What Is a Check Valve?

A Check Valve is a valve that controls the flow of fluid in a pipe in one direction only and prevents flow in the opposite direction.

Synonyms include Non-Return Valve, One-way Valve, Reflux Valve, Pressure Retention Valve, and Back-Flow Prevention Valve.

Uses of Check Valve

A Check Valve is used when you do not want fluid to flow backward.

The basic uses of Check Valves are as follows:

- Prevention of mixing of two fluids

- Preventing backflow

- Controlling flow direction

- Preventing water hammer

When installed at a point where two fluids merge, the check valve prevents the mixing of the two fluids and controls the flow of only one of them.

When installed in a rising piping section on the discharge side of a pump, fluid flows while the pump is running, and after the pump is stopped, the Check Valve closes to prevent fluid in the piping at a higher level downstream of the pump from flowing back to the pump.

In steam piping, it is also used to prevent water hammer. Water hammer is a phenomenon in which the pressure in a piping temporarily rises and falls due to a sudden change in fluid velocity. The pressure fluctuations caused by water hammer can damage pumps and piping, and Check Valves are used as a preventive measure.

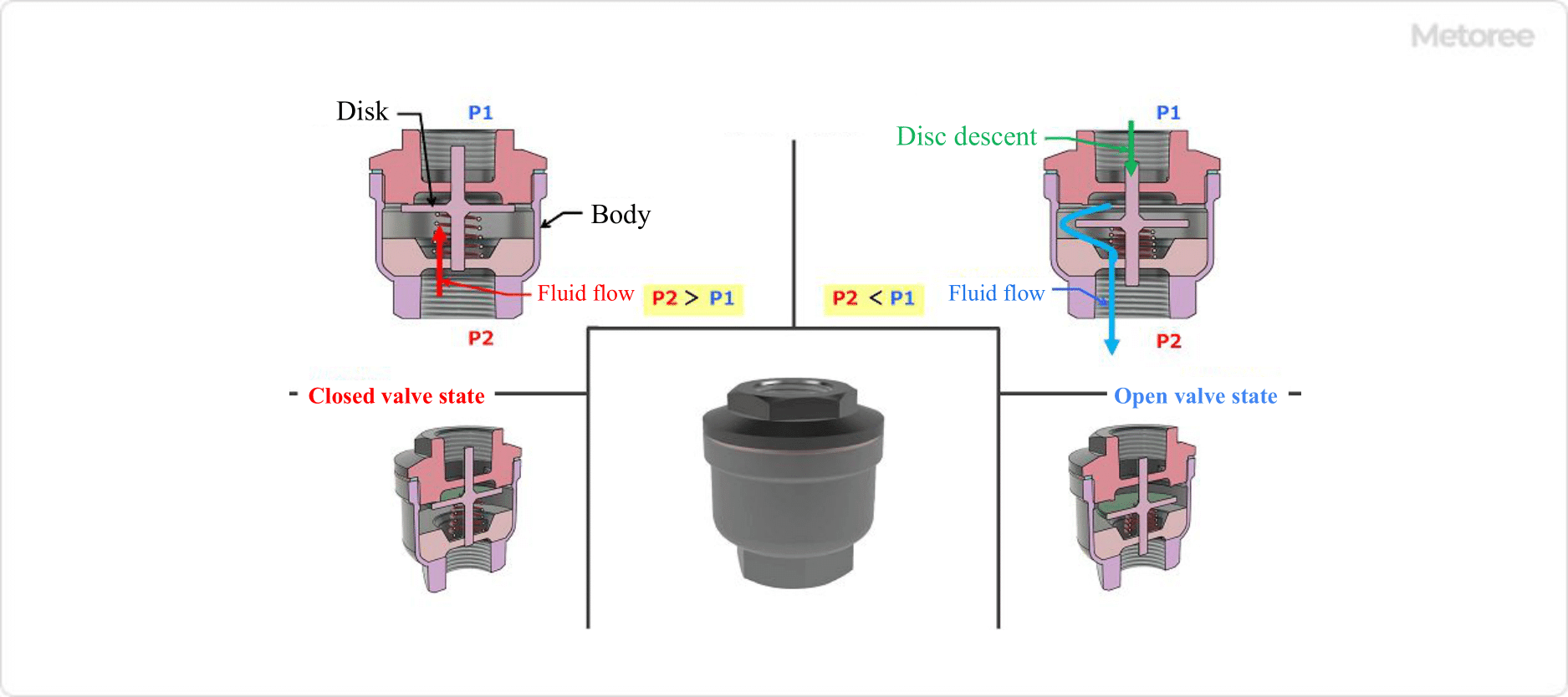

Principle of Check Valve

In a Check Valve, the valve disc is actuated to open and close by the pressure difference between the inlet side (primary side P1) and the outlet side (secondary side P2) of the fluid.

The pressure difference and valve operation are as follows:

Open: Inlet side (primary side P1) pressure is higher than outlet side (secondary side P2) P1 > P2

Closed: Inlet side (primary side P1) pressure is lower than outlet side (secondary side P2) P1 < P2

When the pressure at the outlet side (secondary side P2) is higher, the disc is pressed against the seat surface by back pressure and adheres tightly to prevent fluid backflow. The disc automatically opens and closes according to this pressure difference, and the fluid flows or does not flow.

Types of Check Valves

There are five types of Check Valves. The features of each are as follows:

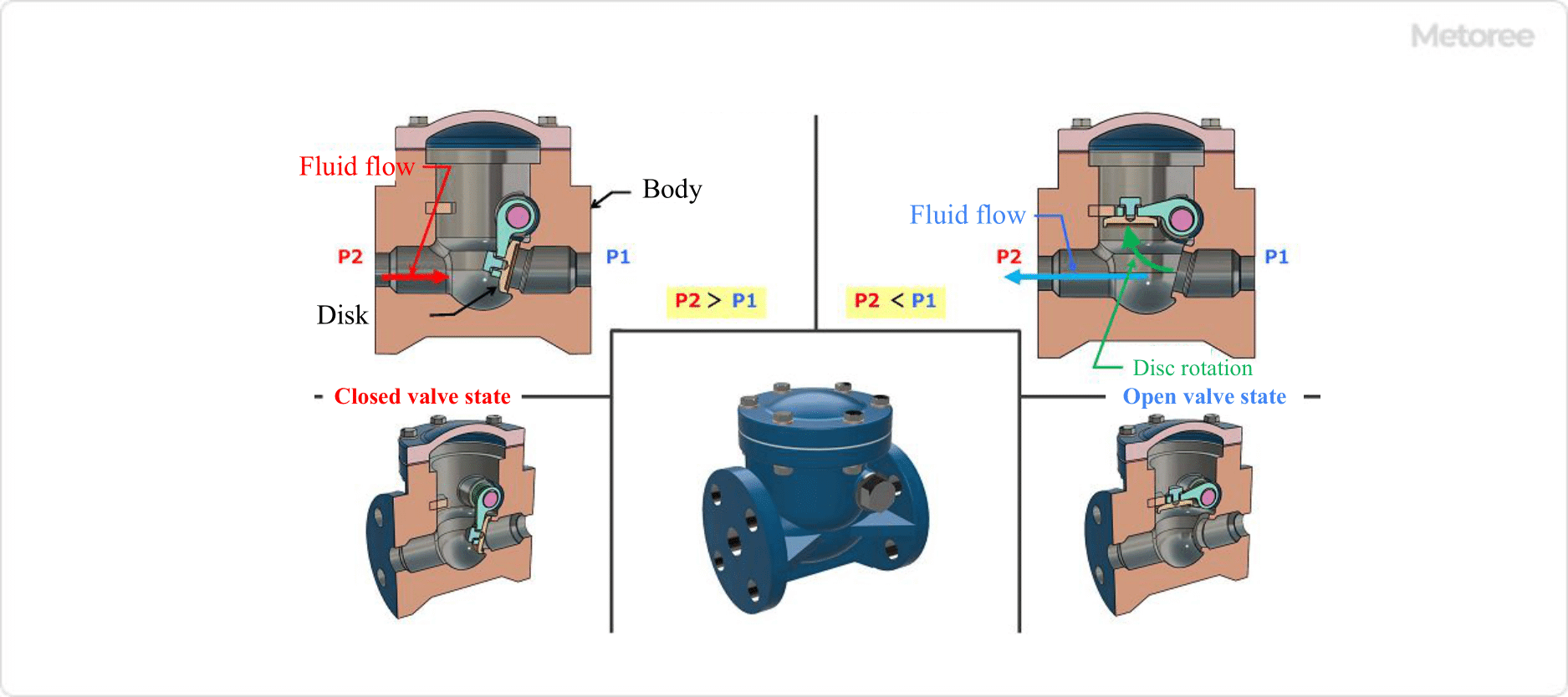

1. Swing Check Valve

Swing check valves have a straight fluid flow and are mounted directly on an arm or disc with the disc attached to a hinge mechanism. The disc rotates with the hinge as a fulcrum and opens or closes the valve according to the pressure difference of the fluid.

Figure 1. Swing check valve

Features

- Generally, when the disc is fully opened at the full port, the disc does not block the flow path and the pressure loss is small.

- Full port means that the flow path of the valve body is the same diameter or larger than the inside diameter of the piping.

- When the disc weight is heavy, the minimum pressure differential for valve opening and the cracking pressure will be large. For lighter discs, the minimum pressure difference to open the valve and the cracking pressure will be smaller.

- Cracking pressure is the pressure difference for a given flow rate.

- Since the disc rotates on a hinge shaft, the shaft and bearing side will wear out due to long-term use and frequent operation. This can result in poor opening and closing action of the disc and reduced sealing between the disc and the seat.

- Since the disc rotates at a relatively large angle from fully closed to fully open, its response to sudden pressure changes is low. Heavy discs also have the problem of greater impact on the seat during abrupt valve closure.

Installation

When the piping is horizontal, or when the piping is vertical, it is used when the fluid flows from downward to upward. It cannot be used when the fluid flows from upward to downward.

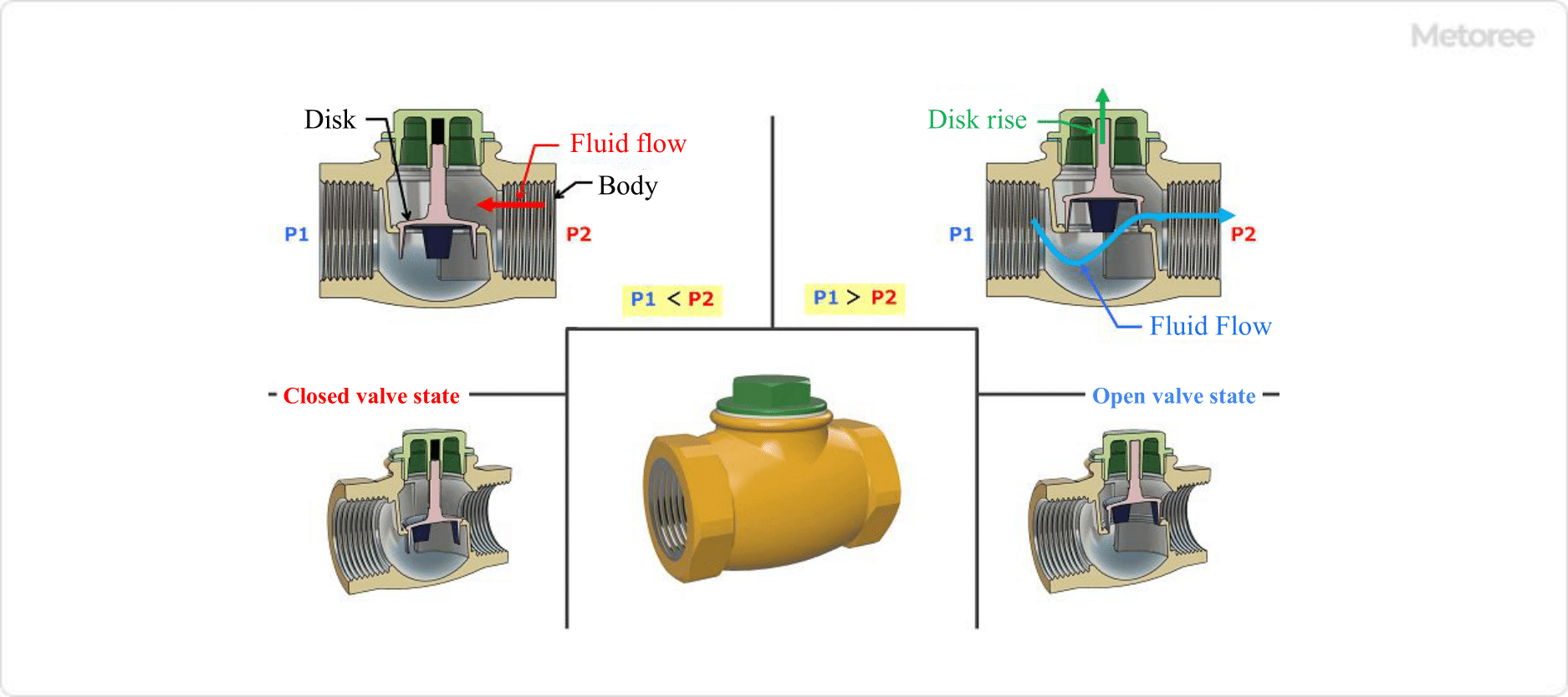

2. Lift Check Valve

The lift check valve is a mechanism in which the fluid flow is S-shaped and the disc to which the shaft is attached rises and falls. The disc rises or descends depending on the pressure difference, and opens or closes the valve.

Figure 2. Lift check valve

Features

- The flow path is S-shaped and pressure loss is high.

- Due to the heavy weight of the disc, the minimum pressure differential for valve opening and the cracking pressure are large.

Installation

Limited to grounding only when piping is horizontal. Cannot be used when piping is vertical and fluid flows vertically.

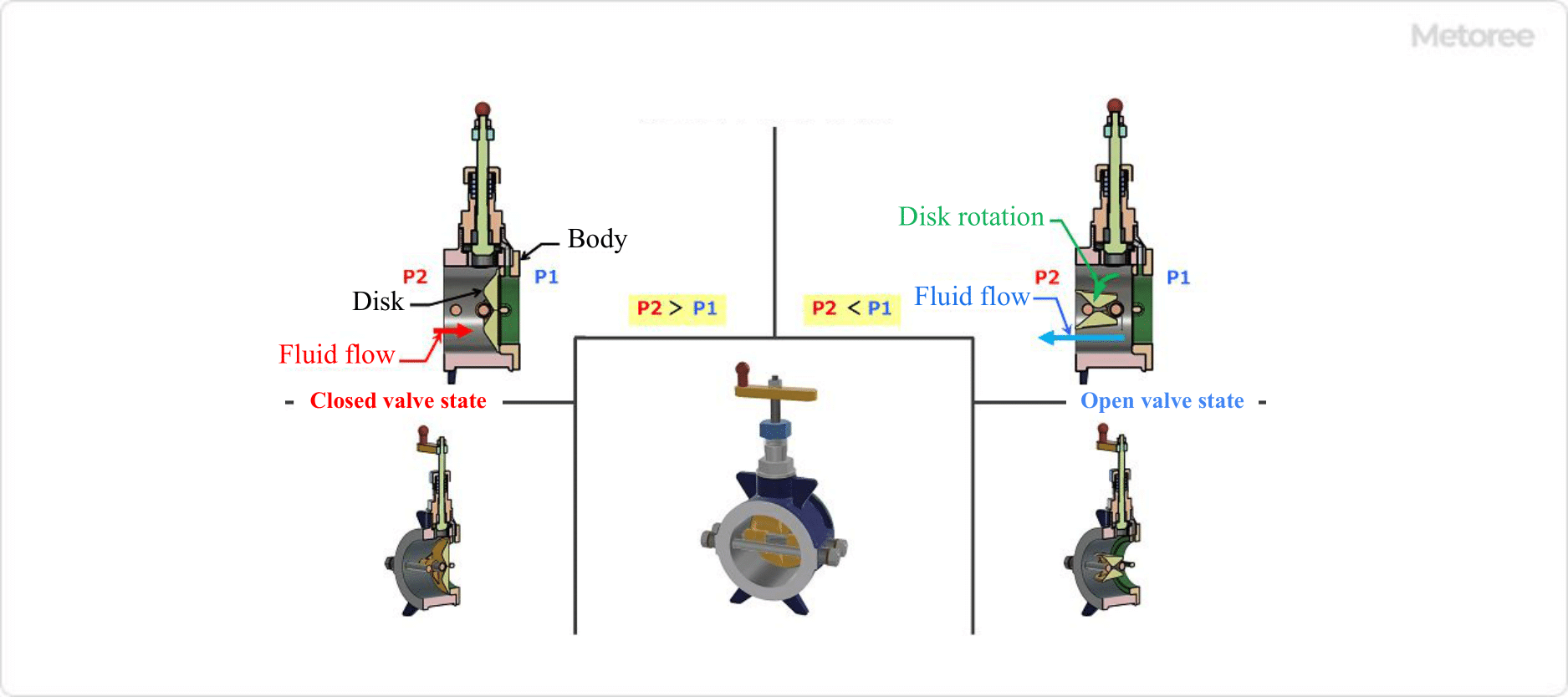

3. Wafer Check Valve

Wafer check valves are wafer-shaped valves that are installed by sandwiching the valve body between flanges and tightening bolts and nuts. The fluid flow is nearly linear and incorporates two semi-circular discs with a hinge mechanism.

The two discs rotate to open the valve due to the difference in fluid pressure using the hinge as a fulcrum, and rotate in the opposite direction to close the valve due to the coil spring attached to the discs.

Figure 3. Wafer check valve

Features

- The flow path is almost straight and the pressure loss is small.

- Wafer-shaped body is thin and lightweight.

- Can be directly attached to pumps and other equipment.

- The disc is forced to rotate by a spring and immediately closes, thus reducing water hammer phenomenon.

- It has high sealing performance with high hermeticity.

- It may be somewhat less responsive and less durable to cavitation and unbalanced fluid flow.

- Some have a built-in bypass channel, eliminating the need to drain residual fluid or install bypass piping for priming.

Installation

Piping can be used in a variety of orientations, including horizontal, vertical, and inclined. When the piping is vertical, the fluid can be used in either vertical or horizontal flow direction.

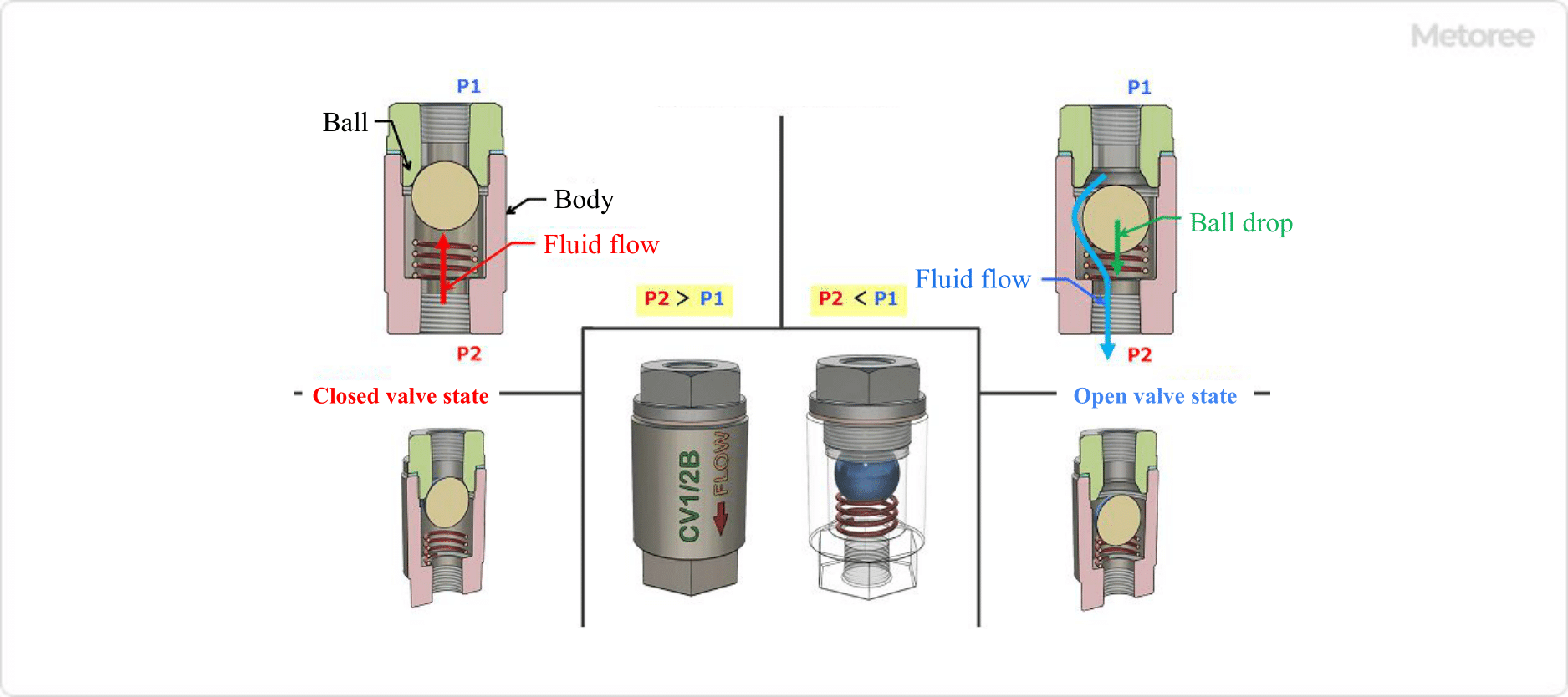

4. Ball Check Valve

The ball check valve is a mechanism in which the fluid flow is S-shaped and the ball of the valve plug rises and falls. The ball rises and falls depending on the pressure difference to open or close the valve.

Figure 4. Ball check valve

Features

- The flow path is S-shaped or straight, and pressure loss is not so large.

- Since the disc motion is unrestrained, some foreign matter in the fluid is tolerated.

- Not effective in preventing water hammer.

Installation

Piping is available for horizontal and vertical applications. The vertical version opens and closes under the ball’s own weight, so it cannot be used when fluid flows from below to above.

5. Spring Disk Check Valve

The spring disc check valve is a mechanism in which the fluid flow goes around the disc in an S-shape and the disc to which the shaft is attached rises and falls. The disc rises due to the pressure difference and descends by spring force to open or close the valve.

Figure 5. Spring disk check valve

Features

- The flow path is S-shaped and flows around the disc, resulting in a large pressure drop.

- The disc is lightweight, and the minimum pressure differential for valve opening and the cracking pressure are small.

- The operating distance between fully open and fully closed is small, resulting in excellent responsiveness.

Installation

Piping can be used in either horizontal or vertical direction. When the piping is vertical, the fluid can be used in either vertical or horizontal flow direction.