What Is a Return Roller?

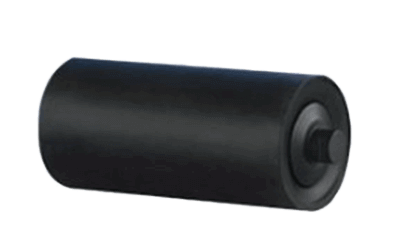

A return roller is a mechanical component used to support the belt on the return side of a conveyor.

The belt portion of a conveyor has a carrier side, which carries the load and uses carrier rollers. The return side uses return rollers.

There are various sizes of return rollers to match the belt width of the conveyor, so you can select the one suitable for the width of the belt you are using.

Uses of Return Rollers

Belt conveyors have a section called the return side, where the belt sent from the conveyor side returns. Return rollers are installed on the return side.

There are several types of return rollers. Various shapes are available, such as for preventing falling steel, spiral shape, and hanging type, allowing you to select a roller specialized for your application.

Principle of Return Rollers

In belt conveyors, rollers are attached and used to wrap the belt around a frame.

There are two types of rollers: head rollers, which are mounted at the very tip, and tail rollers, which are mounted at the very back. Snap rollers, which adjust the angle of winding, are attached near the head roller.

The rotation of these rollers feeds the conveyor belt and keeps it moving. For the belt to circulate without slipping, it must be able to catch the outgoing belt. Return rollers are necessary for this purpose.

The side to which the outgoing belt returns is called the return side, and the return roller is installed here to support the returning belt.