What Is a Swivel Joint?

A swivel joint is a piping joint for supplying water, air, oil, or other fluids to a machine part that performs rotary motion or linear motion in the vertical, horizontal, or forward/backward directions.

A swivel joint is a piping joint for supplying water, air, oil, or other fluids to a machine part that performs rotary motion or linear motion in the vertical, horizontal, or forward/backward directions.

A rotary joint is a similar mechanism. Generally, rotary joints are fittings for continuous rotation and are used for piping in machinery that rotates at high speed, such as the spindle of a machine tool.

Swivel joints, on the other hand, often have a fixed upper limit to the angle at which they can be swiveled, and are installed in machinery that rotates at an angle within a fixed range.

Uses of Swivel Joints

Swivel joints are commonly used in machine tools and construction machinery. For example, a swivel joint is used to supply low-pressure or high-pressure fluid to a slide that moves in a straight line in three directions (X, Y, and Z) within a machine. The angle of the joint changes as it moves, eliminating obstructions to the smooth movement of the slide section.

A movable pipeline consists of several swivel joints and pipes. They are used with a defined range of motion and have applications in iron rolling mills, hot presses, tire presses, die-casting machines, injection molding machines, etc.

Swivel joints are used for hose reels, which can handle low rotational speeds to the extent that they are rotated manually.

In automobiles, they are often used for speedometers, tank lorries, and crane trucks. Swivel joints are sometimes used not only for mechanical equipment but also for piping in buildings with seismic isolation structures.

Principle of Swivel Joint

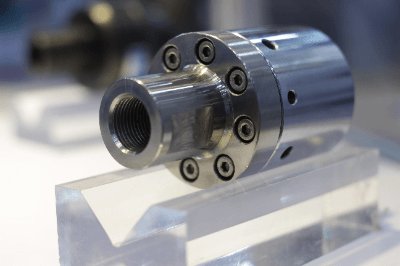

As a rotating mechanism, a steel ball or bearing is built into the shaft of a swivel joint. To maintain smooth rotation, the swivel joint is generally supplied with a certain amount of grease periodically through a grease nipple.

The space between the shaft and the body is sealed with a packing to prevent fluid leakage. Since higher sealing performance is required for use with high-pressure fluids, types that employ a double-seal system are the mainstream.

The advantage of swivel joints is that the rotating mechanism allows the piping to move freely. On the other hand, it has the disadvantage of weakening the strength of the joint itself due to its split structure, which is divided into a shaft section and a main body. Since the rotating part is subjected to thrust radial loads and moment loads, it must be designed to have sufficient strength.

Other Information on Swivel Joints

1. Swivel Joints Used in Cranes

Swivel joints used for pumping lines of moving parts are also used in heavy machinery such as cranes. Heavy machinery such as cranes are divided into two parts: the lower part, such as caterpillars, which moves, and the upper part, which swivels. Swivel joints connect the upper and lower sections.

The mechanism of the swivel joint enables the movement of heavy machinery such as cranes. A rotary joint with a similar mechanism may also be used.

2. Swivel Joint Sealing

Swivel joints used in high-pressure lines use O-rings or similar materials as seals on the shaft. Generally, one or two O-rings are used. For high pressure applications, multiple O-rings are used for labyrinths.

3. Piping Installation Method Using Swivel Joint Method

There is a piping installation method that utilizes the mechanism of swivel joints used for moving parts. When the fluid flowing in the piping is hot, the piping is heated and thermal elongation occurs. To absorb this thermal elongation, multiple swivel joints are used in the construction method.

By using multiple 90-degree swivel joints in a piping configuration like a U-bend, each swivel joint moves to absorb thermal elongation. In the case of stainless steel piping, this method is often used because the thermal elongation is larger than that of steel piping. There is also a construction method when thermal insulation is used, and piping is supported by rollers and rubber bands.