What Is a Butterfly Valve?

A Butterfly Valve is a valve with a disk-shaped valve disc that rotates to control the opening and closing of the valve.

A Butterfly Valve is a valve with a disk-shaped valve disc that rotates to control the opening and closing of the valve.

Butterfly valves are called “Butterfly Valves” because the shape of the valve disc resembles a butterfly. The valve can be used in small to large bore sizes, and if the valve interior is lined with PFA or other material, it can be used with corrosive fluids.

Also, compared to ball valves, the flow rate can be adjusted, and the pressure drop is lower than that of globe valves. However, they are difficult to use with high-pressure fluids.

Because they are easy to operate and inexpensive, butterfly valves are used in a wide variety of locations.

Uses of Butterfly Valves

Butterfly Valves are widely used in factory and plant piping, both manual and automatic. Butterfly Valves are not often seen in everyday life, but they are sometimes used upstream in water piping.

They are easy to operate, easy to open and close, and have a short face to face distance, so they can save space even in large bore sizes. For this reason, butterfly valves are often used in large bore locations upstream of transfer piping.

While general flow control valves have a large pressure drop even when fully open, Butterfly Valves have a small pressure drop and can adjust the flow rate to some extent. For this reason, butterfly valves are sometimes used as flow control valves.

Principle of Butterfly Valve

Butterfly Valve consists of a stem, a seat, and a plug. The stem is connected to a handle or other device, which moves the connected valve plug. The Butterfly Valve has a disk-shaped plug, which opens and closes by turning it 90° to close the seat. Compared to ball valves, butterfly valves feature low opening and closing torque and adjustable flow rate even in large bore valves.

Butterfly Valves used to be recognized as valves with low airtightness and prone to leakage. In recent years, EPDM and PTFE have been used for the seat material of the valve plug to ensure airtightness.

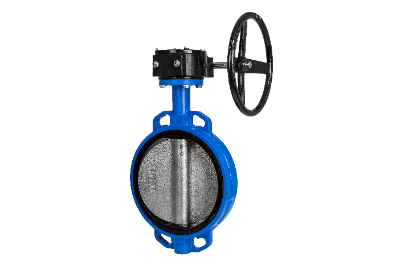

Butterfly Valve Opening/Closing Method (Gear Type, Lever Type)

To open and close the Butterfly Valve, an actuator must be attached to the end of the stem. A lever or gear is attached to the actuator.

1. Lever Type

A lever is used to open and close the Butterfly Valve. This is mainly employed for manual operation. The movement of the lever is synchronized with the movement of the shaft of the Butterfly Valve, and the valve is opened and closed by turning the lever 90 degrees.

It is simple to operate and the degree of opening can be easily visualized. However, the opening/closing operation becomes heavy for valves with large diameters. Because of the danger of unintentional contact with the lever that may change the degree of opening, the lever may be removed except during the open/close operation.

2. Gear Type

The opening and closing of Butterfly Valve is performed by gears. This type is mainly used for large-diameter valves. It may be motorized by a motor. In the gear type, a gear inside the actuator increases torque to move the stem. The large torque required for opening and closing is made possible with a small amount of force.

While the lever type requires only a 90-degree turn, the gear type requires multiple turns to open and close. Also, if left unattended for a long period of time, the gears may stick and fail to open or close.

In addition to the above, compressed air type actuators are also available and should be selected according to the application.

Other Information on Butterfly Valves

Wafer Type Butterfly Valve

Butterfly Valves and other valves can be connected to piping by flange, wafer, threaded, or welded connections. Wafer type valves are also called flangeless type valves and are connected by flanges on both sides of the valve.

The wafer type does not require a flange, making it compact, lightweight, and economically advantageous. In addition, the short distance between the faces enables installation in narrow spaces. It must be sandwiched between flanges on both sides and stud bolts are used.

Stud bolts are bolts that are threaded on both sides and are fastened by tightening nuts from both sides of the bolt. However, in emergency situations, stud bolts may be substituted with inch-cut bolts.