What Is a Board-to-Board Connector?

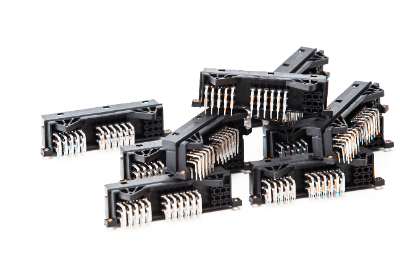

Board-to-Board Connector is a connector used for high-density mounting of printed circuit boards.

Among these connectors, those that are designed to allow the connected connectors to move in three directions (pitch, row-to-row, and mating) or to move in either direction to suppress the effects of mating misalignment are called floating connectors.

By combining a socket and a plug, the connector can move in the x-y-z three-dimensional direction, making it less susceptible to pry (shock) and misalignment.

Applications of Board To Board Connector

Board-to-Board Connectors are used in response to the recent trend toward miniaturization of equipment, and can directly connect boards together. Because of this advantage, Board-to-Board Connectors have a wide range of applications, including computers, portable information devices, digital TVs, automobiles, and industrial machinery and infrastructure.

In recent times, as electronic devices have become increasingly sophisticated, demand for more advanced and precise Board-to-Board Connectors has been increasing.

Principle of Board-to-Board Connector

Board-to-Board Connectors use pins and sockets to connect boards. The function of the pins and sockets is to connect and separate the boards through electrical contact and mechanics.

This ability to separate and join allows equipment to be configured as a unit, which is an advantage over permanent connections such as soldering or screwing. The structural design of the product and the ease of mass production enable a reduction in the total cost of ownership. It also improves maintainability, such as parts replacement and inspection, leading to stabilization of performance and quality.

How to Select Board-to-Board Connector

Board-to-Board Connectors are available in two types: the stacked type, in which the boards are stacked top to bottom, and the stand-up type, in which one of the boards is used standing up for connection. Since the shape of the connector changes depending on the direction in which the boards are connected, first consider which direction you wish to connect the boards.

There is also a bottom-entry type in which the pins penetrate from the underside of the connector. While they have the disadvantage of low mounting density, the distance between boards can be set freely. Because of this characteristic, they are used in products that have heat-generating components on separate boards.

When selecting Board-to-Board Connectors, it is necessary to confirm that the current value, withstand voltage, insulation, etc. meet the circuit specifications. In the case of circuits that require micro level and high reliability, it is also important to check the material.

Other Information on Board-to-Board Connector

1. Advantages of Board-to-Board Connector

Board-to-Board Connectors are used when additional circuits can no longer be placed on the printed circuit board during the design process. Other times, when several boards with slightly different functions are combined into one board, the boards with different functions are treated as optional boards.

The Board-to-Board Connector enables the use of a single type of board to realize the functions of multiple products by installing and removing optional boards. Normally, cables are used to connect boards to boards, but when boards are connected by cables in this way, the space occupied by the board in the equipment becomes large.

Board-to-Board Connectors are useful in meeting the need for miniaturization, since this is an obstacle when miniaturizing products. This connector can be used when circuits do not fit on a single board, when boards of different sizes are mounted, or when boards need to be joined together because of the miniaturization of the product.

2. Cautions for Board-to-Board Connector

When joining boards, it is necessary to make sure that the joints of the boards match each other in terms of the number of pins, etc. In addition, connectors only have the function of joining boards together and do not have a large mechanical support force for the boards.

Therefore, a separate mechanism to support the board with screws or other means is required. Although this connector facilitates maintenance of the board, careful handling is required to prevent excessive force from being applied to the board and damaging it when the connector is removed.