finished to have a smaller surface roughness. Uniformity of size between rolling elements, etc. is also very important.

Depending on the conditions of use, appropriate lubricant may be required in some cases. Lubricating oil reduces frictional resistance and also plays a role in cooling the bearing when it is used under high loads and rotating at high speeds, which generates heat.

Types of Thrust Ball Bearings

Thrust Ball Bearings are broadly divided into two types: Single Thrust Ball Bearings and Double Thrust Ball Bearings.

1. Single Thrust Ball Bearing

This type consists of a single row of rolling elements and two raceways that sandwich the rolling elements above and below. Single Thrust Ball Bearings support loads in only one direction.

2.Double Thrust Ball Bearing

This type has two rows of rolling elements and consists of three raceways. Double-Type Thrust Ball Bearing can support loads in both directions. However, the increased thickness requires more space for assembly.

3. Other Thrust Ball Bearings

There are two types of thrust ball bearings, called “Aligning type” and “With aligning washers”, for both single and double types.

Aligning Seat Type

Aligning type bearings have a spherical raceway mounting seat. By attaching it to a spherically machined mating part, the position of the raceway is automatically held at the position of the center axis of rotation. This has the effect of suppressing misalignment of the rotating orbit.

With alignment washers

Aligning washers are added to spherically machined raceways. Thrust Ball Bearing with Aligning Washers can be used without spherical machining on the mounting surface of the mating parts to which the thrust ball bearing is mounted. However, more space is required.

Other Information on Thrust Ball Bearings

Precautions for Using Thrust Ball Bearings

When installing a bearing, it is important to carefully consider how the load is applied to the shaft and how it is best supported, and then select a bearing that is suitable for the application and purpose. It is also important to ensure that the mounting surfaces of the raceway and thrust ball bearing are sufficiently rigid to support the loads to be supported, to prevent problems with the bearings.

Lubrication should also be taken into consideration when the bearing is used under high load and high RPM conditions. Lubricant not only reduces frictional resistance, but also cools the heated thrust ball bearing.